Injection valve

A technology of injection valve and valve body, which is applied in the direction of fuel injection device, fuel injection valve driven by fluid pressure, charging system, etc., can solve problems such as large leakage, achieve large wall thickness, improve compressive strength, optimal The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

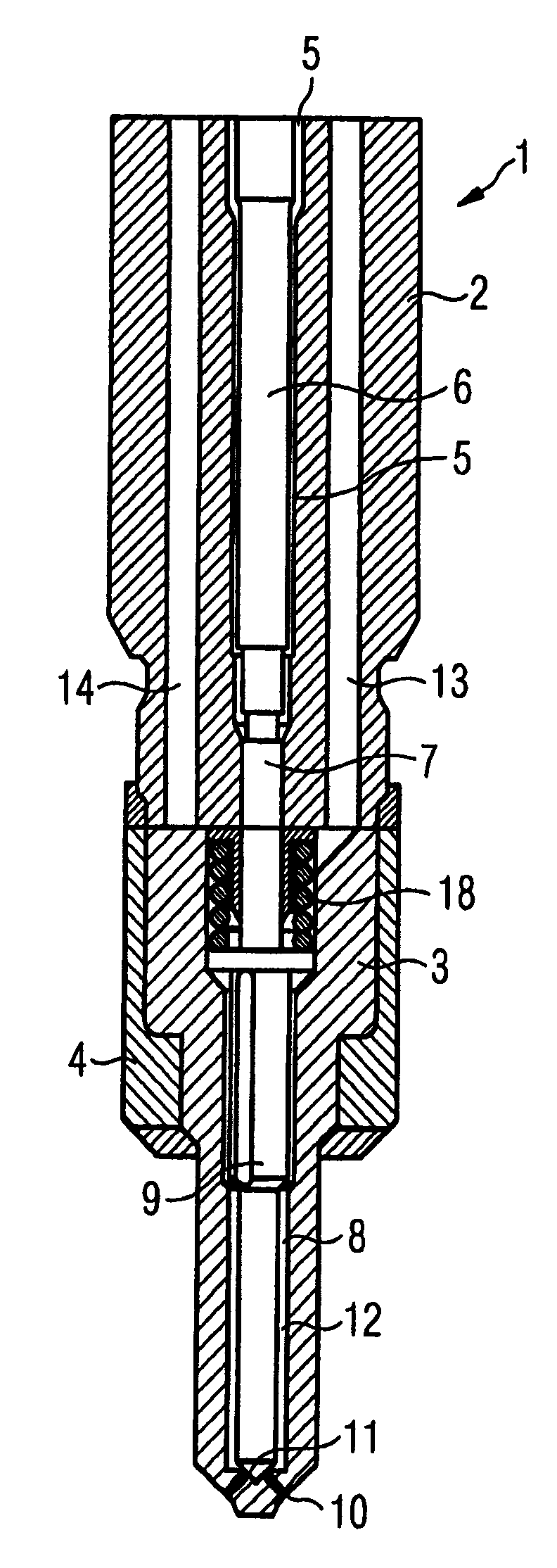

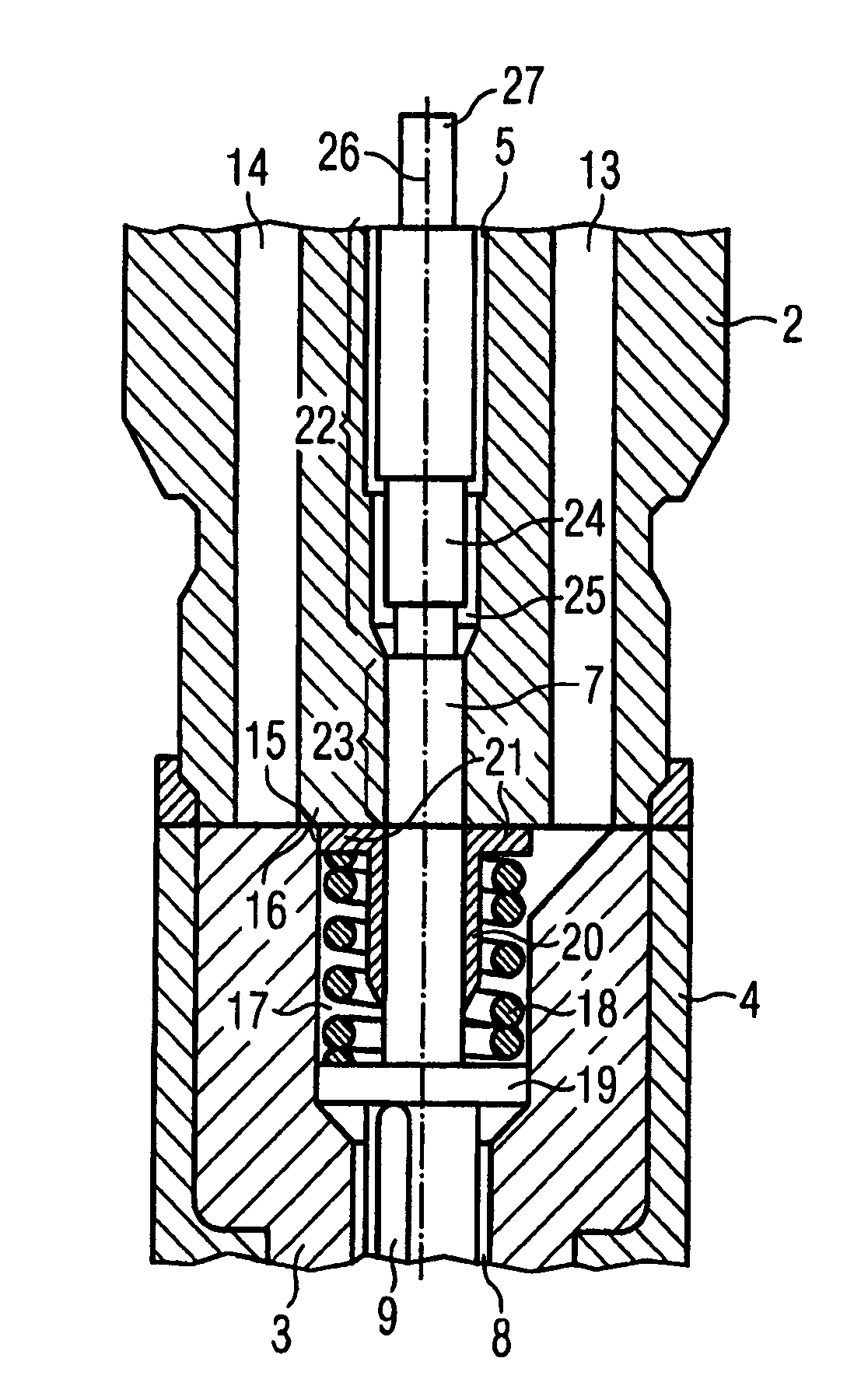

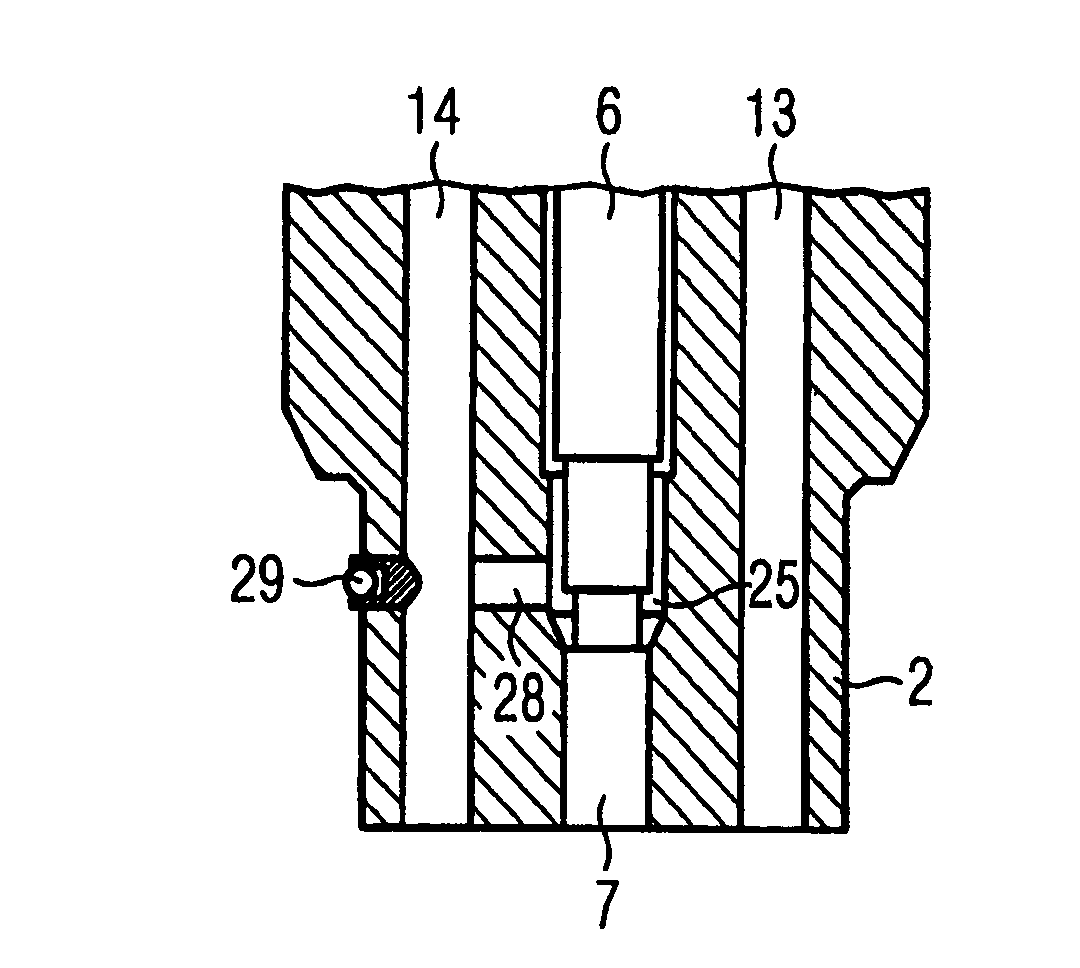

[0022] figure 1 It is a schematic illustration of the lower part of the injection valve 1 with the valve body 2 and the nozzle body 3 . The valve body 2 is located directly on the nozzle body 3 and is clamped with the valve body 2 by the nozzle clamping nut 4 . Opened in valve body 2 is a first bore 5 which is arranged along the longitudinal axis of injector 1 . A control piston 6 and a stroke adjustment screw 7 are arranged in the first bore 5 .

[0023] Opened in the nozzle body 3 is a second bore 8 in which a nozzle needle 9 is arranged axially displaceable. An injection opening 10 is provided at the lower end of the nozzle body 3 , wherein a sealing seat 11 is provided upstream in the flow direction on the inner side of the nozzle body 3 , which can be closed off by the nozzle needle 9 . A nozzle chamber 12 is provided between the nozzle needle 9 and the nozzle body 3 , which communicates with a fuel line 13 . Furthermore, a leakage line 14 is provided in the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com