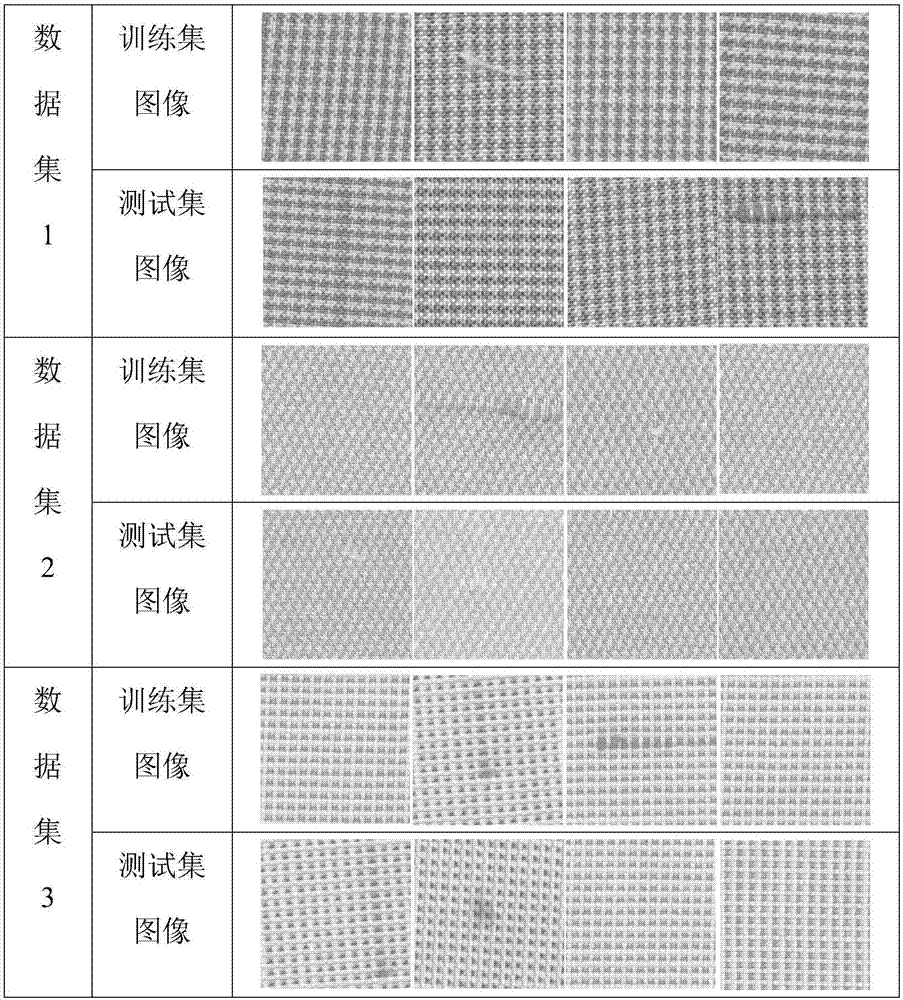

Convolutional neural network-based yarn dyed fabric defect detection method

A technology of convolutional neural network and detection method, which is applied in the field of color-dyed fabric defect detection based on convolutional neural network, can solve the problems of consuming manpower and material resources, low detection efficiency, and being easily affected by subjective factors, achieving high accuracy, The effect of fast defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

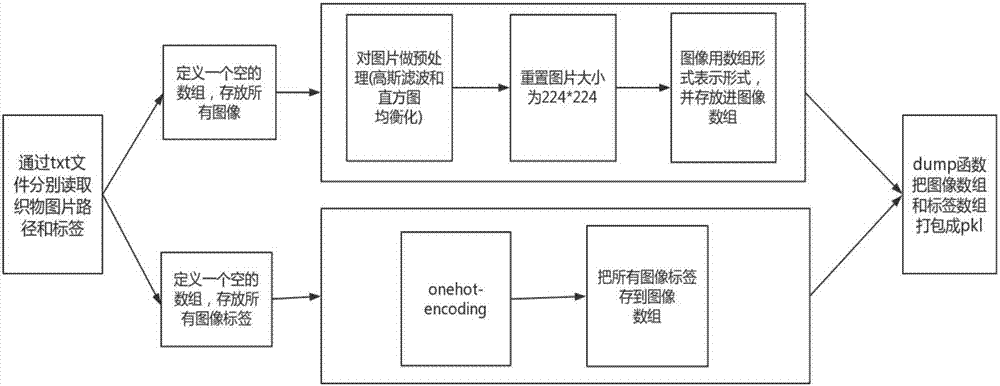

Method used

Image

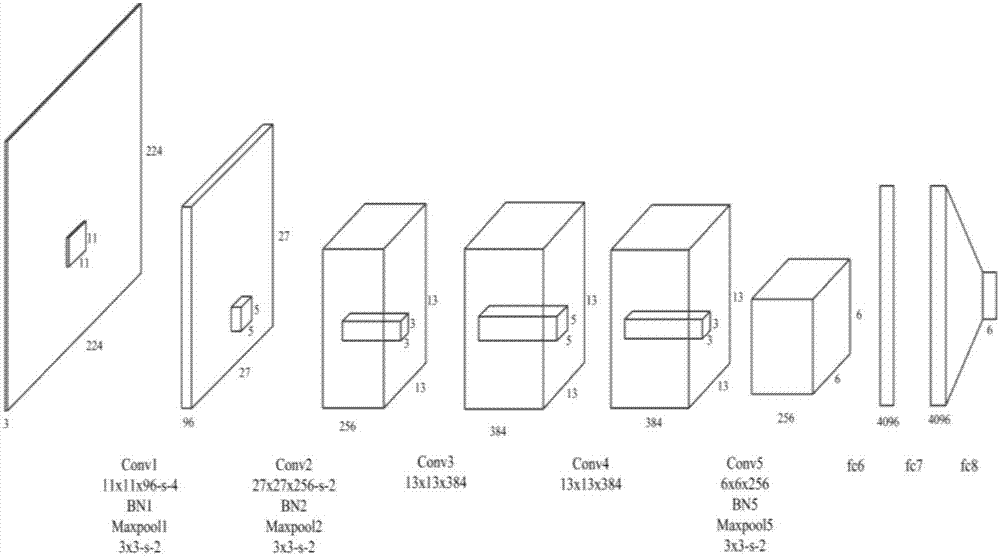

Examples

Embodiment Construction

[0046] The present invention will be further explained below in conjunction with the drawings:

[0047] Some terms in the present invention are explained as follows:

[0048] Number of network layers: Convolutional neural network extracts image features through convolution operations. The first convolutional layer extracts detailed features of the image edges. As the number of convolutional layers increases, the features continue to merge and can be extracted To obtain the overall feature map of the image, the more convolutional layers, the more accurate and comprehensive the learned image features. But it is not that the more convolutional layers, the better. The increase in the number of network layers will increase the amount of computer calculations and slow down the efficiency of the program. In addition, the convolutional neural network also contains a pooling layer, a fully connected layer and a dropout layer. The pooling layer is used to reduce the amount of data effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com