Blast furnace coal spraying-iron ore sintering experiment simulation device

An experimental simulation and blast furnace coal injection technology, applied in the field of metallurgy and chemical industry, can solve the problems of large floor space, inconvenient movement of experimental devices, limited laboratory area, etc., and achieve the effect of avoiding experimental errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

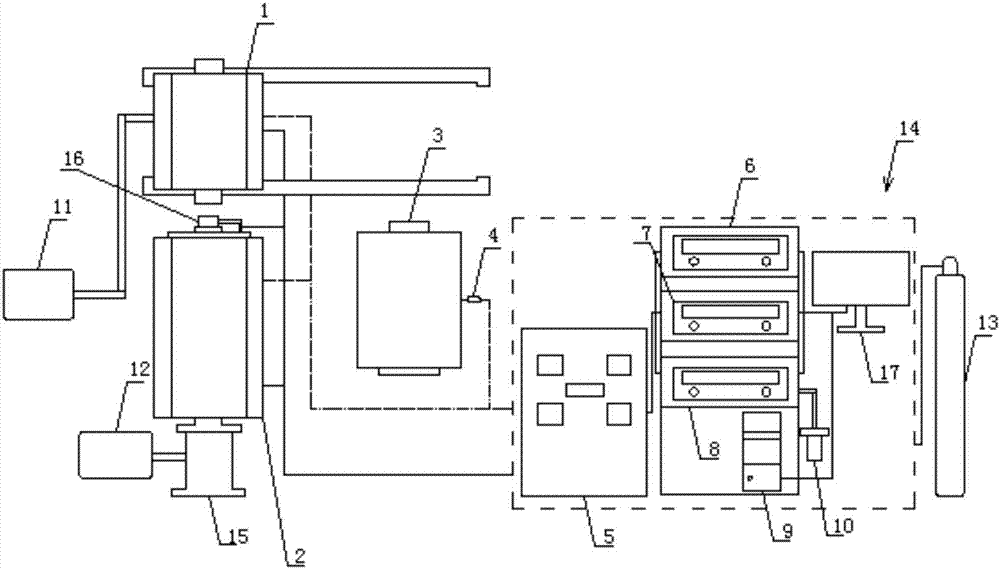

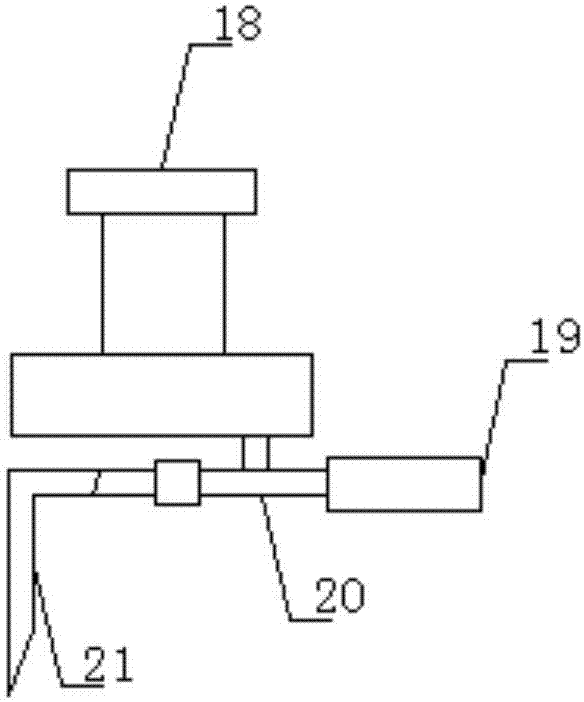

[0034] In a specific embodiment, such as figure 1 As shown, a blast furnace coal injection-iron ore sintering experimental simulation device includes a pulverized coal combustion furnace 2, a sintering furnace 3, a hot blast stove 1 connected to the pulverized coal combustion furnace 2 or sintering furnace 3, a mobile hot blast stove 1 to the coal Pulverized coal combustion furnace 2 or sintering furnace 3 connected support frame, respectively connected pulverized coal combustion furnace 2, sintering furnace 3 and hot blast stove 1 control and data acquisition system 14 and gas cylinder 13 for supplying gas to control and data acquisition system 14. The bottom of the hot blast stove 1 is provided with a corundum gas outlet pipe, and the pulverized coal combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com