Efficient scaling powder and preparing method thereof

A flux and high-efficiency technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems affecting the quality of electronic products, prone to leakage risks, low insulation resistance, etc., to achieve easy implementation, easy cleaning, and improved solderability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

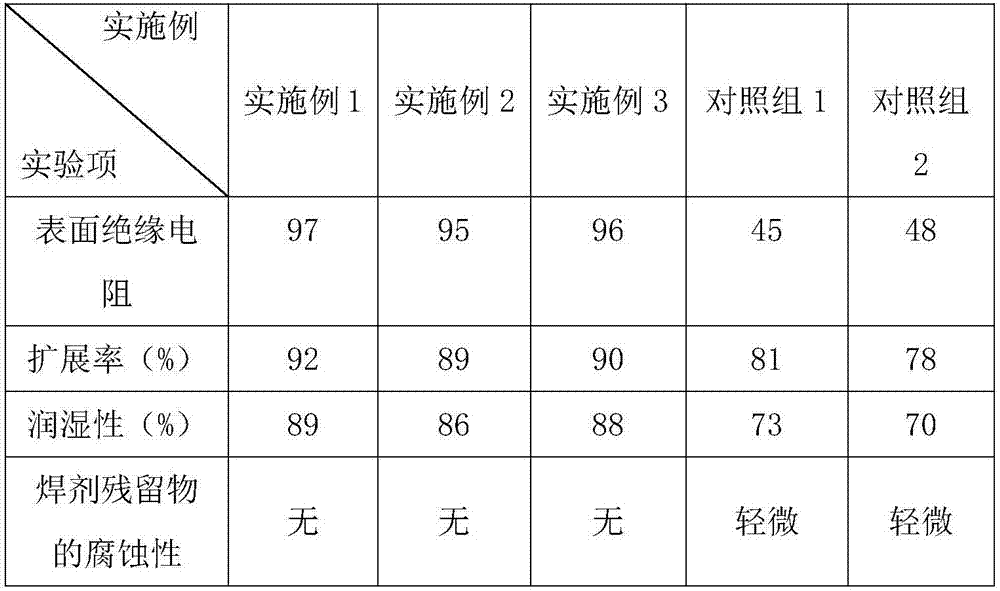

Examples

Embodiment 1

[0025] A high-efficiency soldering flux, which is made of the following raw materials in parts by weight: 7 parts of polyacrylic acid, 5 parts of succinic acid, 4 parts of epoxy octyl stearate, 3 parts of lauryl alcohol, modified 30 parts of rosin, 0.5 part of benzotriazole, 0.5 part of benzimidazole, 3 parts of acrylate, 0.4 part of acrylonitrile, 10 parts of benzyl alcohol, 4 parts of cyclohexanol, 40 parts of ethanol, 0.5 part of surfactant, 0.4 parts of oxidizing agent, 5 parts of nano silicon dioxide, 6 parts of nano titanium dioxide, 150 parts of deionized water.

[0026] Wherein, the surfactant is one of octylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, isooctylphenol polyoxyethylene ether, nonionic fluorosurfactant, perfluorooctylamide quaternary ammonium salt a mixture of two or more.

[0027] Wherein, the antioxidant is one or a mixture of two or more of phenolic compounds, modified cellulose, polyphenolic resin, acetal, polyether and polyol. ...

Embodiment 2

[0037] A high-efficiency soldering flux is characterized in that the high-efficiency soldering flux is made of the following raw materials in parts by weight: 4 parts of polyacrylic acid, 3 parts of succinic acid, 2 parts of epoxy octyl stearate, 1 part of lauryl alcohol 20 parts of modified rosin, 0.3 parts of benzotriazole, 0.2 parts of benzimidazole, 1 part of acrylate, 0.2 parts of acrylonitrile, 5 parts of benzyl alcohol, 2 parts of cyclohexanol, 30 parts of ethanol, surfactant 0.3 parts, 0.2 parts of antioxidant, 2 parts of nano silicon dioxide, 3 parts of nano titanium dioxide, 100 parts of deionized water.

[0038] Wherein, the surfactant is one of octylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, isooctylphenol polyoxyethylene ether, nonionic fluorosurfactant, perfluorooctylamide quaternary ammonium salt a mixture of two or more.

[0039] Wherein, the antioxidant is one or a mixture of two or more of phenolic compounds, modified cellulose, polyp...

Embodiment 3

[0049] A high-efficiency soldering flux is characterized in that the high-efficiency soldering flux is made of the following raw materials in parts by weight: 10 parts of polyacrylic acid, 8 parts of succinic acid, 6 parts of epoxy octyl stearate, 5 parts of lauryl alcohol 40 parts of modified rosin, 0.8 parts of benzotriazole, 0.8 part of benzimidazole, 5 parts of acrylate, 0.6 part of acrylonitrile, 15 parts of benzyl alcohol, 6 parts of cyclohexanol, 50 parts of ethanol, surfactant 0.8 parts, 0.6 parts of antioxidant, 8 parts of nano silicon dioxide, 10 parts of nano titanium dioxide, 200 parts of deionized water.

[0050] Wherein, the surfactant is one of octylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, isooctylphenol polyoxyethylene ether, nonionic fluorosurfactant, perfluorooctylamide quaternary ammonium salt a mixture of two or more.

[0051] Wherein, the antioxidant is one or a mixture of two or more of phenolic compounds, modified cellulose, poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com