Boiler drying temperature control module and its control method

A technology for controlling components and boiler furnace walls, which is applied in the direction of reducing gas emissions and lining repair. It can solve the problems of difficulty in controlling the initial temperature, large linear expansion of high-alumina bricks, and the speed cannot be too fast, so as to ensure the quality of the oven, The temperature field is uniformly distributed and the effect of avoiding temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

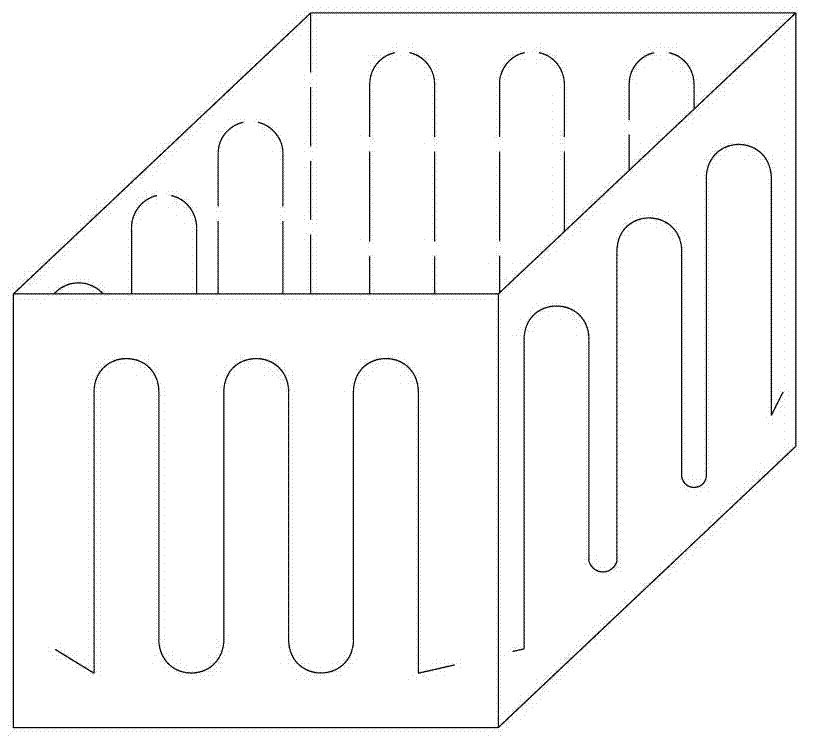

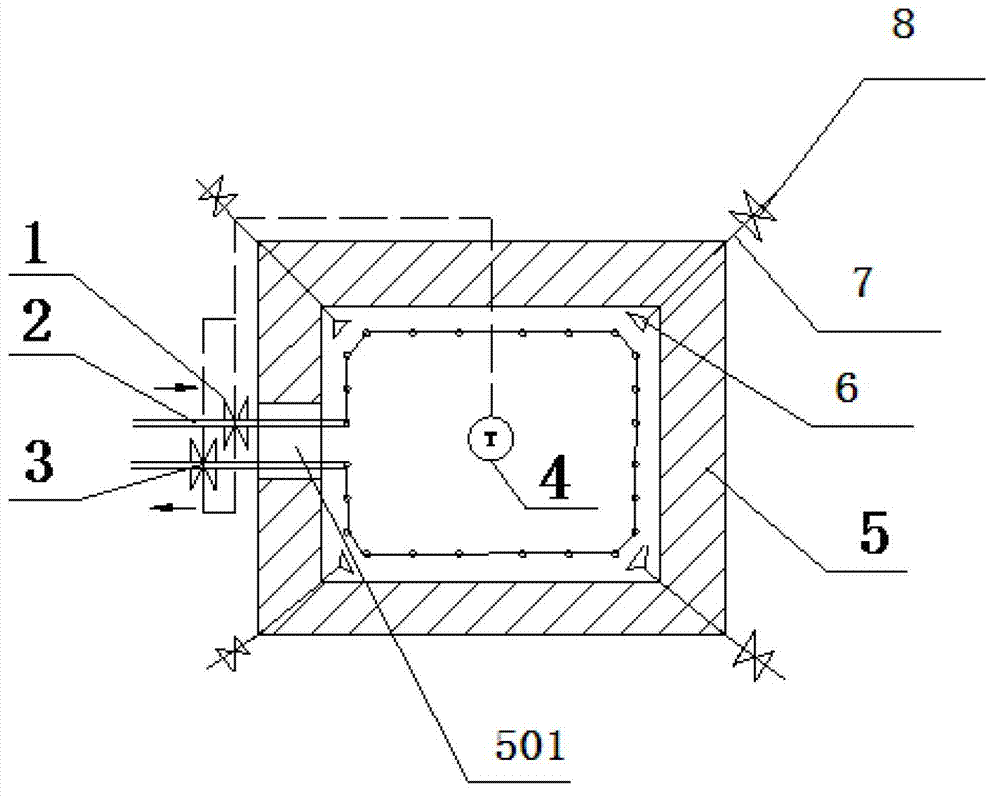

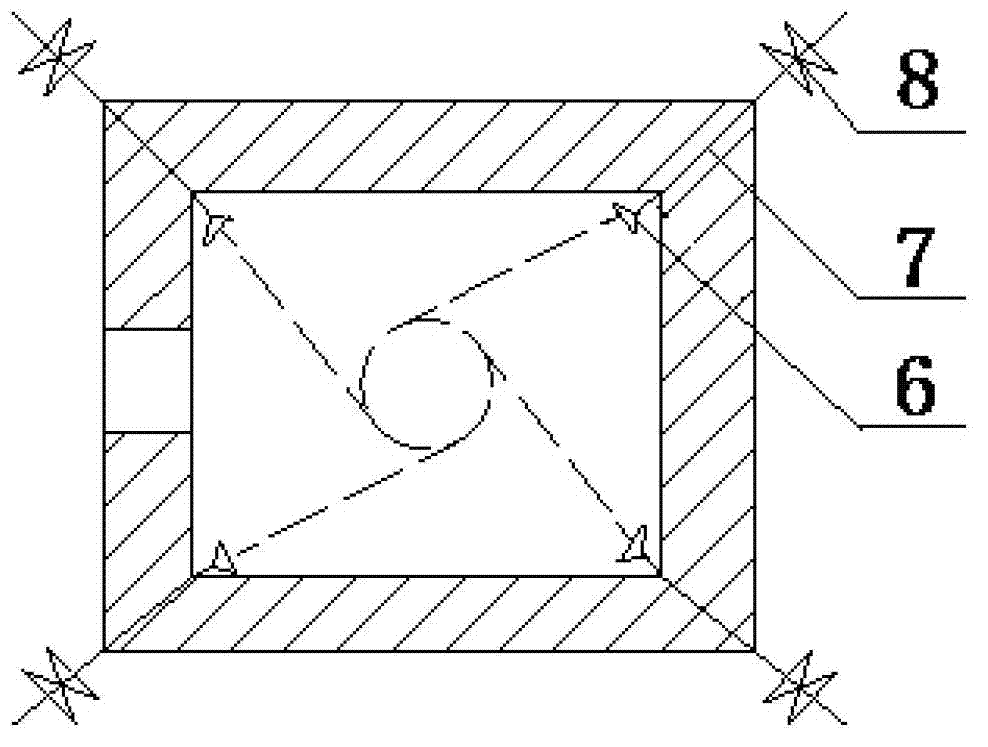

[0036] The first-stage oven adopts a high-load oven (high-load oven: the average daily temperature rise ranges from 35°C to 45°C, excluding 35°C), with a daily temperature rise of 40°C, and the oven lasts for 4 days. The steam cooling pipe 2 of the oven adopts a three-dimensional arrangement, and the steam is superheated steam, and its parameters are as follows: P=1.4MPa, T=230°C, M=1200Kg / h. At the same time, through feedback control, that is, fine-tuning the furnace temperature through the first flow control valve 1 and the second flow control valve 3, it is ensured that the oven is strictly in accordance with the oven curve (oven curve: the heating rate, heat preservation Time, the graph represented by time-temperature is called the oven curve). In the second stage, the burner 6 is baked with natural gas at a small fire. The temperature inside the boiler wall 5 rises by 30°C every day, and the oven lasts for 2 days. This stage is also controlled by small flow feedback, that...

Embodiment 2

[0039] The first-stage oven adopts a medium-load oven (medium-load oven: the average daily temperature rise ranges from 25°C to 35°C, excluding 25°C), with a daily temperature rise of 30°C, and the oven lasts for 4.5 days. The steam cooling pipe 2 of the oven adopts a three-dimensional arrangement, and the steam is superheated steam, and its parameters are as follows: P=1.6MPa, T=250°C, M=1000Kg / h. At the same time, through feedback control, that is, through the first flow control valve 1 and the second flow control valve 3, the furnace temperature is fine-tuned to ensure that the oven is strictly in accordance with the oven curve. In the second stage, the burner 6 is baked by natural gas with a small fire. The temperature inside the boiler wall 5 rises by 40°C every day, and the oven lasts for 1.5 days. This stage is also controlled by small flow feedback, that is, through the third flow control valve 8 pairs The furnace temperature is controlled.

[0040] After the first an...

Embodiment 3

[0042] The first-stage oven adopts a low-load oven (low-load oven: the average daily temperature rise ranges from 15°C to 25°C, excluding 15°C), with a daily temperature rise of 25°C, and the oven lasts for 5 days. The steam cooling pipe 2 of the oven adopts a three-dimensional arrangement, and the steam is superheated steam, and its parameters are as follows: P=1.8MPa, T=270°C, M=800Kg / h. At the same time, through feedback control, that is, through the first flow control valve 1 and the second flow control valve 3, the furnace temperature is fine-tuned to ensure that the oven is strictly in accordance with the oven curve. In the second stage, the burner 6 is baked with natural gas on a small fire. The temperature inside the boiler wall 5 rises by 50°C every day, and the oven lasts for one day. This stage is also controlled by small flow feedback, that is, through the third flow control valve 8 pairs The furnace temperature is controlled.

[0043] After the first and second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com