A dual-station liquid crystal panel off-line detection system and method

A liquid crystal panel, offline detection technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as low efficiency, achieve high practicability, high precision, and improve equipment productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and examples. Obviously, the examples are only some examples of the present invention, not all examples, so the examples should not be construed as limiting the present invention.

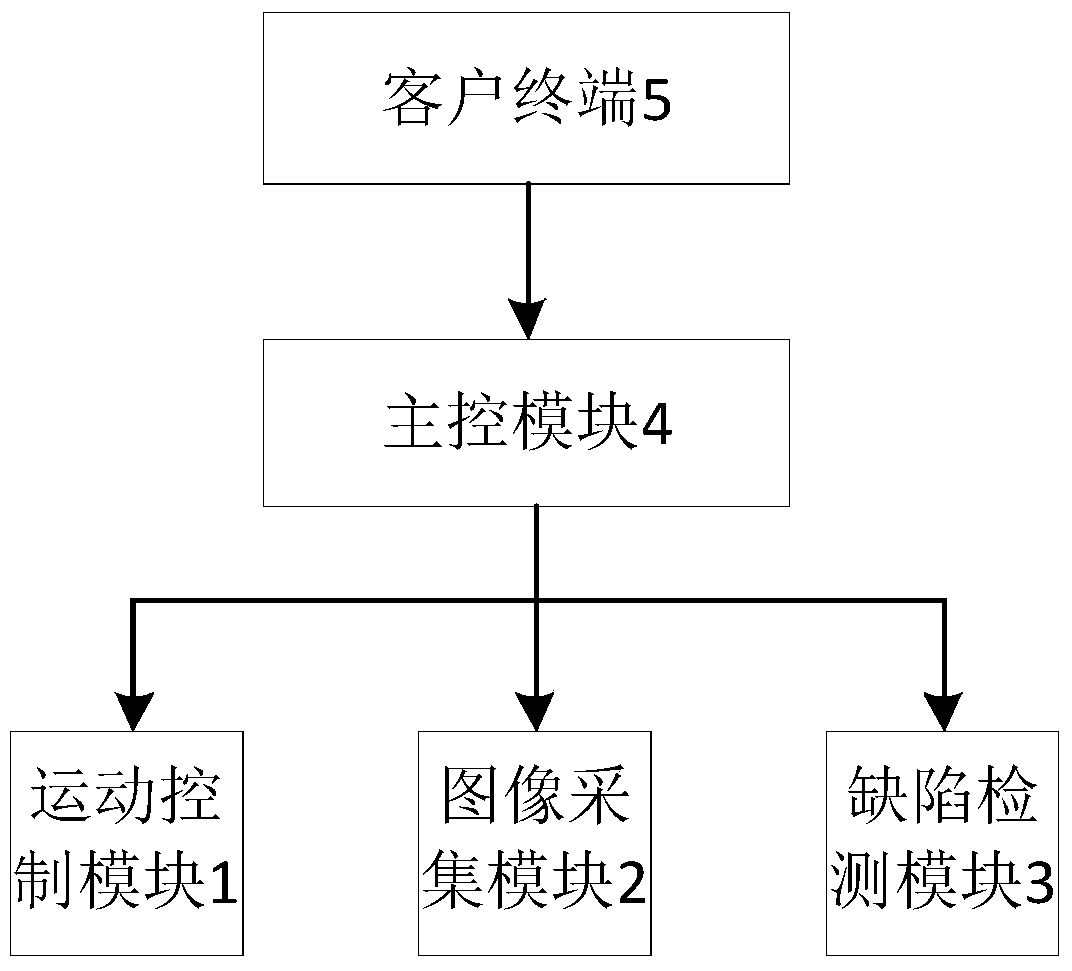

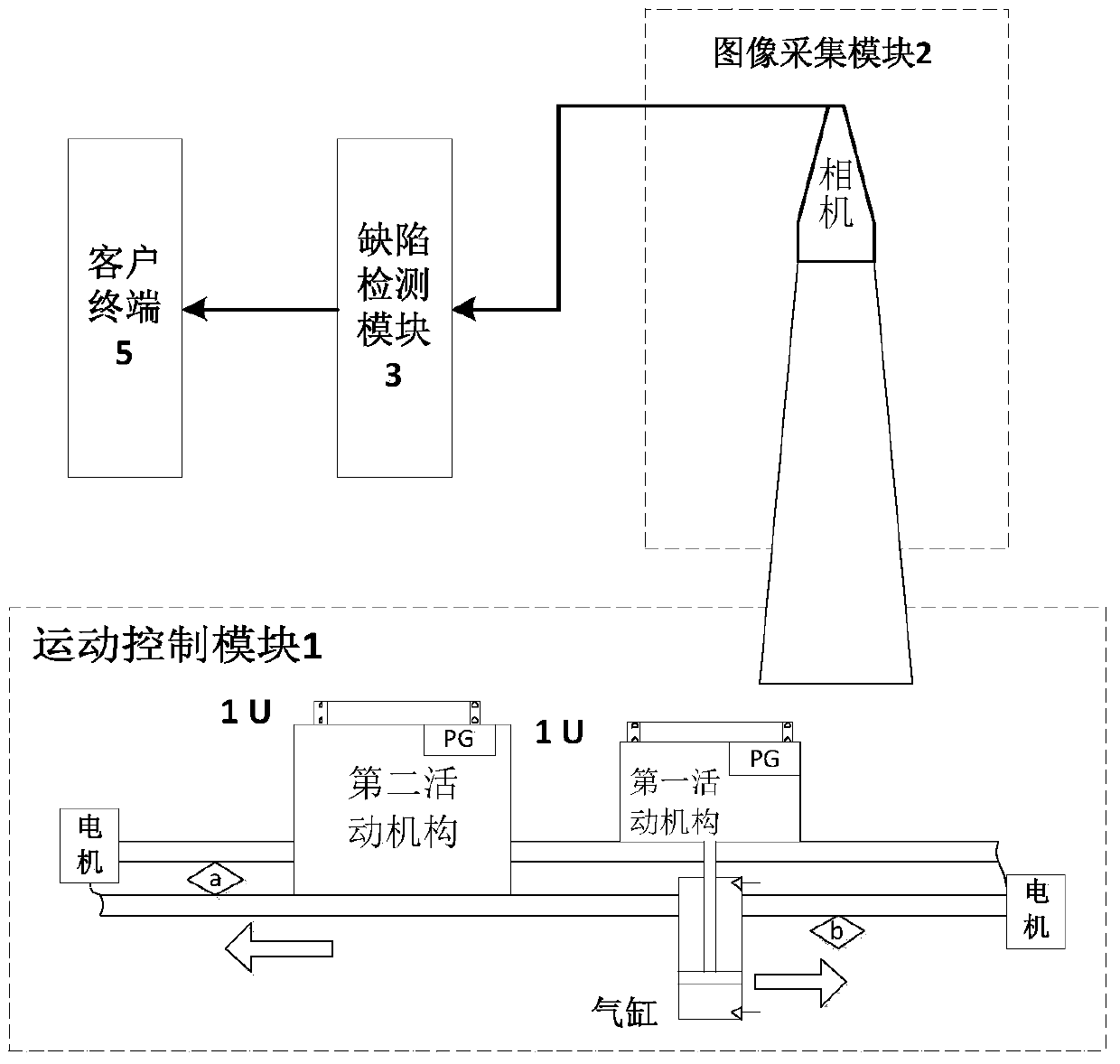

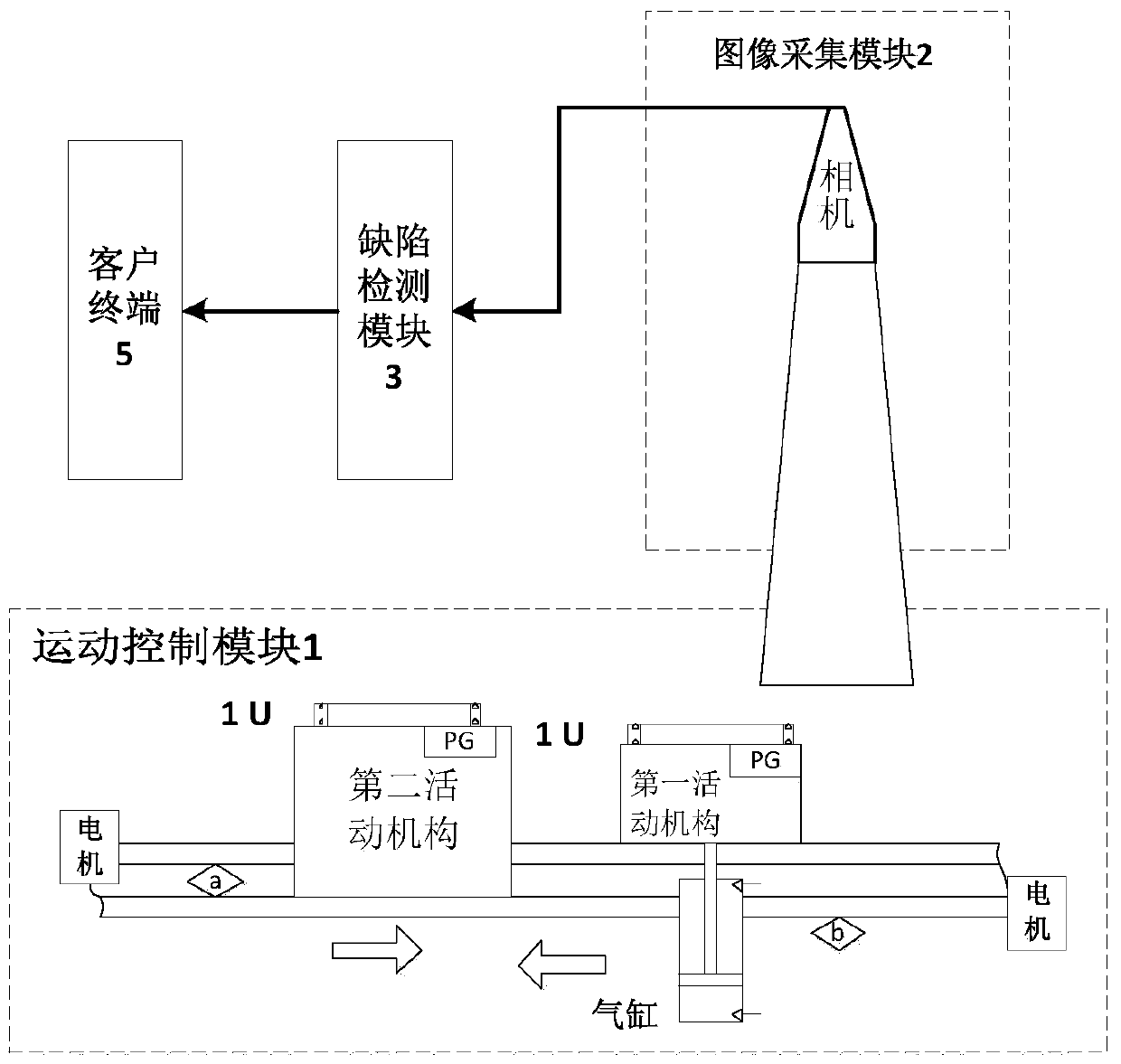

[0024] Such as figure 1 As shown, the present invention includes a motion control module 1 , an image acquisition module 2 , a defect detection module 3 , a main control module 4 and a client terminal 5 . The motion control module 1 includes a first motion unit and a second motion unit, the first motion unit and the second motion unit are used to carry the liquid crystal panel to be detected, and the two motion units can switch positions cyclically under the control of the main control module 4, Realize double-station real-time cycle detection. The main control module 4 is used to control the operation of the motion control module 1 , the image acquisition module 2 , and the defect detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com