A supported composite metal molecular sieve catalyst for catalyzing the coupling of methyl chloride to prepare low-carbon olefins

A technology for catalyzing methyl chloride and composite metals, applied in the field of supported composite metal molecular sieve catalysts, can solve the problems of reduced selectivity of low-carbon olefins, reduced Lewis acid content, reduced methyl chloride conversion rate, etc., so as to improve selectivity and prolong stability. Sexual, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

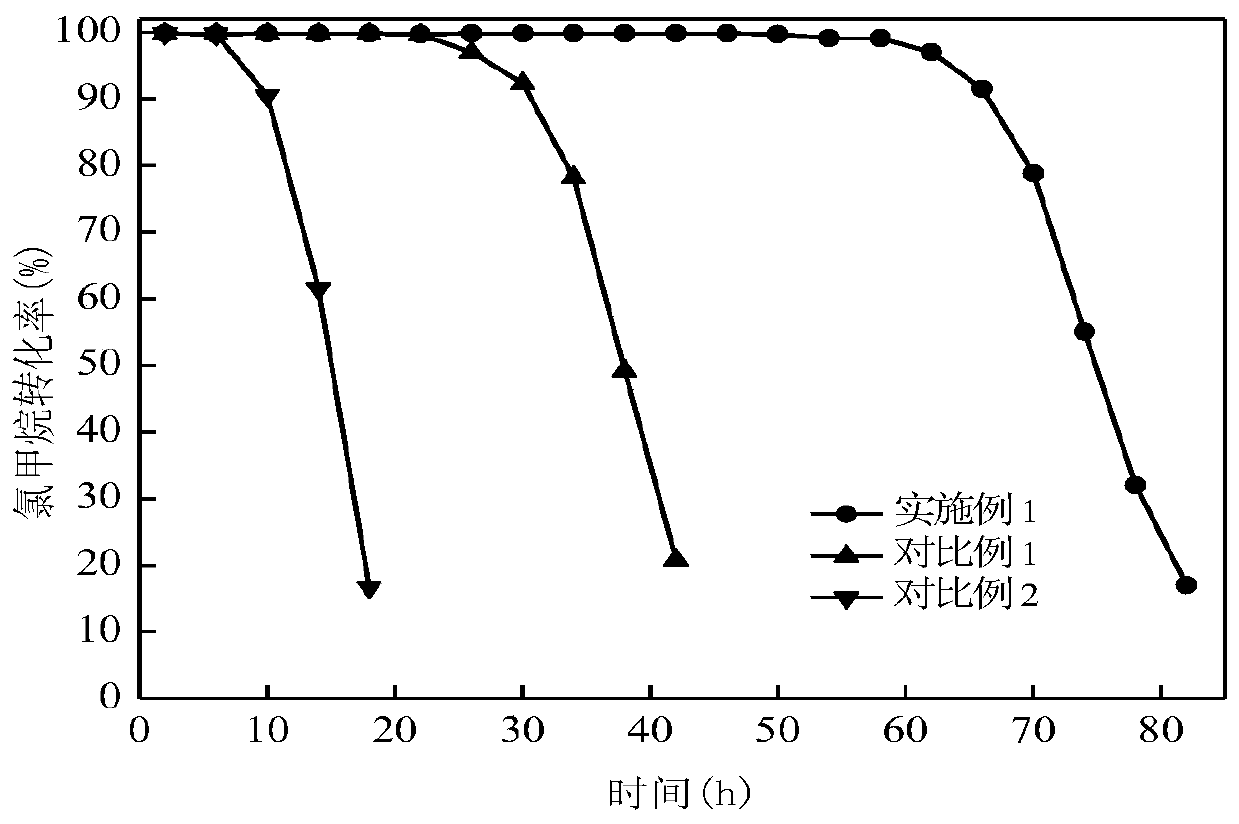

Embodiment 1

[0030] Get the HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =50), by gradually adding deionized water dropwise, the saturated water absorption rate of 10gHZSM-5 molecular sieve was measured to be 7.9mL.

[0031] 3.80g Ca(NO 3 ) 2 4H 2 O and 1.14g Mg(NO 3 ) 2 ·6H 2O was dissolved in 7.9mL deionized water to make nitrate aqueous solution, placed in a 50mL beaker, and under rapid stirring, 10g HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =50) into a beaker, mixed evenly, ultrasonically dissolved at 30°C for 1h, left at room temperature for 24h, then placed in an oven at 110°C for 24h; baked in a muffle furnace at 570°C for 3h, the obtained composite metal The mass percent content of the modified molecular sieve catalyst is Ca: 0.06, Mg: 0.01, and the rest is HZSM-5, named 6Ca-1Mg / HZSM-5.

[0032] The performance test of the catalyst was carried out in a glass reaction tube with a three-stage temperature-controlled fixed bed. The 6Ca-1Mg / HZSM-5 molecular sieve prepared by the abo...

Embodiment 2

[0034] Get the HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =25), by gradually adding deionized water dropwise, the saturated water absorption rate of 10gHZSM-5 molecular sieve was measured to be 7.0mL.

[0035] 3.17g Ca(NO 3 ) 2 4H 2 O and 0.56 g KNO 3 Dissolve in 7.0mL deionized water to make nitrate aqueous solution, place in a 50mL beaker, stir rapidly, mix 10g HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =25) into a beaker, after mixing evenly, ultrasonically dissolve at 50°C for 0.5h, then let it stand at room temperature for 30h, and then put it in an oven at 100°C to dry for 30h; The mass percent content of the metal-modified molecular sieve catalyst is Ca: 0.05, K: 0.02, and the rest is HZSM-5, which is named 5Ca-2K / HZSM-5.

[0036] The performance test of the catalyst was carried out in a glass reaction tube with a three-stage temperature-controlled fixed bed. The 5Ca-2K / HZSM-5 molecular sieve prepared by the above method was used to catalyze the preparation of light ...

Embodiment 3

[0038] Get the HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =80), by gradually adding deionized water dropwise, the saturated water absorption of 10gHZSM-5 molecular sieve was measured to be 8.9mL.

[0039] 3.17g Ca(NO 3 ) 2 4H 2 O and 2.27g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 8.9mL deionized water to make nitrate aqueous solution and placed in a 50mL beaker, and under rapid stirring, 10g HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =80) into a beaker, mixed evenly, ultrasonically dissolved at 40°C for 1h, left to stand at room temperature for 20h, then placed in an oven at 130°C for 20h; baked in a muffle furnace at 600°C for 3h, the obtained composite metal The mass percent content of the modified molecular sieve catalyst is Ca: 0.05, Mg: 0.02, and the rest is HZSM-5, which is named 5Ca-2Mg / HZSM-5.

[0040] The performance test of the catalyst was carried out in a glass reaction tube with a three-stage temperature-controlled fixed bed. The 5Ca-2Mg / HZSM-5 molecular sieve pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com