Separated two pbase flow liquid level controller

A liquid level controller, a split-type technology, applied in liquid level control, non-electric variable control, control/regulation systems, etc., can solve the problem of the cumbersome structure of the liquid level controller, the inflexibility and convenience of system connection, maintenance and layout, etc. problems, to achieve the effect of easy installation, layout and maintenance, good adjustment performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

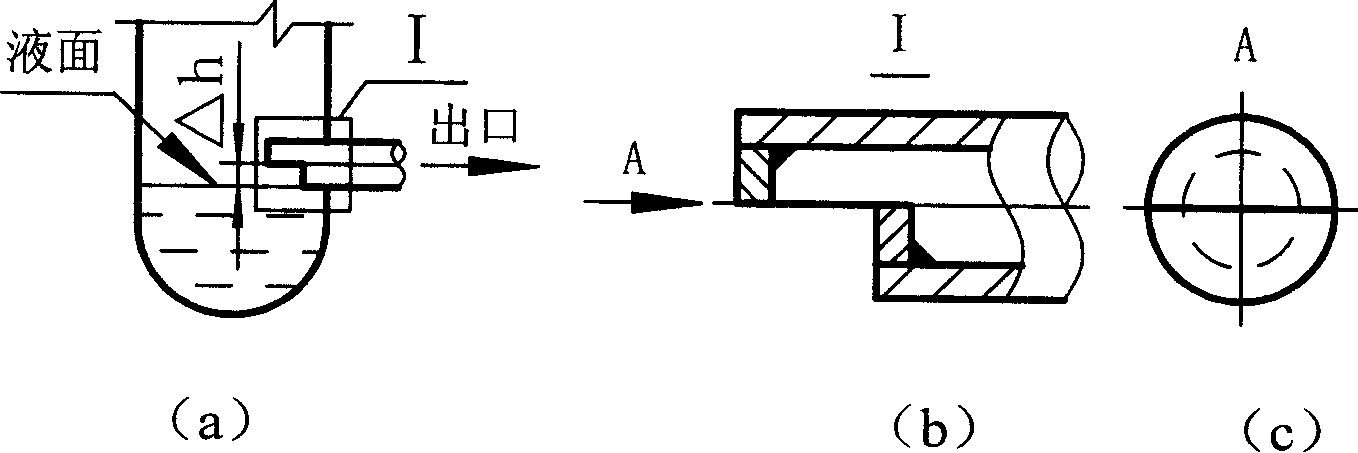

[0018] The structure of the split two-phase flow controller is as follows: figure 1 shown. It consists of industrial container (liquid level control object) 1, steam flow transmitter 2, throttling and pressure reducing element 3, two-phase flow controller 4, tee 8, three gate valves 5, 7, 9 and other equipment. The specific connection is described as follows. The drain pipe 12 at the bottom of the industrial container 1 is connected to the first gate valve 9, and the first gate valve 9 is connected to the throttling and pressure-reducing element 3. The controller 4 is connected to the pipeline leading out from the steam flow transmitter 2, and the two-phase flow controller 4 is connected to the second gate valve 5 and the outlet pipe 6 behind. A bypass pipe 10 is connected between the discharge pipe 12 at the bottom of the industrial container 1 and the outlet pipe 6 behind the gate valve 5, and the third gate valve 7 is connected in the pipe.

[0019] Its liquid level adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com