Rapid manufacturing method for metal 3D printing injection mold of structure facing gradient space

An injection mold and 3D printing technology, applied in the field of metal 3D printing, can solve the problems of low manufacturing efficiency, small weight of molding machines, precision and efficiency can not be taken into account at the same time, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with drawings and embodiments, but the present invention is not limited to this example.

[0018] A method for rapidly manufacturing a metal 3D printing injection mold oriented to a gradient space structure, comprising the following steps:

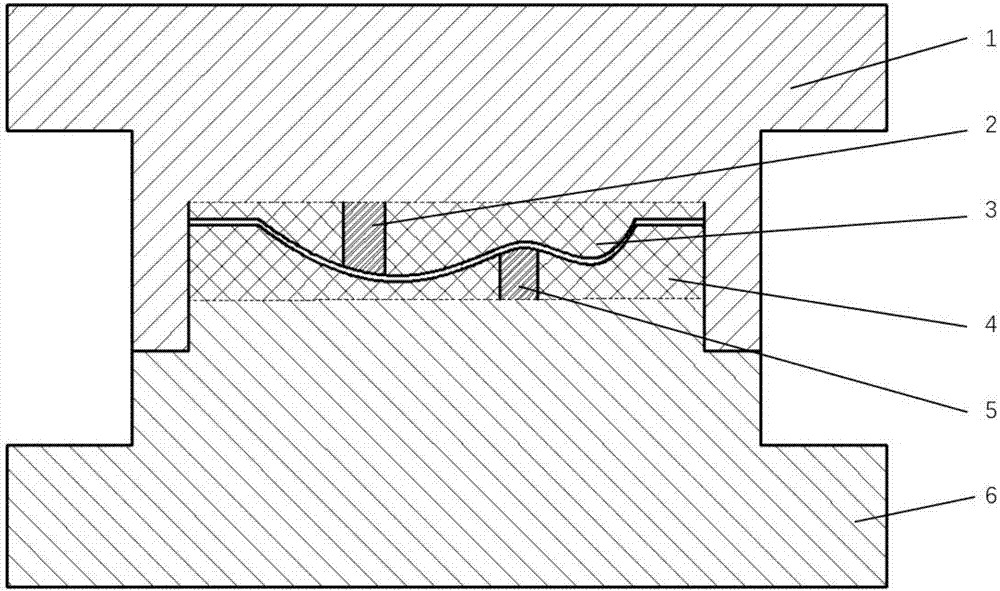

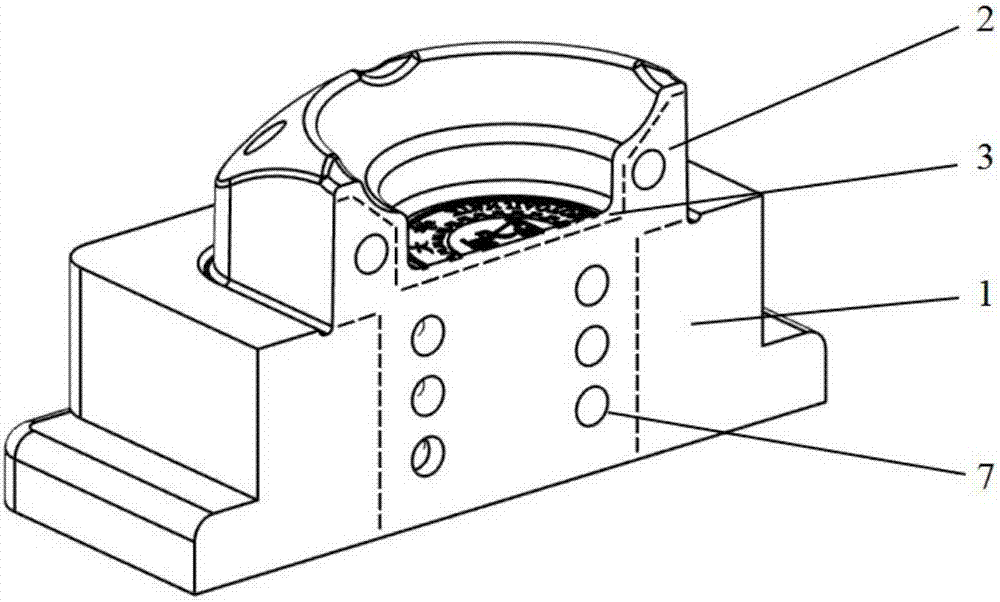

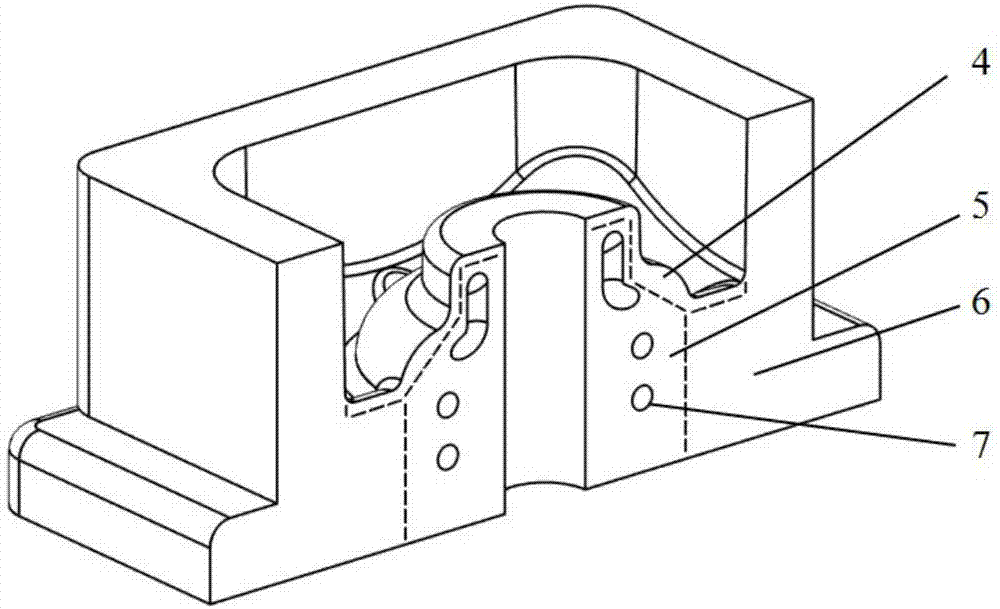

[0019] 1) Mold design is carried out according to the characteristics of the injection molded parts. At the same time, according to the service characteristics and molding characteristics of the injection mold during the injection molding process, the injection mold is partitioned, decoupling optimization is carried out, and the injection mold is decomposed into the support area of the punch. 1. The function of the punch Area 2, punch forming area 3, die forming area 4, die function area 5 and die support area 6, such as figure 1 , figure 2 , image 3 As shown, the punch and the die are provided with conformal cooling channels 7, and materials are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com