Automatic and continuous drying machine

A dryer and automatic technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of low automation control, large labor demand, poor drying effect, etc., to improve drying efficiency and improve drying efficiency. The effect of reducing drying effect, equipment investment and labor input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below; any person familiar with the technical field can easily think of changes or replacements within the technical scope disclosed in the present invention, All should be covered within the scope of protection of the invention. Therefore, the protection scope of the present invention should be determined by the protection scope of the claims.

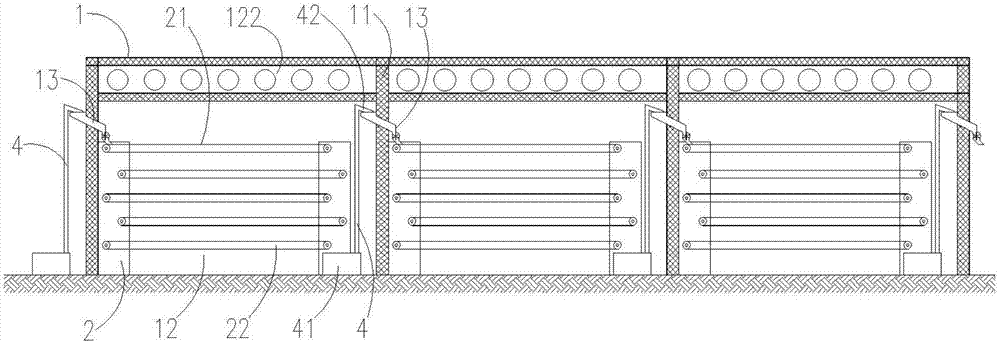

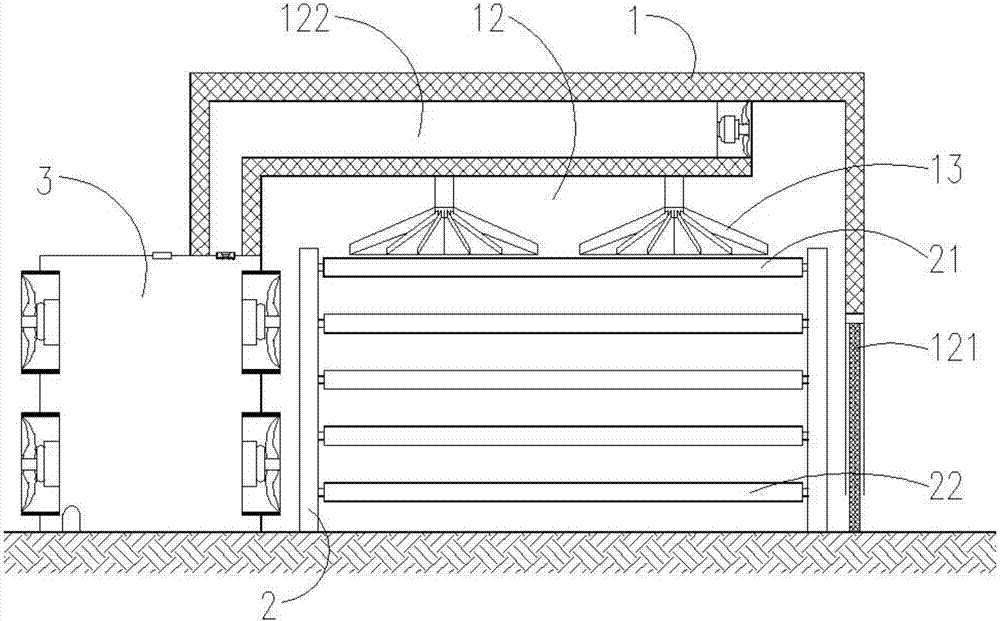

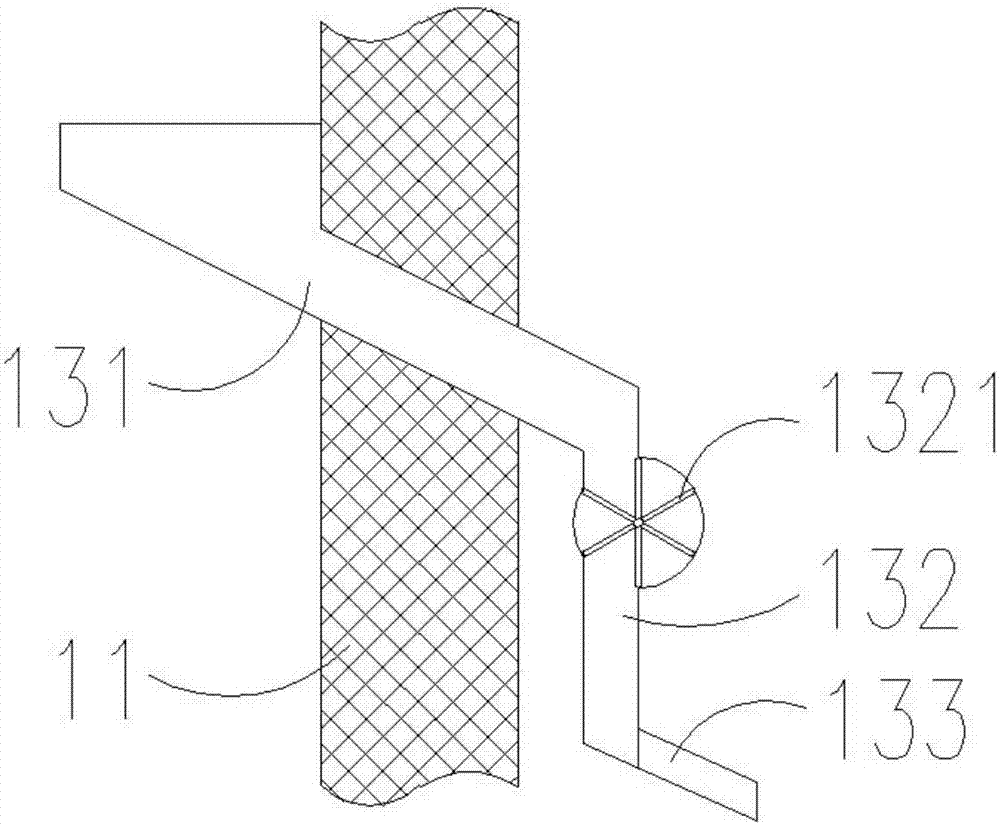

[0022] as attached figure 1 and 2 As shown, in the automatic continuous drying machine of the present invention, the box body 1 is arranged as a cuboid with a closed heat preservation structure, and the inside of the box body 1 is divided into three airtight independent working rooms 12 by heat insulation partitions 11 from front to back; the box body 1 The feeding device 13 is installed on the front side, the box body 1 and the insulation partition 11; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com