Preparation method for trimethylol propane modified alkyd resin for coating

A technology of trimethylolpropane and alkyd resin, used in polyester coatings, coatings, etc., can solve the problems of high drying temperature, long baking time, easy yellowing, etc. Short baking time, good color retention and baking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preparation method of alkyd resin for coatings modified with trimethylolpropane, comprising the following steps:

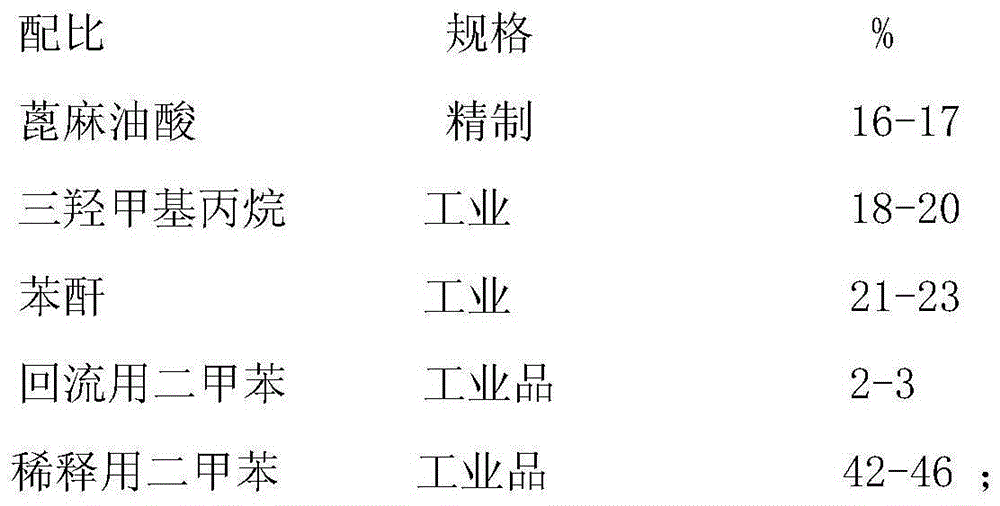

[0015] (1) Take the following component raw materials by weight percentage:

[0016]

[0017] (2) Put ricinoleic acid, trimethylolpropane, phthalic anhydride and xylene for reflux into the reaction kettle according to the formula, raise the temperature to 180°C and start reflux dehydration until the temperature rises to 230°C to maintain esterification;

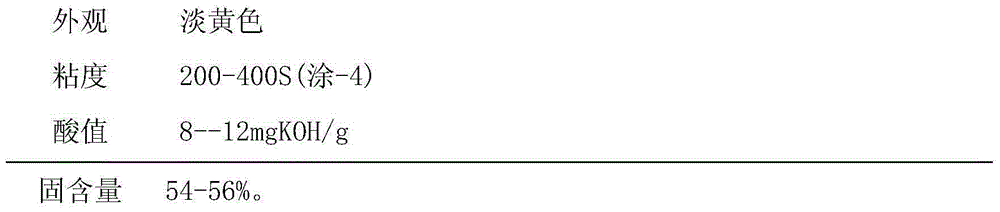

[0018] (3) When the acid value of the resin reaches 8--12mgKOH / g, and the viscosity reaches 200-400S (Tu-4), it is qualified, lower the temperature, add xylene to dilute, filter, and pack into barrels.

[0019] Modified alkyd resin quality standard of the present invention is as follows:

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com