Cr2O3/ZTA composite powder and ceramic and preparing method thereof

A technology of composite powder and composite ceramics, which is applied in the field of preparation of inorganic materials, can solve the problems that ZTA ceramic devices cannot meet, and achieve the effect of high hardness and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] a) According to the steps of preparing ZTA powder, weigh alumina powder and 3Y-ZrO 2 Powder, of which alumina powder 85g, 3Y-ZrO 2 Powder 15g, Cr(NO 3 ) 3 .9H 2 O crystal 6.84g, of which 6.84gCr(NO 3 ) 3 .9H 2 Cr in O 3+ The molar concentration of 0.5g Cr2 o 3 Cr in 3+ The molar concentrations are equal, and these three powders are poured into a polytetrafluoroethylene ball mill tank;

[0053] b) Add 280 g of zirconia balls as a ball milling medium to a polytetrafluoroethylene ball milling tank, and add 120 g of absolute ethanol as a ball milling medium. The mixture was ball milled on a planetary mill for 24 hours and then mixed to obtain a slurry for subsequent use;

[0054] c) Pour the mixed slurry into a plastic container, put it in an oven and bake it at 85°C for 12 hours, then pour the dried mixed powder into a zirconia crucible, and heat it in an electric furnace at 500°C Keep warm for 1-2 hours and then cool with the furnace to get Cr 2 o 3 / ZTA comp...

Embodiment 2

[0058] a) According to the steps of preparing ZTA powder, weigh alumina powder and 3Y-ZrO 2 Powder, wherein alumina powder 80g, 3mol% Y 2 o 3 -ZrO 2 Powder 20g, Cr(NO 3 ) 3 .9H 2 O crystal 10.94g, of which 10.94gCr(NO 3 ) 3 .9H 2 Cr in O 3+ The molar concentration of 0.8g Cr 2 o 3 Cr in 3+ The molar concentrations are equal, and these three powders are poured into a polytetrafluoroethylene ball mill tank;

[0059] b) Add 280 g of zirconia balls as a ball milling medium to a polytetrafluoroethylene ball milling tank, and add 120 g of absolute ethanol as a ball milling medium. The mixture was ball milled on a planetary mill for 24 hours and then mixed to obtain a slurry for subsequent use;

[0060] c) Pour the mixed slurry into a plastic container, put it in an oven and bake it at 85°C for 12 hours, then pour the dried mixed powder into a zirconia crucible, and heat it in an electric furnace at 500°C Keep warm for 1-2 hours and then cool with the furnace to get Cr ...

Embodiment 3

[0064] Basically the same as embodiment 1, the difference is only that Cr 2 o 3 The content is 0.08wt.%.

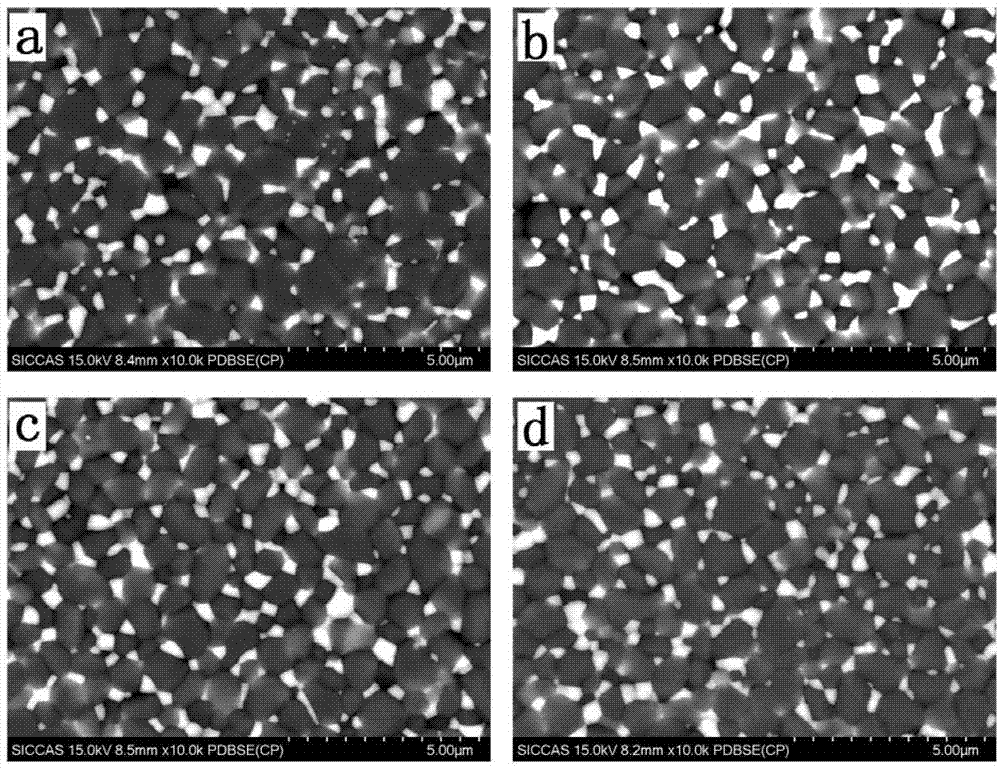

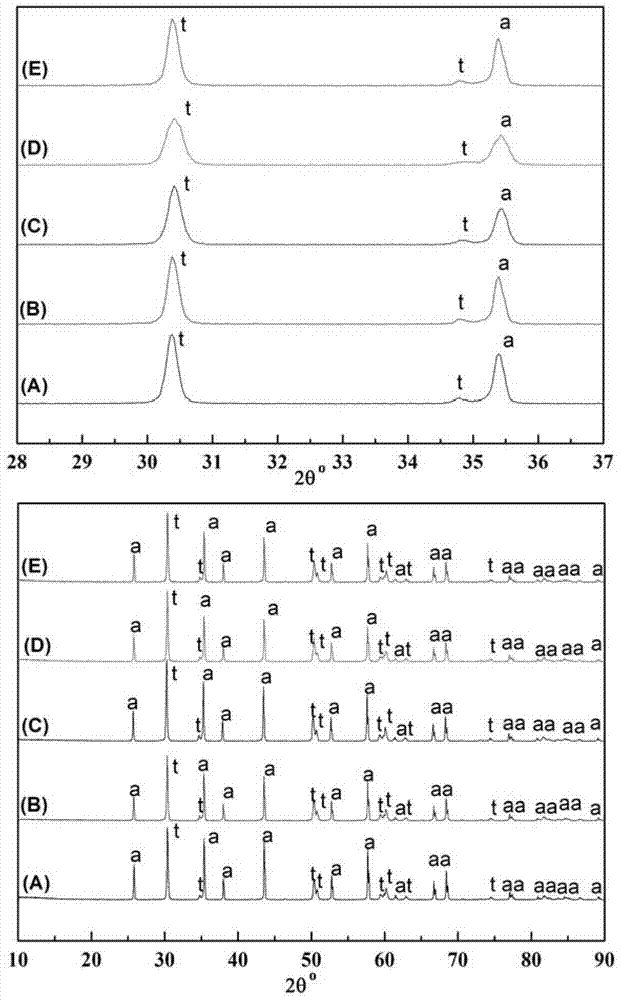

[0065] The SEM images of the prepared ZTA ceramics are as follows figure 1 As shown in (a), it can be seen that zirconia is uniformly dispersed in alumina, and there are almost no pores. The XRD pattern of the prepared ZTA ceramics is as follows figure 2 As shown in (B), it can be seen that it is pure tetragonal zirconia and hexagonal alumina, without Cr 2 o 3 The presence. After testing, the ZTA ceramic has a hardness of 1772MPa and a toughness of 4.52MPa.m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com