Self-protection flux-cored wire for strengthening surface of large hot-forging die and production method of self-protection flux-cored wire

The technology of flux-cored wire and hot forging die is applied in the field of welding material manufacturing, which can solve the problems of wear, deformation, and short service life of large hot forging die, and achieve the effect of improving hardness and strength and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

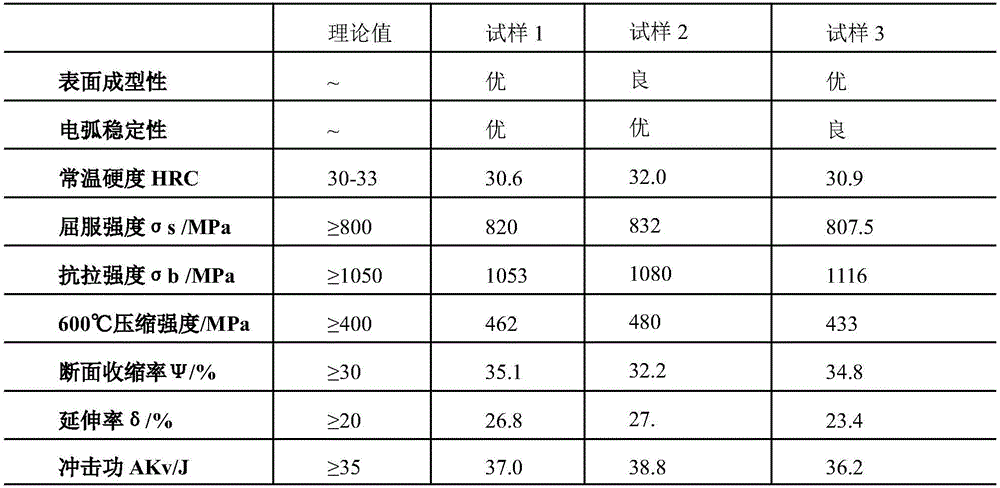

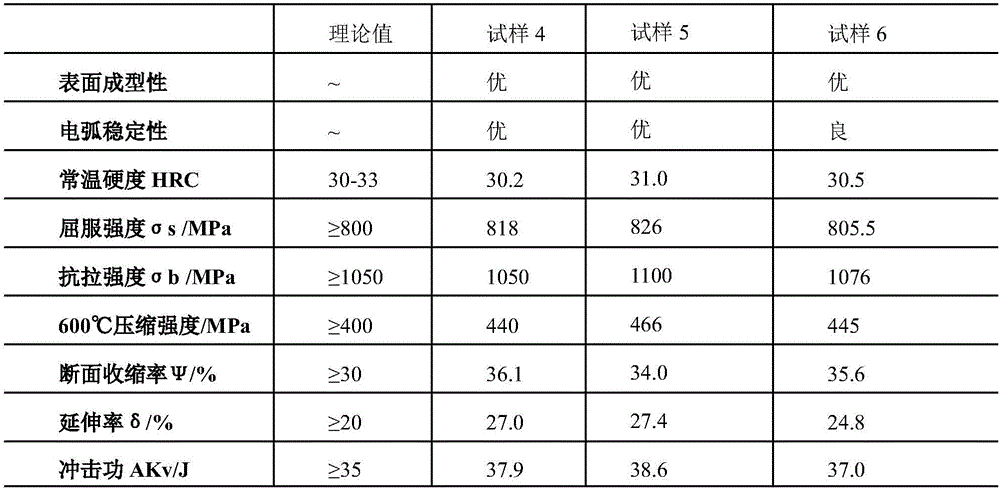

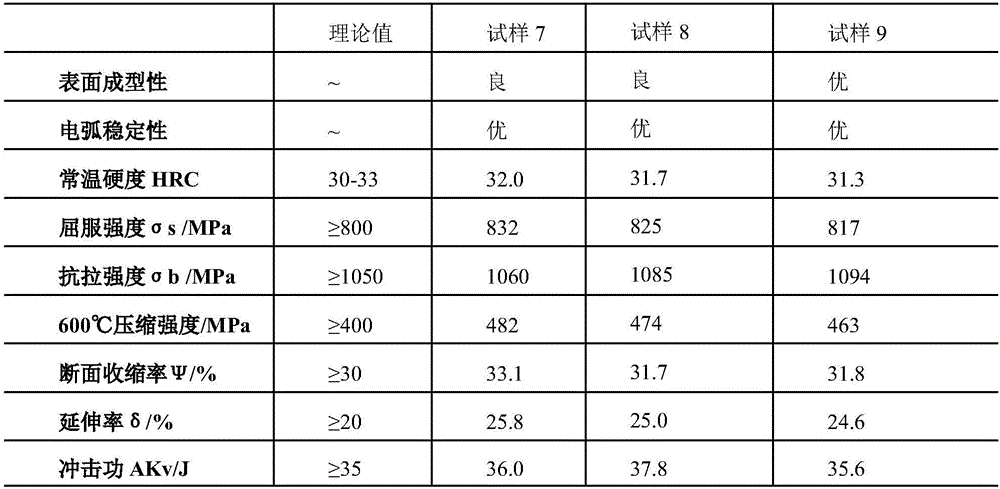

Embodiment 1

[0021] 1) Dry the raw materials chromium, molybdenum, tungsten, nickel, silicon, manganese, niobium, carbon, phosphorus, sulfur and cobalt at 120°C for 1 hour respectively, and use 80-mesh sieves to sieve the dried raw materials respectively, Preserve the sieved raw materials in an environment of 80°C for later use;

[0022]2) Weigh the raw materials of the drug core wire drug core according to the following proportions: chromium element content 28%, molybdenum element content 9%, tungsten element content 2.4%, nickel element content 2%, silicon element content 1%, manganese element content 0.8%, niobium element content 0.23%, carbon element content 1.4%, phosphorus element content 0.01%, sulfur element content 0.01%, and the balance is cobalt. Add the weighed raw materials into the mixer and mix for 2 hours to obtain the drug core powder ;

[0023] 3) Obtain the H08A steel strip for ultrasonic cleaning and drying, process the cross section of the H08A steel strip into a U-sh...

Embodiment 2

[0029] 1) Dry the raw materials chromium, molybdenum, tungsten, nickel, silicon, manganese, niobium, carbon, phosphorus, sulfur and cobalt at 120°C for 1 hour respectively, and use 80-mesh sieves to sieve the dried raw materials respectively, Preserve the sieved raw materials in an environment of 80°C for later use;

[0030] 2) Weigh the raw materials of the drug core wire drug core according to the following proportions: chromium element content 26%, molybdenum element content 8%, tungsten element content 1.8%, nickel element content 1.5%, silicon element content 0.8%, manganese element content 0.6%, niobium element content 0.15%, carbon element content 1.2%, phosphorus element content 0.01%, sulfur element content 0.01%, and the balance is cobalt. Add the weighed raw materials into the mixer and mix for 2 hours to obtain the drug core powder ;

[0031] 3) Obtain the H08A steel strip for ultrasonic cleaning and drying, process the cross section of the H08A steel strip into a...

Embodiment 3

[0037] 1) Dry the raw materials chromium, molybdenum, tungsten, nickel, silicon, manganese, niobium, carbon, phosphorus, sulfur and cobalt at 120°C for 1 hour respectively, and use 80-mesh sieves to sieve the dried raw materials respectively, Preserve the sieved raw materials in an environment of 80°C for later use;

[0038] 2) Weigh the raw materials of the drug core wire drug core according to the following proportions: chromium element content 30%, molybdenum element content 10%, tungsten element content 3%, nickel element content 2.5%, silicon element content 1.2%, manganese element content 1.0%, niobium element content 0.3%, carbon element content 1.6%, phosphorus element content 0.01%, sulfur element content 0.01%, and the balance is cobalt. Add the weighed raw materials into the mixer and mix for 2 hours to obtain the drug core powder ;

[0039] 3) Obtain the H08A steel strip for ultrasonic cleaning and drying, process the cross section of the H08A steel strip into a U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com