Buffer material for hot press and application of buffer material

A buffer material and hot press technology, applied in the field of buffer materials, can solve problems such as deterioration, high production costs, and increased restrictions on hot pressing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

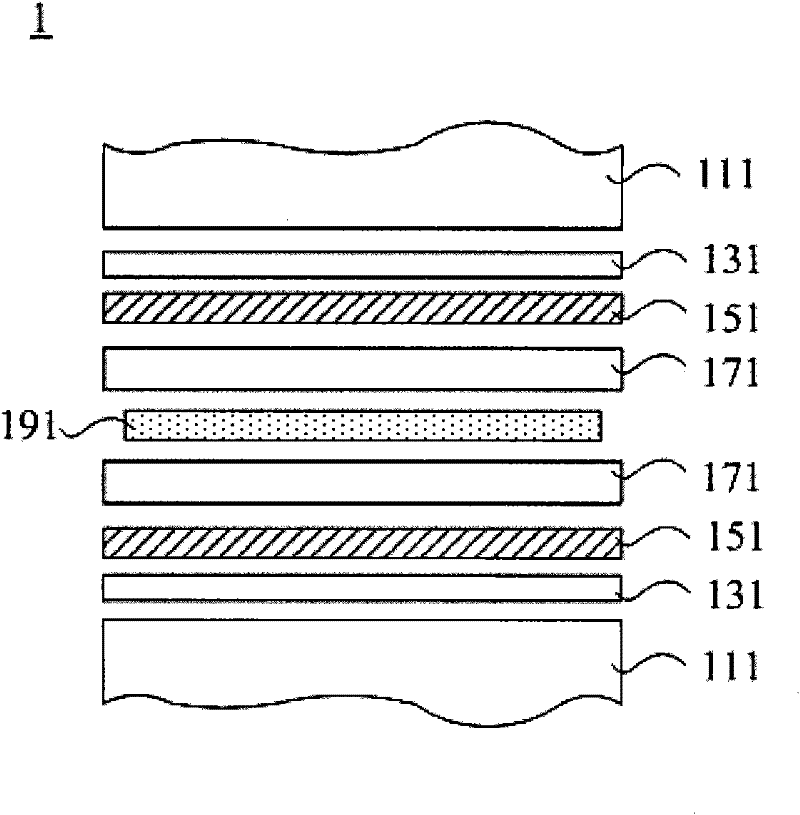

[0041] Use MPIA fiber (glass transition temperature about 270 ° C) as the material of the base layer, the fixed thread and the first fiber, and the fixed thread is used to fix the first fiber on the base layer by knitting to form a density of about 0.4 g / cm3. And the buffer material with a basis weight of about 1400 g / m2 (thickness about 3.5 mm), and the buffer material is placed in the figure 1 Heat press 1 shown. The temperature of the heating plate 111 is set to about 200°C, so as to provide a heat treatment temperature of about 180°C on the surface of the steel sheet 171 in contact with the laminate material 191. When the temperature of the steel sheet 171 reaches the heat treatment temperature of about 180°C, the A pressure of about 8 kg / cm 2 is applied to the heating plates 111 on both sides, so that the steel plate 171 is brought into contact with the laminated plate material 191, and the hot pressing procedure of the base plate material is carried out for about 90 minu...

Embodiment 1b

[0043] The hot pressing procedure of the laminate material 191 was performed with the same hot pressing machine and hot pressing conditions as in Example 1a, but the basis weight of the buffer material was adjusted to be about 1600 g / m2 (thickness about 4.0 mm). In the first hot pressing procedure, the heating rate of the surface of the steel sheet 171 in contact with the laminate material 191 from normal temperature to a heat treatment temperature of about 180°C was measured; and the hot pressing procedure was repeated, and in the 200th hot pressing procedure, The temperature increase rate of the surface of the steel sheet 171 in contact with the laminate material 191 from normal temperature to a heat treatment temperature of about 180°C. The measurement results are recorded in Table 1.

Embodiment 1c

[0045] The hot pressing procedure of the laminate material 191 was performed with the same hot pressing machine and hot pressing conditions as in Example 1a, but the basis weight of the buffer material was adjusted to about 1800 g / m2 (thickness about 5.3 mm). In the first hot pressing procedure, the heating rate of the surface of the steel sheet 171 in contact with the laminate material 191 from normal temperature to a heat treatment temperature of about 180°C was measured; and the hot pressing procedure was repeated, and in the 200th hot pressing procedure, The temperature increase rate of the surface of the steel sheet 171 in contact with the laminate material 191 from normal temperature to a heat treatment temperature of about 180°C. The measurement results are recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com