Gypsum-based steel structure fireproof protection material containing reinforced fibers

A technology of reinforcing fibers and protective materials, which is applied in the field of gypsum-based steel structure fire protection materials, can solve the problems of loose and rough surface, poor fire resistance, easy hollowing, etc., and achieves the effect of low price, improved overall fire resistance, and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

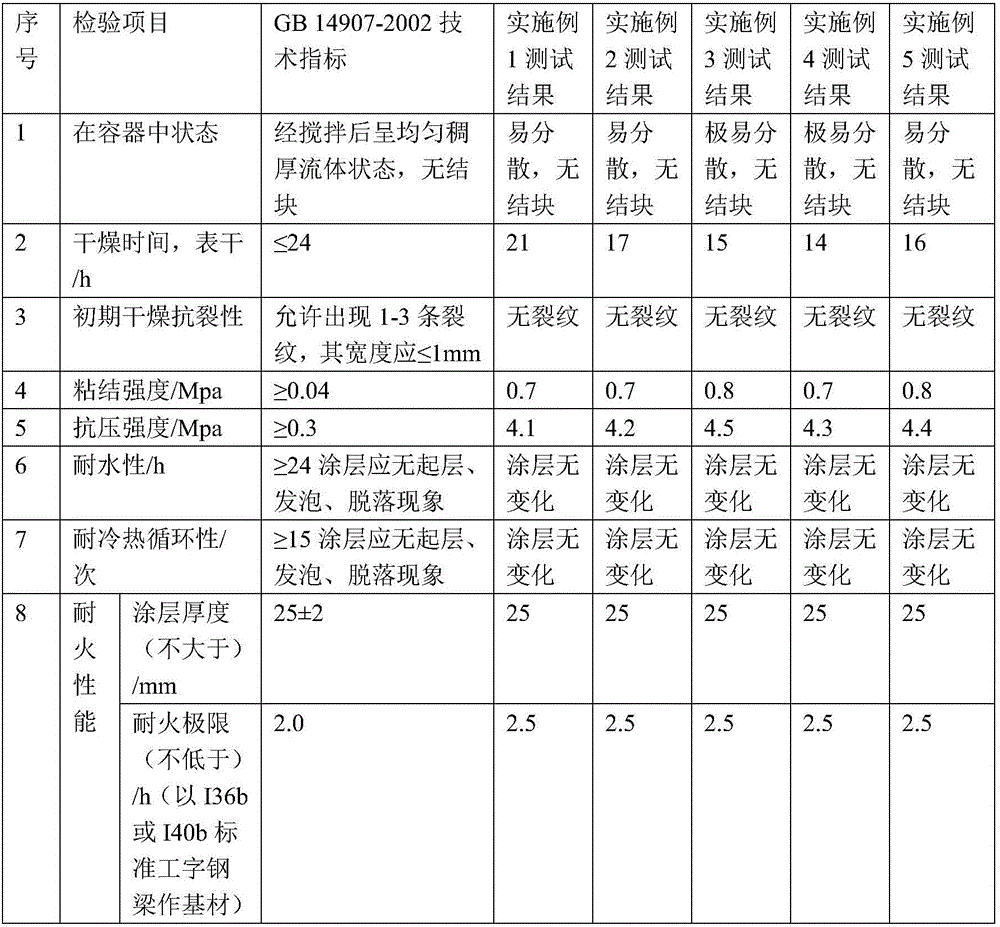

Examples

Embodiment 1

[0044] A gypsum-based steel structure fire protection material containing reinforced fibers, which is composed of the following components by weight: desulfurized gypsum provided by Shanxi Jinneng Power Group Co., Ltd. 82%, bulk density provided by Shanghai Qiangwei Thermal Insulation Material Co., Ltd. 120- 150kg / m 3 , the volumetric water absorption rate is less than 50%, the thermal conductivity is less than 0.05W / (m K) closed-cell expanded perlite 5%, the density provided by Shijiazhuang Chenxing Industrial Co., Ltd. is ≤100kg / m 3 , thermal conductivity less than 0.062W / (m·K), expanded vermiculite 10.5% with moisture content ≤3%, seafoam with fiber length of 3-8mm and diameter of 12-18μm provided by Hebei Hongli Sepiolite Wool Co., Ltd. 2% of stone fiber, 0.1% of water-retaining agent hydroxyethyl methyl cellulose ether (model EGC168) with a viscosity of 30000mPa s provided by Shin-Etsu Japan; redispersible latex powder vinyl acetate / ethylene tertiary carbonic acid copolym...

Embodiment 2

[0046] A gypsum-based steel structure fire protection material containing reinforced fibers, which is composed of the following components by weight: 94% desulfurized gypsum provided by Shanxi Jinneng Electric Power Group Co., Ltd., and the thickness provided by Lingshou County Tianze Mineral Products Processing Factory is 0.5-10μm, flake mica with a diameter of less than 0.2mm 3%, 0.5% aluminum silicate fiber with a length of 5-10mm and a diameter of 3-10μm provided by Hebei Jinghang Mining Products Co., Ltd., Changzhou Tianyi Engineering Fiber Co., Ltd. provides 0.5% of monofilament polypropylene fiber with a length of 6-9mm; Dow Chemical provides 0.5% of water-retaining agent hydroxyethyl methyl cellulose ether (model XCS47107) with a viscosity of 15000mPa s; Wacker Chemical Provided redispersible latex powder ethylene / vinyl acetate copolymer (model 5010N) 1%; retarder sodium tripolyphosphate 0.4%; air-entraining agent sodium alkylbenzene sulfonate 0.1%.

Embodiment 3

[0048] A gypsum-based steel structure fire protection material containing reinforced fibers, which is composed of the following components in weight ratio: 95% desulfurized gypsum provided by Shanxi Jinneng Electric Power Group Co., Ltd., surface vitrification provided by Xinyang Zhongsen Perlite Application Co., Ltd. The closed cell rate is above 90%, the volume water absorption rate is below 25%, and the bulk density is 80-120kg / m 3 3.5% of vitrified microbeads, 0.5% of glass fiber with a length of 1-5mm and a diameter of 10-15μm provided by Jiangsu Kangdafu New Material Technology Co., Ltd., and a water-retaining agent with a viscosity of 60000mPa·s provided by Hercules Temple Hydroxyethyl methyl cellulose ether 0.39% (model is BX165M); redispersible latex powder acrylic copolymer (model is LDM 7000P) 0.1% provided by Nippon Synthetic Chemicals; retarder sodium citrate 0.5%; air-entraining agent Sodium alkylaryl sulfonate 0.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com