Composite-stratum shield tunneling machine waste-soil transporting system

A transportation system and composite stratum technology, applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of easy water accumulation in the assembly operation area and easy pollution of the working environment by muck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

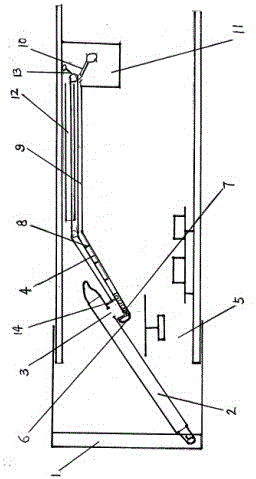

[0009] The present invention is described in detail below in conjunction with accompanying drawing:

[0010] A shield machine slag transportation system for complex strata, comprising a shield machine soil bin 1, a screw conveyor 2 connected to the shield machine soil bin 1, and a belt conveyor bridge installed below the excavation opening 3 of the screw conveyor 2 At the head end of the slope section 4, a belt conveyor trolley flat slope section 9 is arranged at the end of the belt conveyor bridge slope section 4, and a vehicle frame tail excavation port 11 is arranged at the end of the belt conveyor trolley flat slope section 9. Below the excavation opening of the screw conveyor 2, an assembly operation area 5 is arranged, and a water-retaining arc-shaped plate 6 is arranged at the head end of the slope section 4 of the belt conveyor bridge frame. A buffer rubber roller group 7 is arranged under the head belt of the transmission belt 8 on the slope section 4 of the bridge fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com