Preparation method of high-purity ZnO/BiVO4 heterogeneous micro-ribbon

A micro-strip, high-purity technology used in the field of micro-strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Respectively take by weighing the polyvinylpyrrolidone (PVP) 0.7g that molecular weight is 1300000 and the PVP0.3g that molecular weight is 40000 and be dissolved in the mixed solvent that contains 2.5g dehydrated alcohol, 2.0g glacial acetic acid and 2.5g dimethylformamide, room temperature After stirring and mixing for 3 hours, add 1.21g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), 0.662g bis(acetylacetonate) vanadium oxide (VO(acac) 2 ) and 1.0 g of diisopropyl azodicarboxylate (foaming agent, DIPA) and continued stirring for 3 hours to obtain a precursor spinning solution.

[0049] After the spinning solution was left to stand, 5ml was measured and injected into a plastic needle tube, and placed on an electrospinning machine, and the injection speed was set at 1ml / h. The metal needle is used as the electrospinning anode, and the barbed wire is used as the cathode of the receiving material. The distance between the anode and the cathode is 20cm. Electrospin...

Embodiment 2

[0053] The only difference from Example 1 is that in this example, when the solid-state precursor microribbon deposits ZnO in the atomic layer deposition (ALD) system, after 300 cycles, the others are the same as in Example 1, and will not be repeated here. .

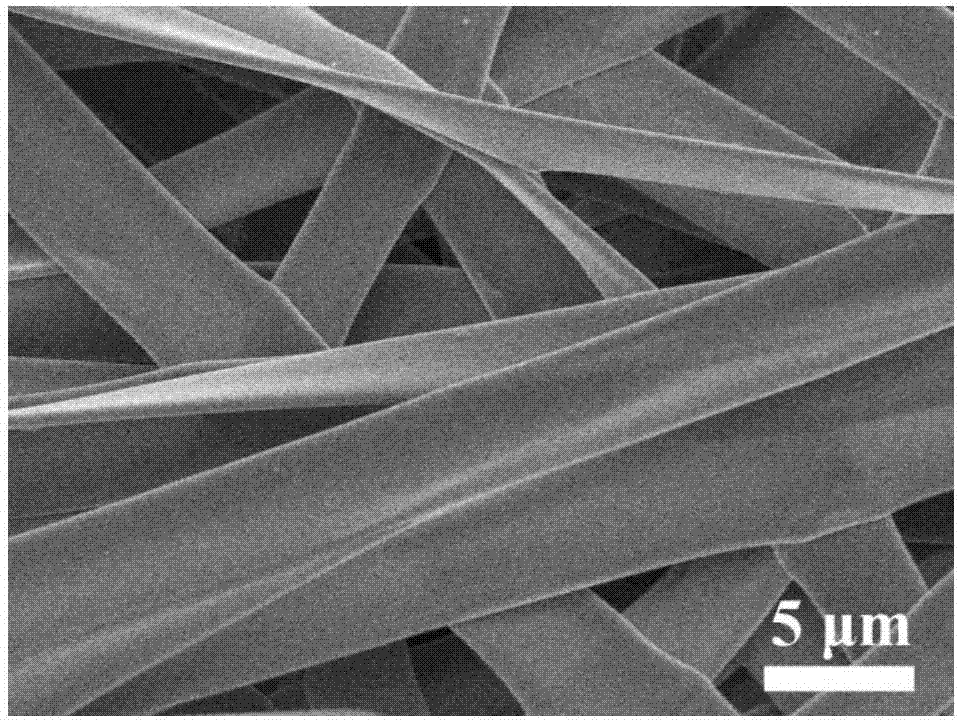

[0054] A typical scanning electron microscope (SEM) image of the as-prepared nanofibrous material at different magnifications is as follows: Figure 10 and Figure 11 , indicating that the prepared material is a microribbon. Figure 12 Its corresponding X-ray diffraction pattern shows that the prepared microribbons are ZnO / BiVO 4 composite material. Figure 13 Its corresponding element distribution energy spectrum (EDS) diagram shows that ZnO / BiVO 4 ZnO and BiVO in Heterogeneous Microbelts 4 The content ratio is 5:1. Comparing the results of Example 1, it can be seen that when the number of cycles of ALD deposition of ZnO is reduced to 300, the final material prepared by calcination is still a micro-ribbon materia...

Embodiment 3

[0056] The only difference from Example 1 is that in this example, when the solid precursor microbelt deposits ZnO in the atomic layer deposition (ALD) system, after 500 cycles, the others are the same as in Example 1, and will not be repeated here. .

[0057] A typical scanning electron microscope (SEM) image of the as-prepared nanofibrous material at different magnifications is as follows: Figure 14 and Figure 15 , indicating that the prepared material is a microribbon. Figure 16 Its corresponding X-ray diffraction pattern shows that the prepared microribbons are ZnO / BiVO 4 composite material. Figure 17 Its corresponding element distribution energy spectrum (EDS) diagram shows that ZnO / BiVO 4 ZnO and BiVO in Heterogeneous Microbelts 4 The content ratio is 9:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com