Ultrasound thermal bonding high-density polyethylene composite fiber bundle for wiping and producing method thereof

A technology of high-density polyethylene and composite fibers, which is applied in fiber processing, filament generation, and bundling of newly extruded filaments, and can solve problems such as high cost, high decontamination rate, and low void rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

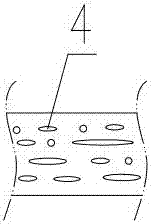

[0028] like figure 1 and figure 2 As shown, the present invention discloses a high-density polyethylene composite fiber tow for ultrasonic thermal bonding and wiping, which is composed of at least 100 composite fibers, and the cross-sectional structure of a single composite fiber is isotactic polypropylene or polyester. The core, the high-density polyethylene is the cladding on the outer surface of the core, the cladding is provided with grooves on the outer surface of the high-density polyethylene, and the cladding is that the outer surface of the high-density polyethylene is covered with an oil layer, and the oil layer is Surface active oil agent and antistatic oil agent, the diameter of the above-mentioned composite fiber is 0.1-100 microns, the length is 0.01-1,000,000 meters, the breaking strength is not less than 2.5cN / dtex, the elongation at break is 45-100%, and the number of crimps 0-50 pieces / 25mm, crimp rate 0-30%, oil content 0.001-1.8% by weight; the tow compose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com