Large-tow carbon fiber oiling agent

A technology of tow carbon fiber and carbon fiber, which is applied in the field of large tow carbon fiber oil, can solve the problems of non-permanent antistatic and poor heat resistance, and achieve the effects of brittleness, good heat resistance and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, the preparation of compound A

[0048] Add 100Kg of modified aminopropyl silicone oil with a kinematic viscosity of 80cp and an ammonia value of 0.18mmol / g to the reactor, add 50Kg of isopropanol, 5Kg of xylene, and 1.8Kg of epoxy resin E51, heat up to 85°C to 90°C, and reflux After 4 hours, the solvent was evaporated under reduced pressure, and finally the pressure was reduced to 133Pa, and the temperature was raised to 120°C to remove small molecules to obtain Compound A-1 with a kinematic viscosity of 230cp and an ammonia value of 0.18mmol / g.

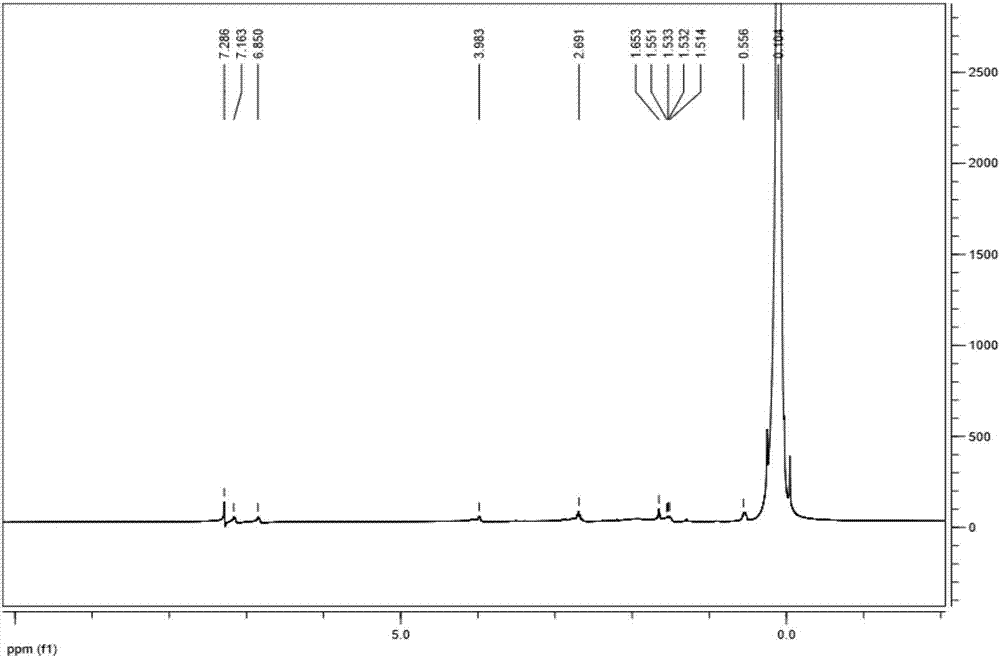

[0049] Compound A-1 H NMR spectrum such as figure 1 As shown, the solvent is CDCl 3 . Among them, the chemical shift δ=0.104 is Si-CH 3 Hydrogen on, δ=0.556 is Si-CH 2 On hydrogen, δ=1.514~1.551 is NHCH 2 CH 2 CH 2 Middle CH 2 The hydrogen above, δ=1.653 is the CH connected between the two benzene rings and the middle carbon in the structure of bisphenol A 3 On hydrogen, δ=2.691 is NHCH 2 CH 2 CH 2 CH...

Embodiment 2

[0050] Embodiment 2, the preparation of compound A

[0051] Add 100Kg of modified aminopropyl silicone oil with a kinematic viscosity of 130cp and an ammonia value of 0.16mmol / g to the reactor, add 50Kg of isopropanol, 5Kg of xylene, and 1.0Kg of epoxy resin E51, heat up to 85°C to 90°C, and reflux After 4 hours, the solvent was evaporated under reduced pressure, and finally the pressure was reduced to 133Pa, and the temperature was raised to 120°C to remove small molecules to obtain compound A-2 with a kinematic viscosity of 330cp and an ammonia value of 0.16mmol / g.

Embodiment 3

[0052] Embodiment 3, the preparation of quaternary ammonium salt block silicone oil

[0053] Add 116g of N,N,N',N'-tetramethylethylenediamine, 126g of acetic acid and 100g of water into the reactor, stir at room temperature for 0.5h, then raise the temperature to 50°C, and dropwise add 2Kg of terminal glycidyloxy The mixture of propyl epoxy silicone oil (number average molecular weight 4000) and 1.1Kg isopropanol is heated to 85°C-90°C, refluxed for 6h, the solvent is evaporated under reduced pressure, and finally the pressure is reduced to 133Pa, and the temperature is raised to 120°C to remove small Molecules to obtain quaternary ammonium salt block silicone oil B-1.

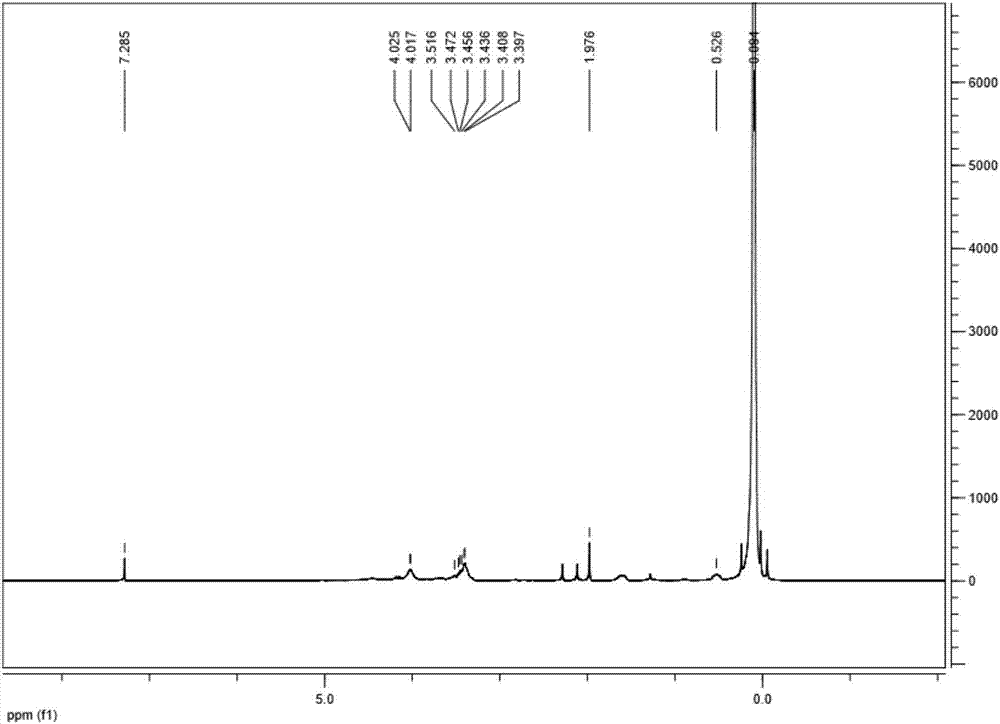

[0054] Compound B-1 H NMR spectrum such as figure 2 As shown, the solvent is CDCl 3 , where the chemical shift δ=0.094 is Si-CH 3 Hydrogen on, δ=0.526 is Si-CH 2 On hydrogen, δ=1.976 is CH in acetic acid 3 The hydrogen above, δ=3.397~3.516 is the CH connected to nitrogen in the quaternary ammonium salt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com