Preparation method of calcium carbonate/polymer core-shell structure

A technology of core-shell structure and polymer, which is applied in the field of preparing nano-calcium carbonate/polymer core-shell structure, which can solve the problems that it is difficult to uniformly coat nano-materials, it is difficult to obtain nano-calcium carbonate, and it is prone to empty coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

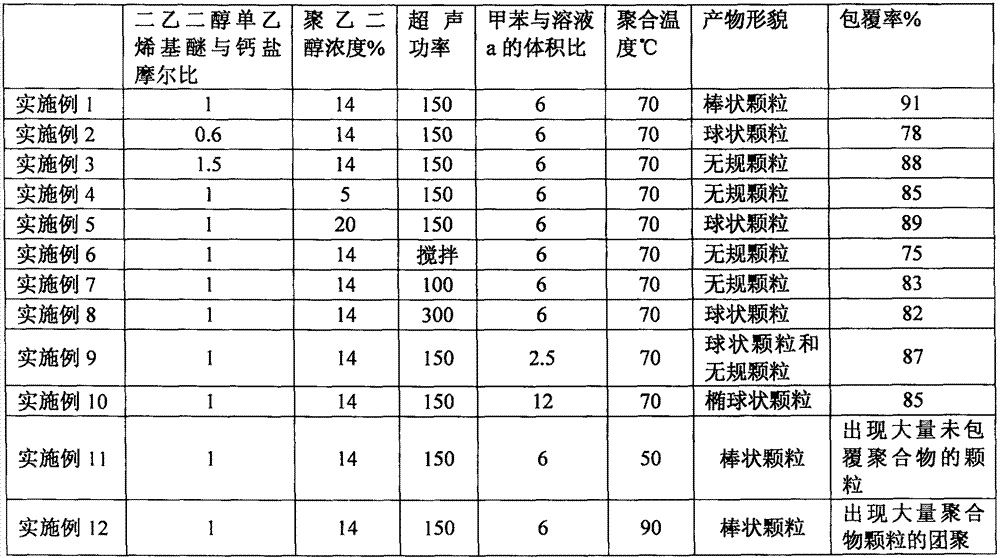

Embodiment 1

[0024] 1) Prepare solution a: Dissolve calcium nitrate in deionized water so that the concentration of calcium salt is 1.2mol / L, add diethylene glycol monovinyl ether, the molar ratio of calcium salt to diethylene glycol monovinyl ether 1:1, stir evenly;

[0025] 2) Preparation of solution b: dissolving sodium carbonate in deionized water;

[0026] 3) Dissolve polyethylene glycol in toluene, the mass concentration of polyethylene glycol in toluene is 14%, add solution a, the volume ratio of toluene to solution a is 6:1, stir at 50°C for 1h, cool to room temperature , under ultrasonication, add solution b, ultrasonically react for 15min, the ultrasonic power is 150W, and the molar ratio of calcium ion and carbonate ion in the reaction system is 1:1.1;

[0027] 4) Collect the product, centrifuge and wash;

[0028] 5) The washed product is dispersed in carbon tetrachloride, azobisisoheptanonitrile is added, heated to 70° C. and stirred for 3 hours to obtain a calcium carbonate / ...

Embodiment 2

[0030] 1) Prepare solution a: Dissolve calcium nitrate in deionized water so that the concentration of calcium salt is 1.2mol / L, add diethylene glycol monovinyl ether, the molar ratio of calcium salt to diethylene glycol monovinyl ether 1:0.6, stir evenly;

[0031] 2) Preparation of solution b: dissolving sodium carbonate in deionized water;

[0032] 3) Dissolve polyethylene glycol in toluene, the mass concentration of polyethylene glycol in toluene is 14%, add solution a, the volume ratio of toluene to solution a is 6:1, stir at 50°C for 1h, cool to room temperature , under ultrasonication, add solution b, ultrasonically react for 15min, the ultrasonic power is 150W, and the molar ratio of calcium ion and carbonate ion in the reaction system is 1:1.1;

[0033] 4) Collect the product, centrifuge and wash;

[0034] 5) The washed product is dispersed in carbon tetrachloride, azobisisoheptanonitrile is added, heated to 70° C. and stirred for 3 hours to obtain a calcium carbonat...

Embodiment 3

[0036] 1) Prepare solution a: Dissolve calcium nitrate in deionized water so that the concentration of calcium salt is 1.2mol / L, add diethylene glycol monovinyl ether, the molar ratio of calcium salt to diethylene glycol monovinyl ether 1:1.5, stir evenly;

[0037] 2) Preparation of solution b: dissolving sodium carbonate in deionized water;

[0038] 3) Dissolve polyethylene glycol in toluene, the mass concentration of polyethylene glycol in toluene is 14%, add solution a, the volume ratio of toluene to solution a is 6:1, stir at 50°C for 1h, cool to room temperature , under ultrasonication, add solution b, ultrasonically react for 15min, the ultrasonic power is 150W, and the molar ratio of calcium ion and carbonate ion in the reaction system is 1:1.1;

[0039] 4) Collect the product, centrifuge and wash;

[0040] 5) The washed product is dispersed in carbon tetrachloride, azobisisoheptanonitrile is added, heated to 70° C. and stirred for 3 hours to obtain a calcium carbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com