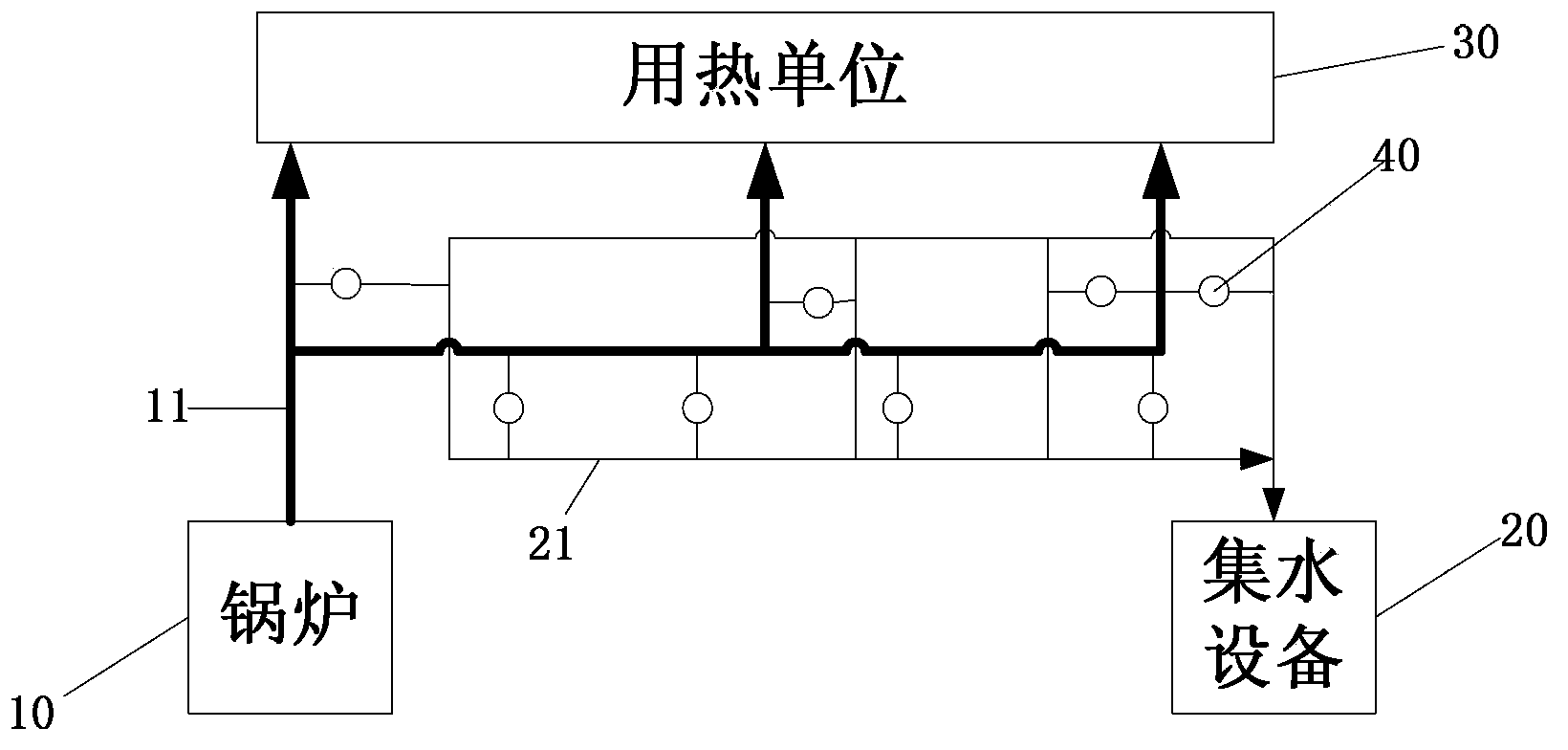

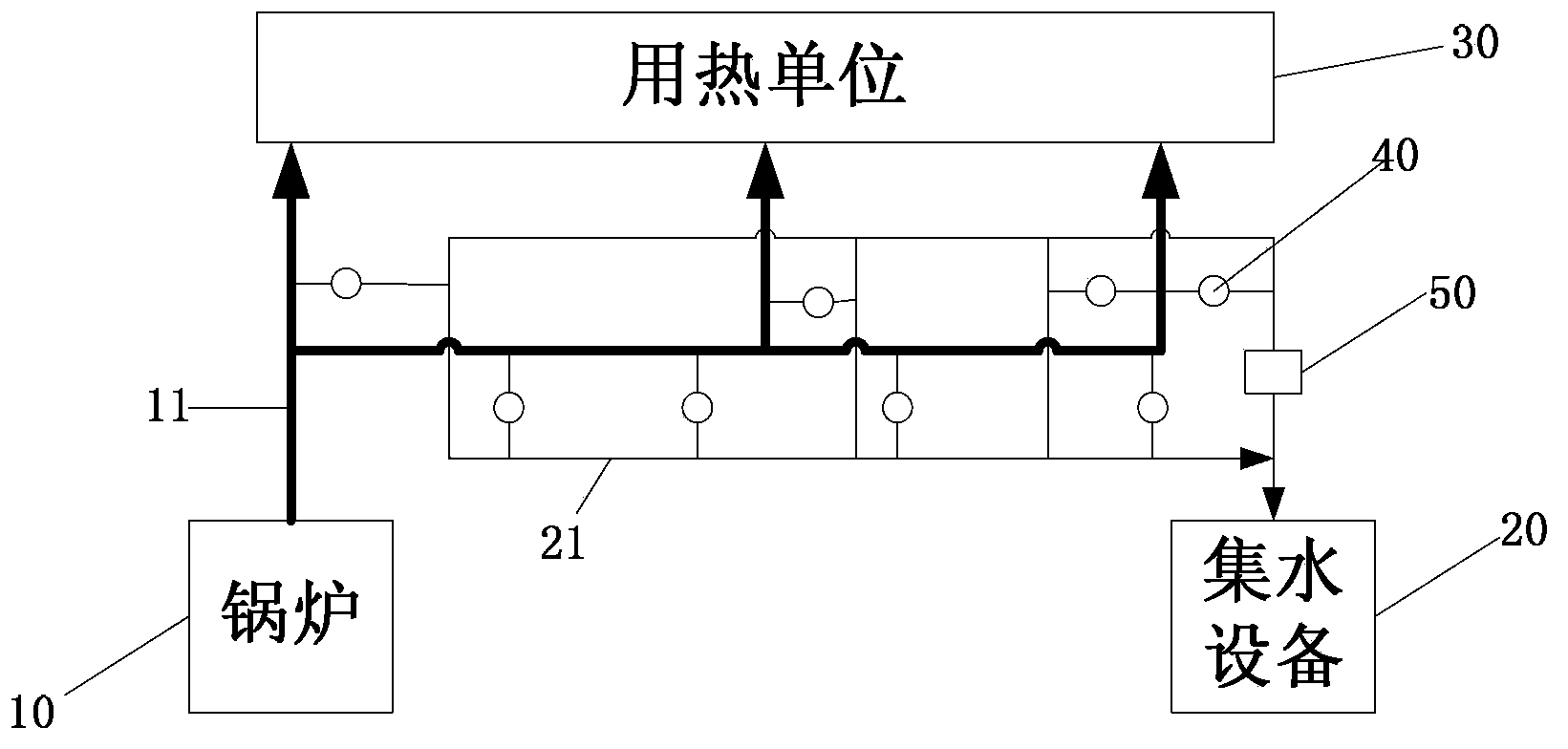

Condensate recovery system for steam heating supply system

A recovery system and steam heating technology, which is applied in the field of condensed water recovery system of steam heating system, can solve the problems of water flow accumulation, affecting the service life of pipelines, and unable to discharge in time, so as to achieve the effect of solving water flow accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The various embodiments of the present application will be described in detail below, and the drawings are used as examples. In addition to these detailed descriptions, the present invention can also be widely implemented in other embodiments, and any easy replacement, modification, and equivalent changes of any of the embodiments are included in the scope of this case, and the following patent scope is allow. In the description of the specification, many specific details are provided in order to enable readers to have a more complete understanding of the present invention; however, the present invention may still be practiced under the premise of omitting some or all of these specific details. Also, well-known steps or elements have not been described in detail in order to avoid unnecessarily limiting the invention. The same or similar components in the drawings will be represented by the same or similar symbols. It should be noted that the illustrations are for illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com