Direct injection molding chemical micro-foaming polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of direct injection molding chemical micro-foamed polypropylene composite materials and its preparation, can solve the molecular chain entanglement of ultra-high molar mass polyethylene, and the inability of polypropylene molecular weight to enter the PE chain segment, limit industrial application and other issues, to achieve the effect of small cells, reduce merger and rupture, and prevent carbon dioxide from escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

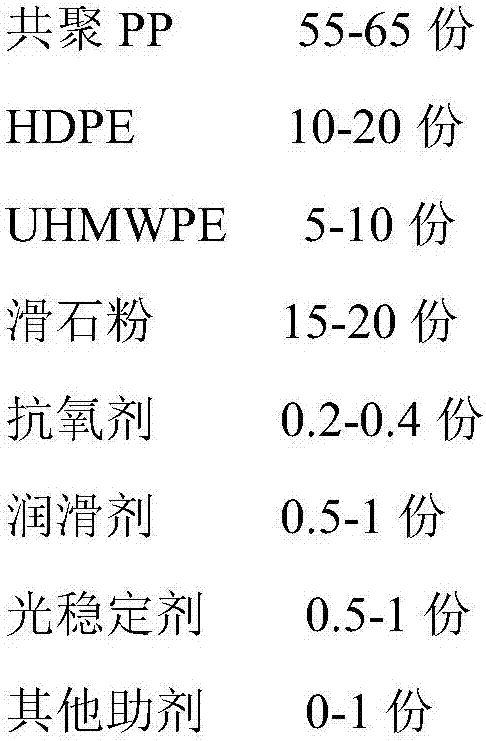

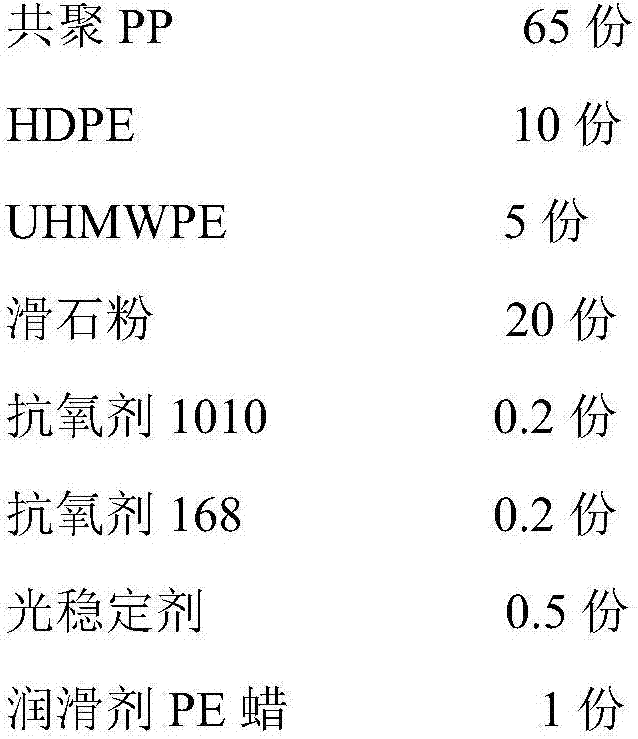

[0025] A kind of direct injection molding chemical micro-foaming polypropylene composite material in this embodiment is composed of the following raw materials in parts by weight:

[0026]

[0027] Concrete preparation method comprises the following steps:

[0028] (1) 65 parts of copolymerized PP, 10 parts of HDPE, 5 parts of UHMWPE, 20 parts of talcum powder, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, 0.5 parts of light stabilizer, and 1 part of lubricant PE wax were mixed at high speed Stir evenly in the mixer, then put it into the co-rotating twin-screw extruder, melt and extrude, and granulate to obtain a polypropylene composite material; the extrusion temperature of the extruder is 230-250 ° C, the screw speed It is 350-400r / min, and the vacuum degree is -0.06—-0.08MPa.

[0029] (2) After mixing 99wt% polypropylene composite material and 1wt% sodium bicarbonate foaming agent evenly, adopt the secondary mold opening process for injection foaming to o...

Embodiment 2

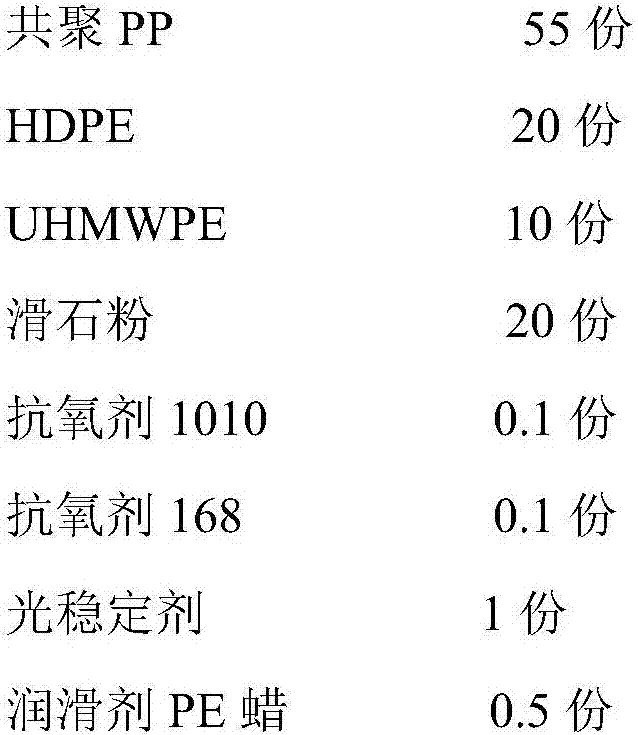

[0031] A kind of direct injection molding chemical micro-foaming polypropylene composite material in this embodiment is composed of the following raw materials in parts by weight:

[0032]

[0033] Concrete preparation method comprises the following steps:

[0034] (1) 55 parts of copolymerized PP, 20 parts of HDPE, 10 parts of UHMWPE, 20 parts of talcum powder, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 1 part of light stabilizer, and 0.5 parts of lubricant PE wax were mixed at high speed Stir evenly in the mixer, then put it into the co-rotating twin-screw extruder, melt and extrude, and granulate to obtain a polypropylene composite material; the extrusion temperature of the extruder is 230-250 ° C, the screw speed It is 350-400r / min, and the vacuum degree is -0.06—-0.08MPa.

[0035] (2) After mixing 97wt% polypropylene composite material and 3wt% sodium bicarbonate foaming agent evenly, adopt the secondary mold opening process for injection foaming to ob...

Embodiment 3

[0037] A kind of direct injection molding chemical micro-foaming polypropylene composite material in this embodiment is composed of the following raw materials in parts by weight:

[0038]

[0039]

[0040] Concrete preparation method comprises the following steps:

[0041](1) 60 parts of copolymerized PP, 20 parts of HDPE, 5 parts of UHMWPE, 15 parts of talcum powder, 0.15 parts of antioxidant 1010, 0.15 parts of antioxidant 168, 0.5 parts of light stabilizer, and 0.75 parts of lubricant PE wax were mixed at high speed Stir evenly in the mixer, then put it into the co-rotating twin-screw extruder, melt and extrude, and granulate to obtain a polypropylene composite material; the extrusion temperature of the extruder is 230-250 ° C, the screw speed It is 350-400r / min, and the vacuum degree is -0.06—-0.08MPa.

[0042] (2) After a kind of direct injection molding chemical micro-foaming polypropylene composite material and 3wt% sodium bicarbonate foaming agent are mixed uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com