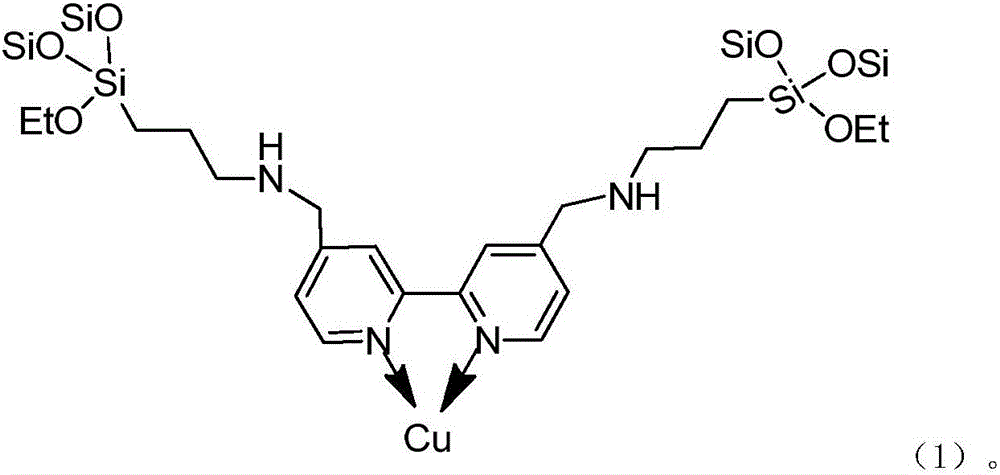

Silicon dioxide loaded copper-dipyridyl catalyst and its preparation method

A technology of silicon dioxide and bipyridine, applied in the field of copper-bipyridine catalyst and preparation thereof, can solve the problems of difficult separation and recovery, equipment corrosion, large feeding amount of organic ligands, etc., so as to overcome the problems of large feeding amount and easy separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1.000g of dry nano-silica (50nm diameter) and 1.105g of 3-aminopropyltriethoxysilane into 30mL of dry toluene, keep stirring and heating to 120°C under nitrogen protection, and reflux for 24h. After cooling, the reaction mixture was separated by filtration, and the filter cake was washed three times with 150 mL of toluene, and the solid was vacuum-dried at 50° C. for 3 h to obtain surface-aminated silica.

[0024] Heat 0.070g of 4-formaldehyde-2,2'-bipyridine and 1.000g of surface aminated silicon dioxide in 25mL of toluene solvent under the protection of nitrogen to 120°C and reflux for 20h. After cooling to room temperature, add 6mL of ethanol, 0.072g of sodium borohydride and 0.25mL of glacial acetic acid, and stir for 3 hours. The reaction mixture is separated by filtration, and the filter cake is washed with 100mL of water and ethanol several times in sequence. Dry under vacuum for 3 hours to obtain the surface-modified bipyridyl silica.

[0025] Dissolve 0.0...

Embodiment 2

[0027] Take 1.500g of dry nano-silica (50nm diameter) and 1.265g of 3-aminopropyltriethoxysilane into 30mL of dry toluene, keep stirring and heating to 120°C under nitrogen protection, and reflux for 24h. After cooling, the reaction mixture was separated by filtration, and the filter cake was washed three times with 200 mL of toluene, and the solid was vacuum-dried at 50° C. for 1 h to obtain surface-aminated silica.

[0028] Heat 0.070g of 4-formaldehyde-2,2'-bipyridine and 1.020g of surface aminated silicon dioxide in 30mL of toluene solvent under the protection of nitrogen to 122°C and reflux for 18h. After cooling to room temperature, add 6 mL of ethanol, 0.072 g of sodium borohydride and 0.25 mL of glacial acetic acid, stir for 4 h, filter and separate the reaction mixture, and wash the filter cake with 100 mL of water and ethanol several times in sequence, and place the solid at 50 °C After vacuum drying for 4 hours, the surface-modified bipyridyl silica was obtained.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com