Beverage filling chamber sterilization device and method thereof

A sterilization device and filling technology, applied in the field of sterilization, can solve the problems that the beverage filling production line cannot ensure complete aseptic conditions, and achieve the effect of maintaining sterile conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment.

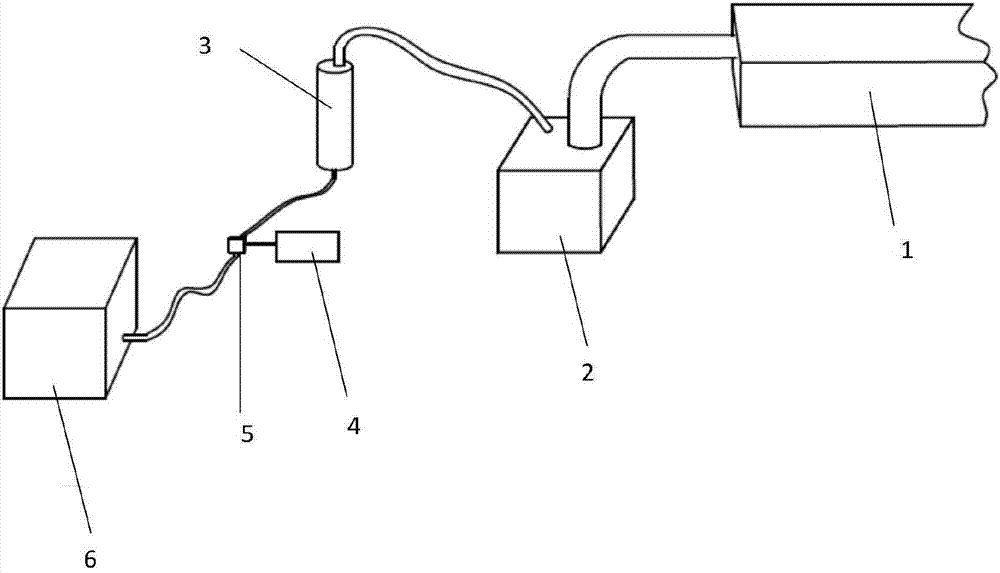

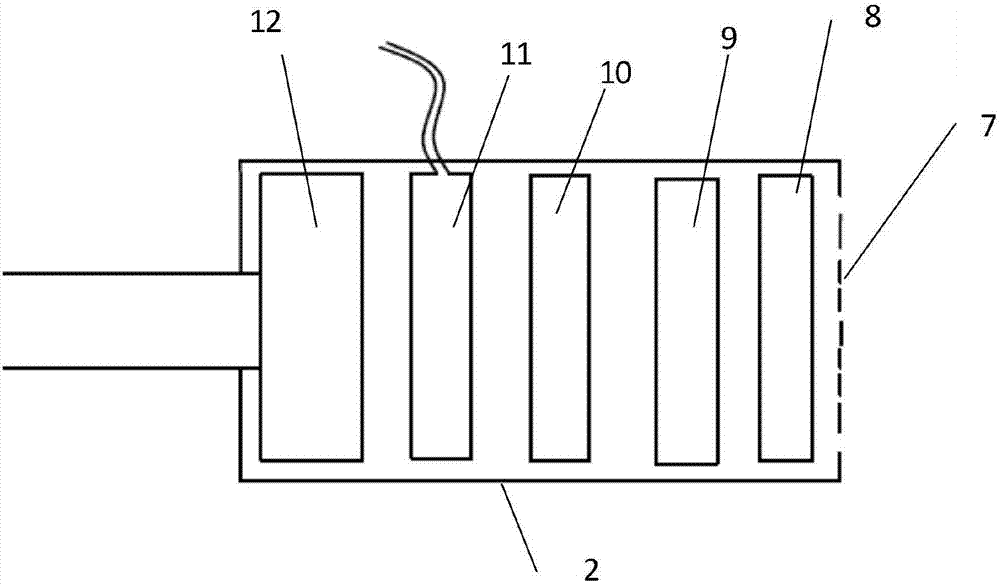

[0026] A beverage filling room sterilization device and method thereof, such as figure 1 As shown, it includes a hot wind generator 2, a vaporizer 3, a control device 4, a small vacuum pump 5 and a hydrogen peroxide solution tank 6. The invention sprays the mixed gas of sterilization to the production line regularly through the control device, so as to better ensure the completely sterile condition in the production line.

[0027] The hydrogen peroxide solution box 6 is connected with the input port of the small vacuum pump 5 . The control device 4 is connected to the control terminal of the small vacuum pump 5 through wires. Control device 4 comprises microprocessor and clock circuit, and clock circuit is connected with microprocessor, and microprocessor is the single-chip microcomputer chip of STM32 series, and single-chip microcomputer chip is respectively connected with blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com