Preparation method of waterproof monofilament fishing net binder

A technology for adhesives and fishing nets, applied in the types of adhesives, starch-derived adhesives, etc., can solve the problems of reducing the transparency of monofilament fishing nets, unable to bond nylon nodules, reducing the quality of monofilament fishing nets, etc. Low price, avoids starch residues, and has the effect of strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

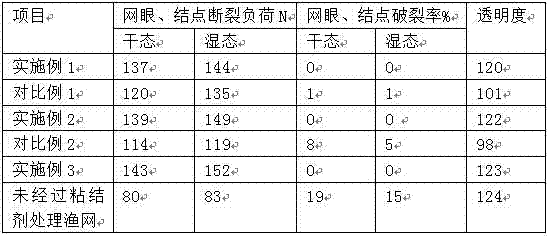

Examples

Embodiment 1

[0018] A preparation method for a waterproof monofilament fishing net adhesive, comprising the following steps:

[0019] (1) Put the starch in an oven at 60°C and bake for 20 minutes;

[0020] (2) Add N-octyldiaminoethylglycine hydrochloride to the starch, mix and stir evenly;

[0021] (3) After adding the additive solution to the mixture prepared in step (2), slowly add a strong oxidizing agent solution to it, raise the temperature of the reactant to 60°C, and heat it for 15 minutes, then filter to obtain the filter residue, and use the filter residue to After cleaning with deionized water, the required binder is obtained, wherein the additive liquid is made of the following components by weight: 11 parts of 2-keto-3-deoxyoctanoic acid ammonium, 20 parts of hydrochloric acid, 4 parts of hydroxyphosphoroacetic acid , 140 parts of water.

[0022] Specifically, the mass ratio of N-octyldiaminoethylglycine hydrochloride to starch is 1:95.

[0023] Specifically, the volume-to-m...

Embodiment 2

[0028] A preparation method for a waterproof monofilament fishing net adhesive, comprising the following steps:

[0029] (1) Put the starch in an oven at 65°C and bake for 25 minutes;

[0030] (2) Add N-octyldiaminoethylglycine hydrochloride to the starch, mix and stir evenly;

[0031] (3) After adding the additive solution to the mixture prepared in step (2), slowly add a strong oxidizing agent solution to it, raise the temperature of the reactant to 65°C, and heat it for 20 minutes, then filter to obtain the filter residue, and use the filter residue to After cleaning with deionized water, the required binder is obtained, wherein the additive solution is made of the following components by weight: 13 parts of 2-keto-3-deoxyoctanoic acid ammonium, 23 parts of hydrochloric acid, 6 parts of hydroxyphosphoroacetic acid , 150 parts of water.

[0032] Specifically, the mass ratio of N-octyldiaminoethylglycine hydrochloride to starch is 1:100.

[0033] Specifically, the volume-t...

Embodiment 3

[0038] A preparation method for a waterproof monofilament fishing net adhesive, comprising the following steps:

[0039] (1) Put the starch in an oven at 70°C and bake for 30 minutes;

[0040] (2) Add N-octyldiaminoethylglycine hydrochloride to the starch, mix and stir evenly;

[0041] (3) After adding the additive solution to the mixture prepared in step (2), slowly add a strong oxidizing agent solution to it, raise the temperature of the reactant to 70°C, and heat it for 30 minutes, then filter to obtain the filter residue, and use the filter residue to After cleaning with deionized water, the required binder is obtained, wherein the additive solution is made of the following components by weight: 15 parts of 2-keto-3-deoxyoctanoic acid ammonium, 25 parts of hydrochloric acid, 8 parts of hydroxyphosphoroacetic acid , 160 parts of water.

[0042] Specifically, the mass ratio of the above-mentioned N-octyldiaminoethylglycine hydrochloride to starch is 1:105.

[0043] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com