Preparation method and application of auxiliary metal-doped Cu-SAPO-18 catalyst

A metal doping and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve simple preparation process, improve catalytic activity, and promote redispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Dissolve 18g of ammonium nitrate in 100ml of deionized water to form an ammonium nitrate solution, then slowly add 5g of H-SAPO-18 molecular sieve into the above solution, exchange at 80°C for 6h, filter, wash, and Dry at 90°C to get 6gNH 4 -SAPO-18 molecular sieve;

[0023] (2) 0.3g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 8ml of deionized water to form a copper nitrate solution, and then 3g of NH 4 - SAPO-18 molecular sieves were slowly added to the above solution, ultrasonicated for 2 hours, allowed to stand at room temperature for 24 hours, dried at 100°C, and calcined at 600°C for 6 hours to obtain 3g of Cu-SAPO-18 catalyst powder;

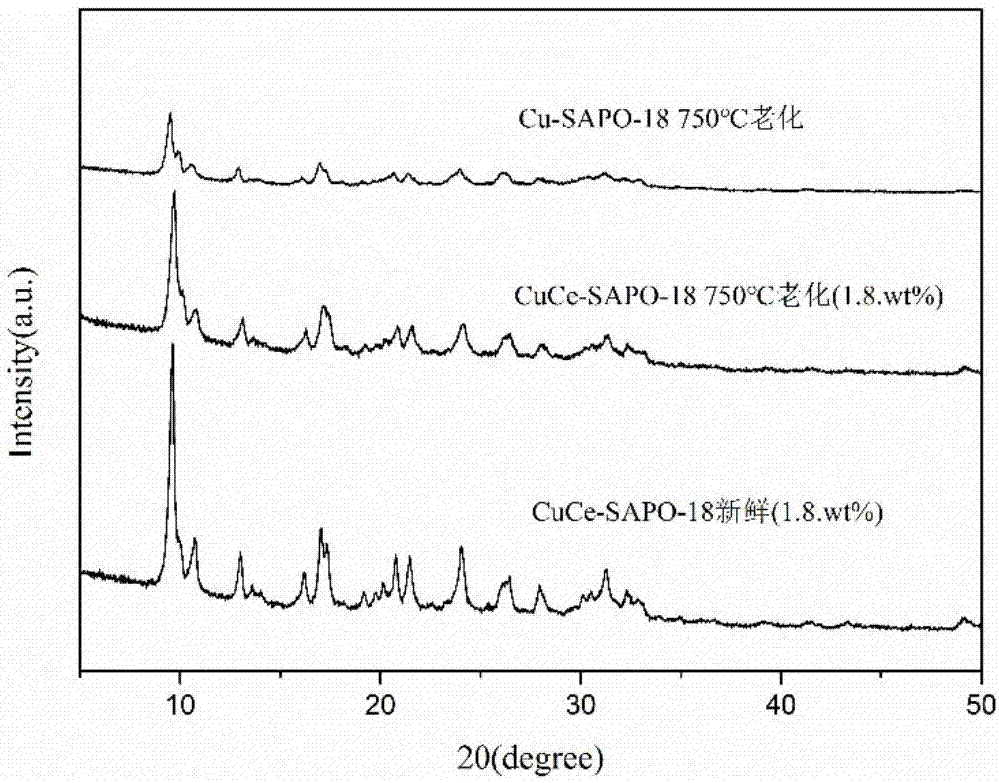

[0024] (3) 0.142g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in 4ml of deionized water to form a cerium nitrate solution, and then 2.5g of Cu-SAPO-18 catalyst powder was added to the above solution. After ultrasonication for 2h, it was allowed to stand at room temperature for 24h and dried at 100°C to obtain The solid was calcined...

Embodiment 2-5

[0026](1) Dissolve 18g of ammonium nitrate in 100ml of deionized water to form an ammonium nitrate solution, then slowly add 5g of H-SAPO-18 molecular sieve into the above solution, exchange at 80°C for 6h, filter, wash, and Dry at 90°C to get NH 4 - SAPO-18 molecular sieves.

[0027] (2) 0.3g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 8ml of deionized water to form a copper nitrate solution, and then 3g of NH 4 - SAPO-18 molecular sieves were slowly added to the above solution, ultrasonicated for 2 hours, left standing at room temperature for 24 hours, dried at 100°C, and calcined at 600°C for 6 hours to obtain Cu-SAPO-18 catalyst.

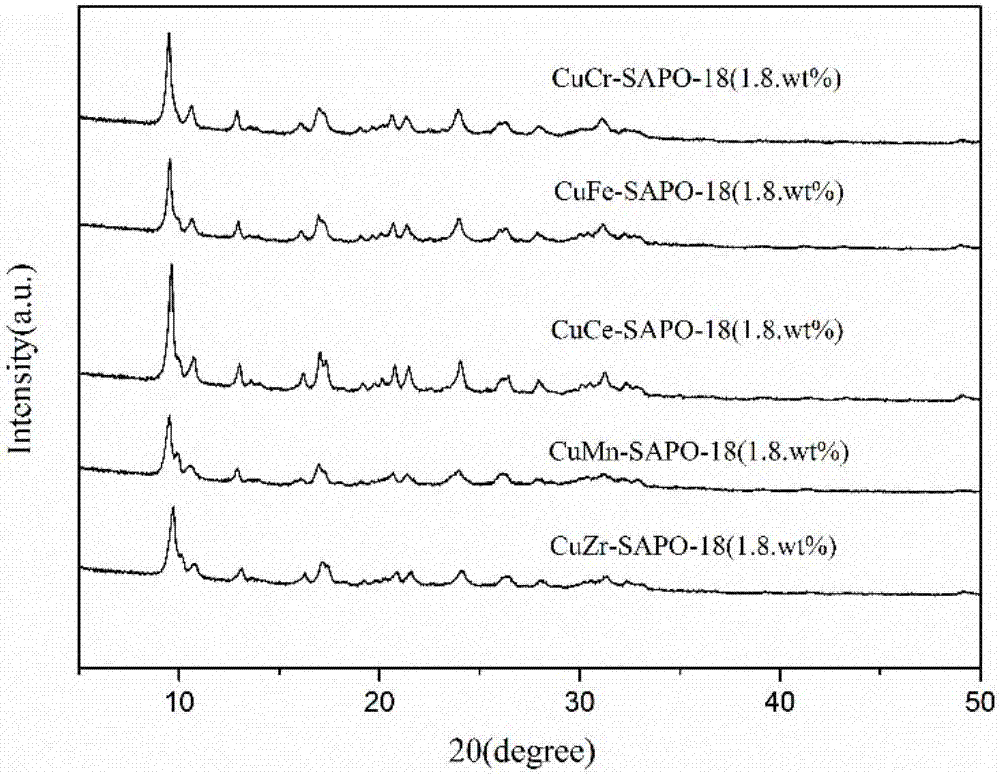

[0028] (3) 0.216g of Zr(NO 3 ) 4 ·5H 2 O, 0.332g of Fe(NO 3 ) 3 9H 2 O, 0.210g of Mn(NO 3 ) 2 4H 2 O, 0.354g of Cr(NO 3 ) 3 9H 2 O was dissolved in 4ml of deionized water to form nitrate solutions of Zr, Fe, Mn, and Cr respectively, and then 2.5g of Cu-SAPO-18 catalyst was added to the above solution. After ultrasonication for 2h, it...

Embodiment 6-9

[0030] (1) Dissolve 18g of ammonium nitrate in 100ml of deionized water to form an ammonium nitrate solution, then slowly add 5g of H-SAPO-18 molecular sieve into the above solution, exchange at 80°C for 6h, filter, wash, and Dry at 90°C to get NH 4 - SAPO-18 molecular sieves.

[0031] (2) 0.3g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 8ml of deionized water to form a copper nitrate solution, and then 3g of NH 4 - SAPO-18 molecular sieves were slowly added to the above solution, ultrasonicated for 2 hours, left standing at room temperature for 24 hours, dried at 100°C, and calcined at 600°C for 6 hours to obtain Cu-SAPO-18 catalyst.

[0032] (3) 0.047g, 0.094g, 0.142g, 0.191g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in 4ml of deionized water to form cerium nitrate solutions with different contents, and then 2.5g of Cu-SAPO-18 catalyst was added to the above solution, after ultrasonication for 2h, let stand for 24h, and dry at 100°C to obtain The solid was calcined at 600°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com