Centrifugal compressor applied by delayed coking process

A centrifugal compressor and process application technology, which is applied in the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. Possibility of safety accident, effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1100

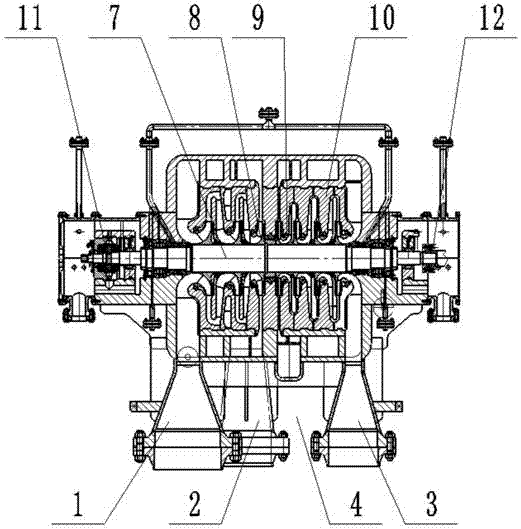

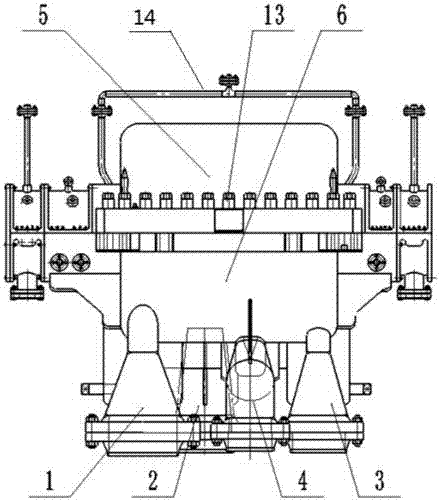

[0026] Example 1 Centrifugal compressor for delayed coking unit with 1 million tons / year

[0027] This embodiment is a seven-stage centrifugal compressor. The impeller adopts a closed impeller, and its blades adopt a back-curved structure. The rotor adopts seven impellers with an outer diameter of 450mm arranged back to back, three impellers in the high-pressure section, and four in the low-pressure section. impeller. And install a balance air pipe between the high pressure section and the low pressure section.

Embodiment 2

[0028] Example 2 Centrifugal compressor for delayed coking unit with 1 million tons / year

[0029] This embodiment is an eight-stage centrifugal compressor. The impeller adopts a closed impeller, and its blades adopt a back-curved structure. The rotor adopts eight impellers with an outer diameter of 450mm arranged back to back, four impellers in the high-pressure section, and four in the low-pressure section. impeller. And install a balance air pipe between the high pressure section and the low pressure section.

Embodiment 3140

[0030] Example 3 1.4 million tons / year centrifugal compressor for delayed coking unit

[0031] This embodiment is a seven-stage centrifugal compressor. The impeller adopts a closed impeller, and its blades adopt a back-curved structure. The rotor adopts seven impellers with an outer diameter of 450mm arranged back to back, three impellers in the high-pressure section, and four in the low-pressure section. impeller. And install a balance air pipe between the high pressure section and the low pressure section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com