Sewage treatment method for simultaneously removing phosphor and nitrogen in process of reinforcing autotrophic denitrification of sulfur

A technology for synchronous denitrification and phosphorus removal and sewage treatment, which is applied in the fields of special compound water treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of high calcium ion concentration in effluent and low utilization rate of carbon source , The effect of denitrification and phosphorus removal is difficult, etc., to achieve the effect of strengthening the denitrification effect, improving the utilization rate, and improving the phosphorus removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

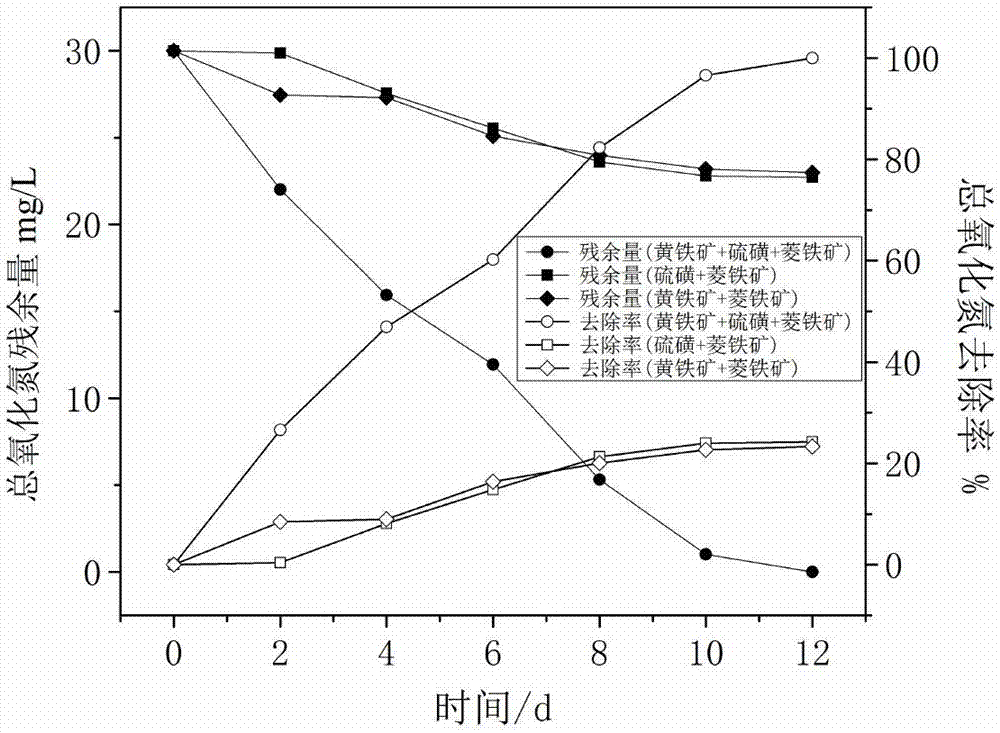

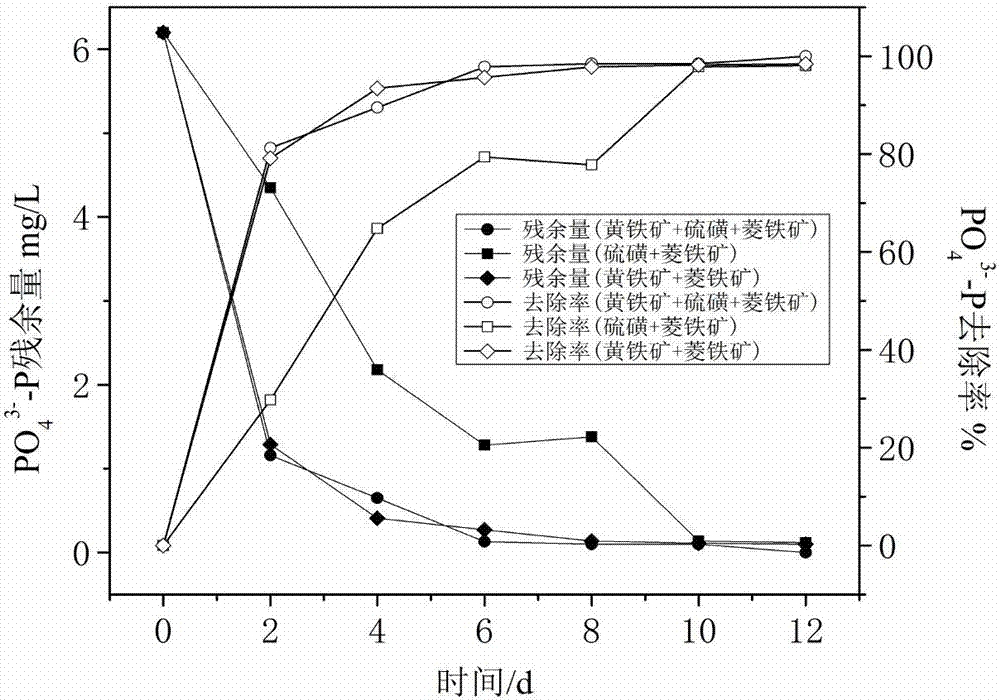

[0051] This embodiment is a combination of pyrite+sulfur+siderite.

[0052] Take 9g of pyrite particles to be used, 3g of sulfur particles and 3g of siderite particles and put them into the reaction container. In this embodiment, the mass ratio of pyrite, sulfur and siderite is 9:3:3.

[0053] Then add 50mL containing 30mg / L NO to the reaction vessel 3 - -N, 6.2mg / L PO 4 3- -P waste water.

[0054] Then add 3.5mL sulfur autotrophic denitrifying bacteria bacterium liquid (bacteria liquid volume accounts for 7% of waste water volume) in reaction vessel, blow off oxygen with nitrogen of above-mentioned mixed solution, then cover and seal and carry out denitrification reaction process, cultivate 12 days , respectively on the 2nd, 4th, 6th, 8th, 12th day 3 - -N, PO 4 3- -P concentration was detected.

Embodiment 2

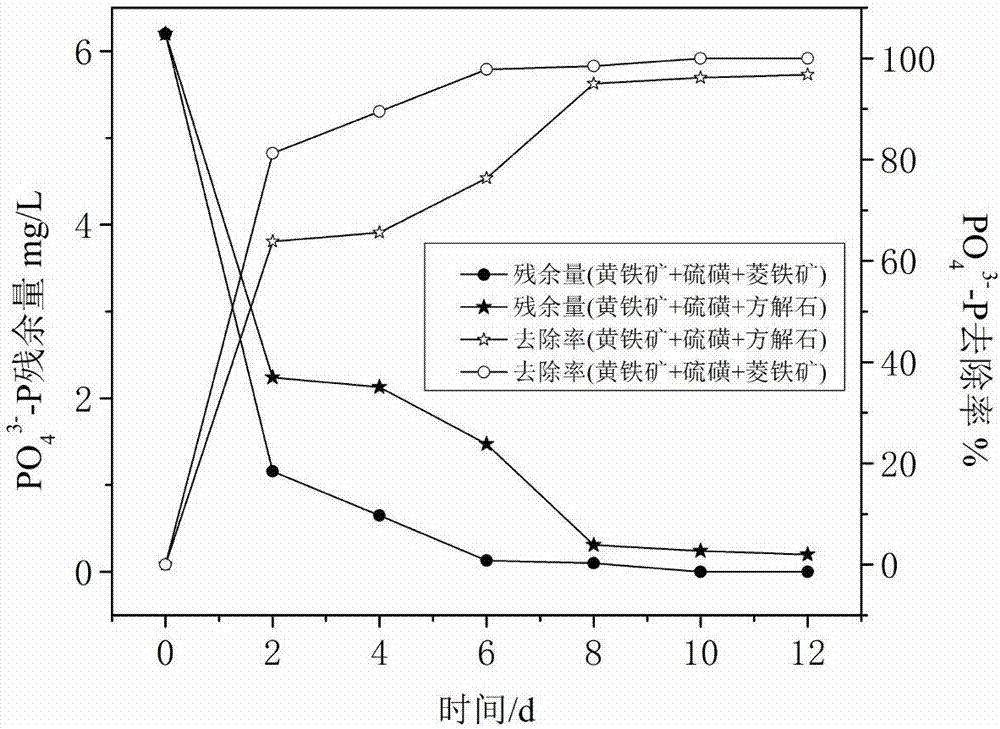

[0077] This implementation is the combination mode of pyrite+sulfur+siderite, and the preparation process of pyrite, sulfur and siderite is the same as that in embodiment 1.

[0078] Take 12g of pyrite particles, 3g of sulfur particles and 1g of siderite particles and put them into the reaction container. In this embodiment, the mass ratio of pyrite, sulfur and siderite is 12:3:1.

[0079] Then add 50mL containing 30mg / L NO to the reaction vessel 3 - -N, 6.2mg / L PO 4 3- -P waste water.

[0080] Then add 2.5mL sulfur autotrophic denitrifying bacteria bacterium liquid (bacteria liquid volume accounts for 5% of waste water volume) in reaction vessel, blow off oxygen with nitrogen of above-mentioned mixed solution, then cover and seal and carry out denitrification reaction process, cultivate 12 days , for NO in wastewater every day 3 - -N, PO 4 3- -P concentration was detected.

[0081] As a result, in the denitrification system, nitrogen was completely removed after 10 d...

Embodiment 3

[0083] This implementation is the combination mode of pyrite+sulfur+siderite, and the preparation process of pyrite, sulfur and siderite is the same as that in embodiment 1.

[0084]The preparation process of pyrite, sulfur and siderite in the present embodiment is the same as in embodiment 1.

[0085] Take 3g of pyrite particles, 3g of sulfur particles and 1g of siderite particles and put them into the reaction container. In this embodiment, the mass ratio of pyrite, sulfur and siderite is 3:3:1.

[0086] Then add 50mL containing 1mg / L NO to the reaction vessel 3 - -N, 3mg / L PO 4 3- -P waste water.

[0087] Then add 1 mL of sulfur autotrophic denitrifying bacteria liquid (the volume of the bacterial liquid accounts for 2% of the waste water volume) in the reaction vessel, blow the above-mentioned mixed solution with argon to remove oxygen, then cover and seal to carry out the denitrification reaction process, and cultivate for 7 days , for NO in wastewater every day 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com