Microwave medium ceramic material and preparation method thereof

A microwave dielectric ceramic and ceramic technology, which is applied in the field of electronic ceramics and its manufacturing, can solve the problems of narrow dielectric constant adjustment range, abnormal growth of crystal grains, insufficient density of crystal grains, etc., and achieves low price, simple preparation method, and sintering. The effect of a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

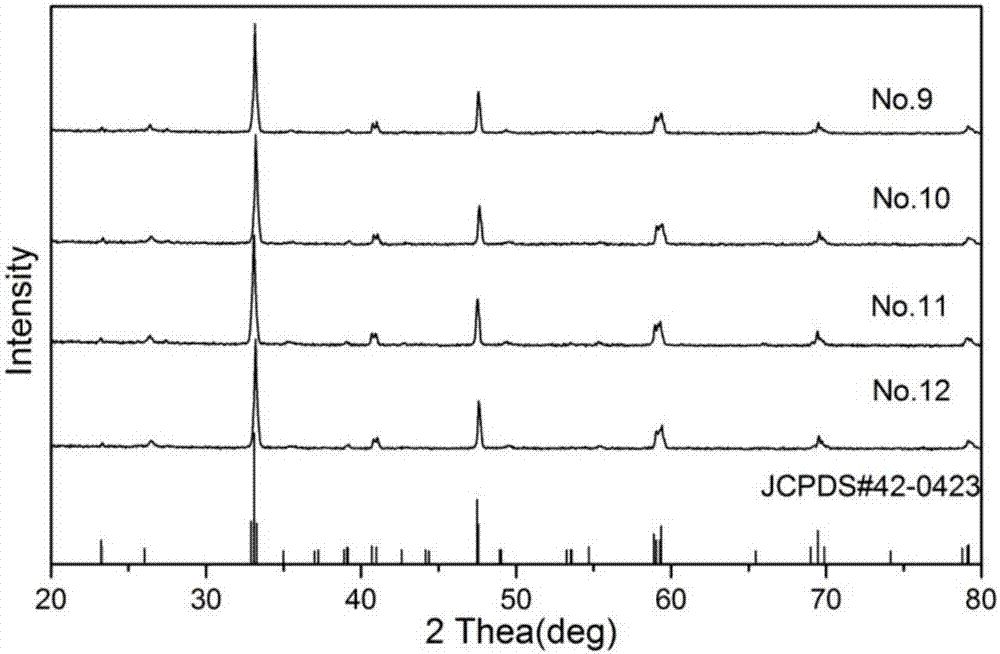

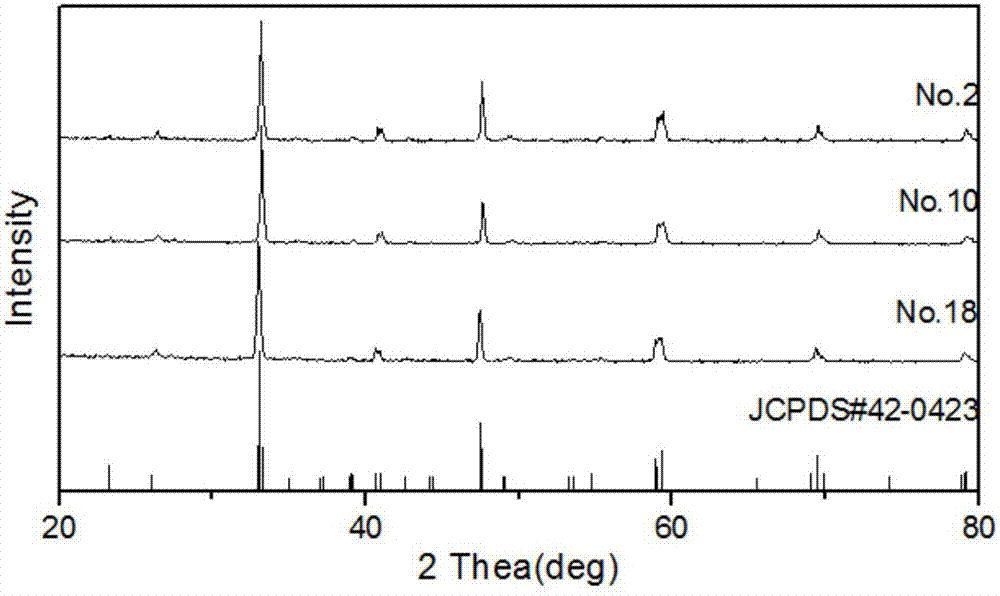

Image

Examples

Embodiment 1

[0057] Step 1: batching; With 15.604g calcium carbonate, 2.436g lithium carbonate, 41.507g titanium dioxide, 38.052g samarium oxide according to general chemical formula (Ca 0.6 Li 0.14 SM 1.26 )TiO 3 Dosing is carried out to form the first mixture; Lanthanum oxide and aluminum oxide are mixed according to LaAlO 3 Perform batching to form a second mixture, the percentages of the second mixture and the first mixture accounting for the total mass are respectively 97.6% and 2.4%;

[0058] Step 2: ball milling; using zirconia balls as the ball milling medium, the mixture obtained in step 1 is ground according to the mass ratio of mixture: balls: deionized water is 1:5:1.5, and the milling time is 6 hours to obtain a uniformly mixed Ball abrasive;

[0059] Step 3: drying and sieving; drying the ball mill material obtained in step 2 at 100°C and passing it through a 60-mesh sieve to obtain a dry powder;

[0060] Step 4: Pre-sintering; the dry powder obtained in step 3 is pre-si...

Embodiment 2

[0066] In this embodiment, except that the sintering temperature in step 8 is 1335° C., other operations are the same as in embodiment 1.

Embodiment 3

[0068] In this embodiment, except that the sintering temperature in step 8 is 1350° C., other operations are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com