Baking-resistant high-oil custard and its preparation method and application

A baking-resistant and sda sauce technology, which is applied in the field of food processing, can solve the problems of custard sauce with less oil content, poor baking resistance, and loss of taste, and achieve rich taste and flavor, good baking resistance and long shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

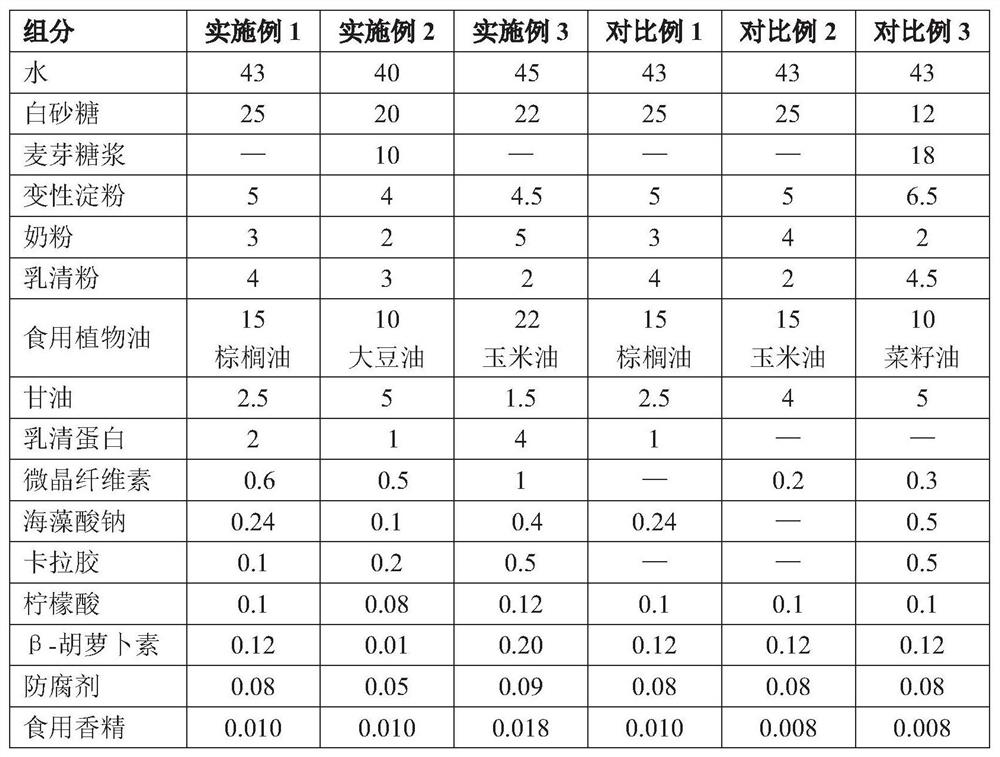

[0028] Prepare the baking-resistant high-oil custard sauce of the present invention by the formula ratio in Table 1 and the following specific industrial production steps:

[0029] 1) Add the weighed white granulated sugar, modified starch, milk powder, whey powder, whey protein, microcrystalline cellulose, sodium alginate, and carrageenan into the water and stir evenly, pass through a homogenizer, and the circulation homogenization time is 3 minutes~ 5min.

[0030] 2) Add edible vegetable oil and glycerin and stir evenly, then continue to circulate and homogenize for 7 minutes to 10 minutes, and homogenize into a smooth and delicate paste.

[0031] 3) Pump the homogeneous material into the frying pan, heat and stir with steam to fully gelatinize the starch, the temperature is 90°C-95°C, and the time is 20min-30min.

[0032] 4) Turn off the steam, add citric acid, potassium sorbate, and β-carotene, and continue to stir evenly.

[0033] 5) Finally, add edible essence, stir ev...

Embodiment 2

[0036] The process of this embodiment is basically the same as that of Example 1, the difference being that the recipe ratio and the minor adjustment of process parameters are shown in Table 1.

Embodiment 3

[0038] The process of this embodiment is basically the same as that of Embodiment 1, and the adjustment of its formula raw material ratio and process parameters is shown in Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com