Sea sand desalination-based processing process

A treatment process and sea sand technology, applied in the field of sea sand desalination treatment process, can solve the problems of high cost, increased operation cost, rising transportation cost, etc., and achieve the effect of reducing land occupation area, improving utilization rate, and reducing land pollution discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

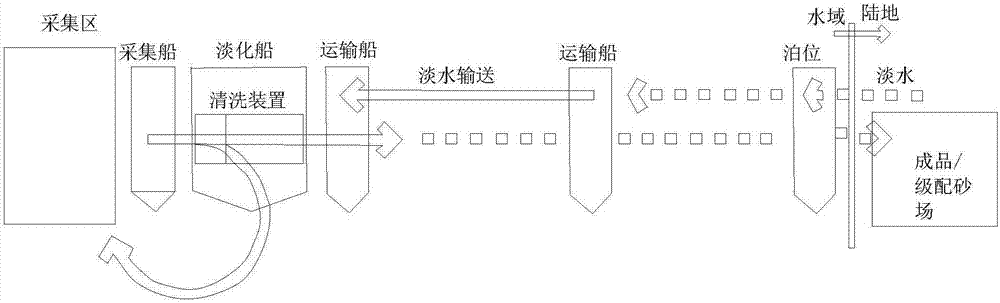

[0050] Such as figure 1 As shown, the treatment process for sea sand desalination includes the following steps:

[0051] (1) Sea sand collection ships collect sea sand in the sea collection area;

[0052] (2) After collecting the sea sand, transport the sea sand to the sea desalination ship;

[0053] (3) The transport ship transports fresh water to the desalination device of the offshore desalination ship to desalinate the sea sand;

[0054] (4) After the desalination treatment, it will be transported to the land sea sand finished product storage area by a transport ship.

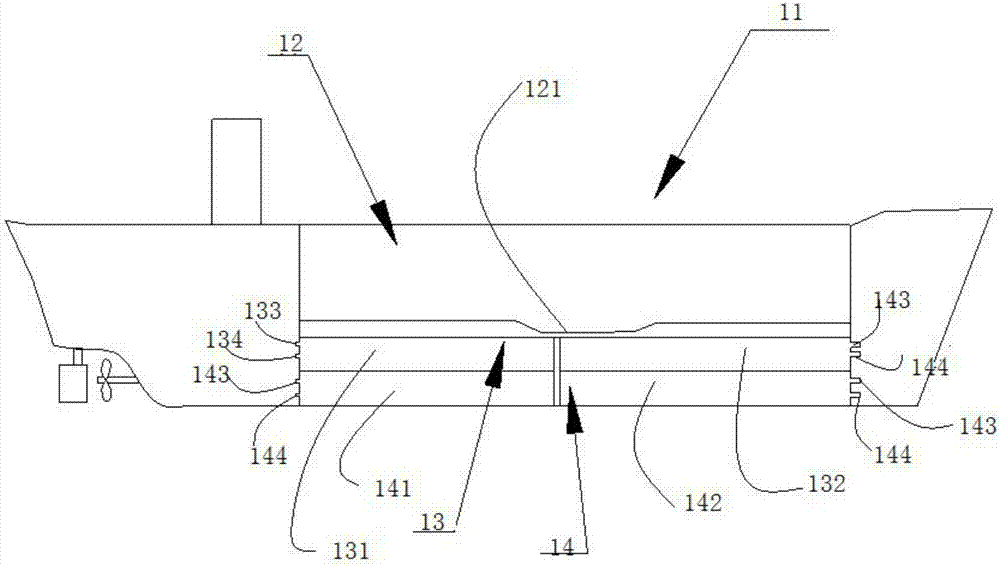

[0055] The transport ship in step 2 is implemented with the following structure, such as figure 2 As shown, it includes a sand tank 12 arranged on the main hull 11 and a bilge below the sand tank 12. The sand tank 12 is used to store sea sand and fresh water. The sand tank 12 is provided with a sand tank 121, preferably arranged in the center , the bottom of the sand tank 121 is provided with a vibration...

Embodiment 2

[0083] The treatment process for desalinating sea sand includes the following steps:

[0084] (1) Sea sand collection ships collect sea sand in the sea collection area;

[0085] (2) After collecting the sea sand, transport the sea sand to the sea desalination ship;

[0086] (3) The transport ship transports fresh water to the desalination device of the offshore desalination ship to desalinate the sea sand;

[0087] (4) After the desalination treatment, it will be transported to the land sea sand finished product storage area by a transport ship.

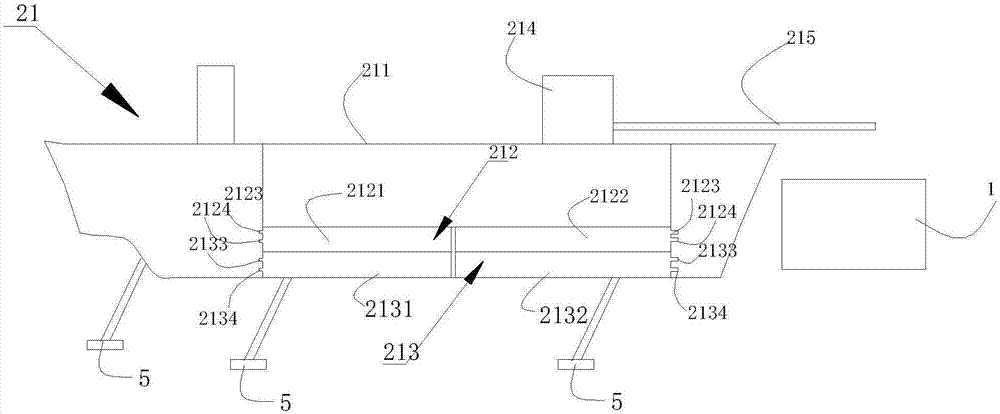

[0088] The hull structure of the transport ship and the desalination ship in the step is the same as that of the first embodiment. The process of desalination on the desalination ship is carried out through the sediment separation device and the vibration screening device, and the sea sand after screening is washed. The device is cleaned, and then the sea sand is transported to the transport ship.

[0089] The vibratory screening ...

Embodiment 3

[0093] The treatment process for desalinating sea sand includes the following steps:

[0094] (1) Sea sand collection ships collect sea sand in the sea collection area;

[0095] (2) After collecting the sea sand, transport the sea sand to the sea desalination ship;

[0096] (3) The transport ship transports fresh water to the desalination device of the offshore desalination ship to desalinate the sea sand;

[0097] (4) After the desalination treatment, it will be transported to the land sea sand finished product storage area by a transport ship.

[0098] The transport ship in the step is the same as the first embodiment. The desalination process on the desalination ship is cleaned by a sediment separation device, a cleaning device, and screened by a vibrating screening device. The screened sea sand is transported to the transport ship.

[0099] The cleaning device adopts a fluidized backwashing machine, including a rotating part 4001, a motor 4002, several connecting bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com