A line type filter cloth oven

An assembly line filter cloth technology, applied in the direction of electronic reversing motor control, control system, household appliances, etc., can solve the problems of large floor area, high energy consumption, affecting the drying efficiency of filter cloth, etc., and achieve a small contact area , Improve the drying efficiency and extend the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

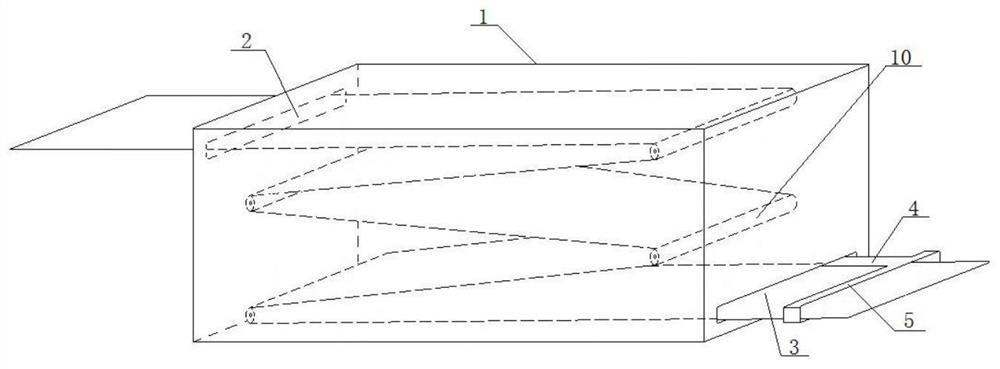

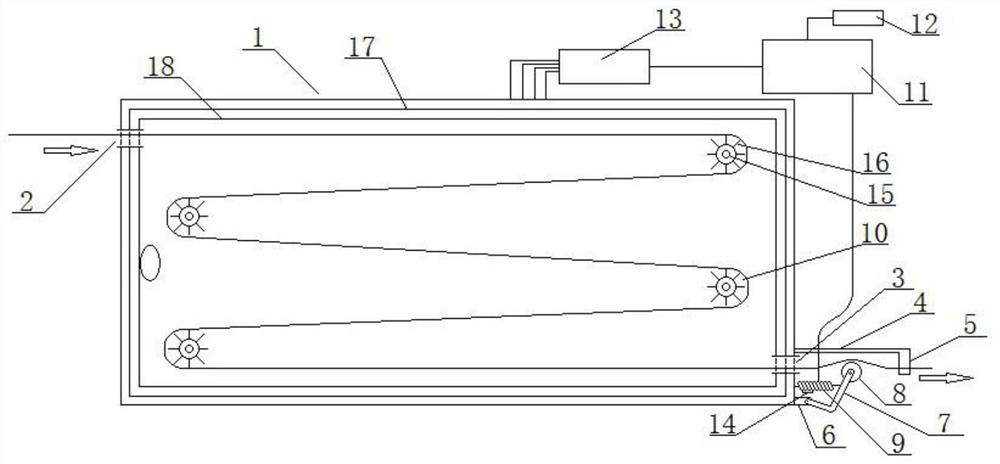

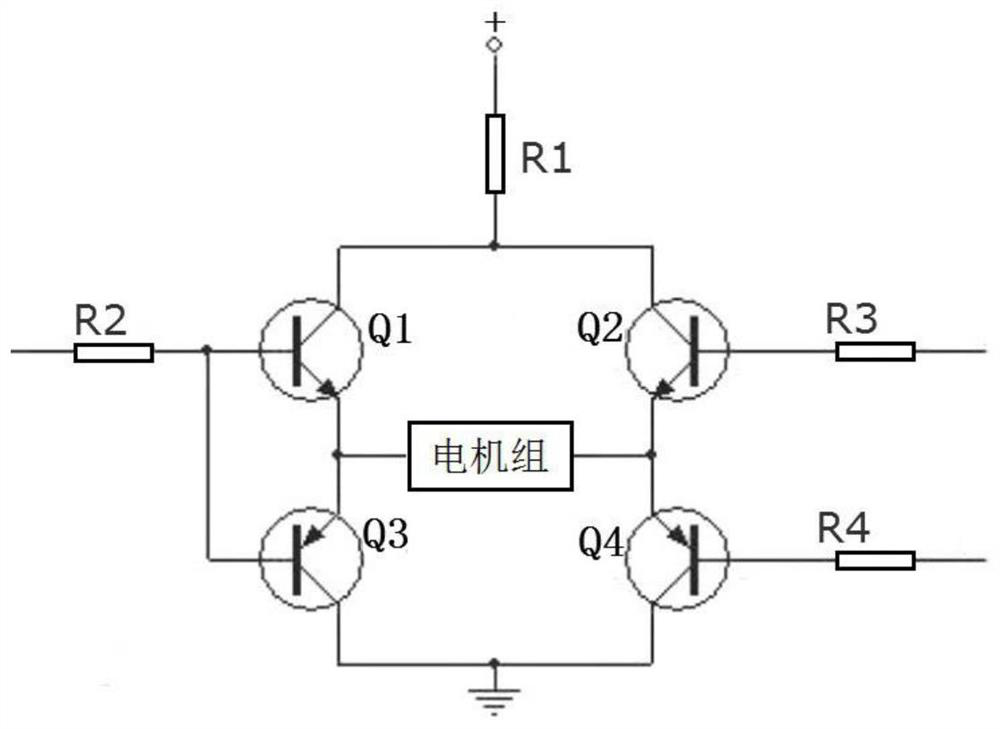

[0021] like figure 1 and figure 2As shown, the present invention designs an assembly line filter cloth oven, which is used to realize the drying operation for the filter cloth soaked in resin, including the oven body 1, the heating body device arranged on the inner wall of the oven body 1, and the oven body The filter cloth inlet 2 and the filter cloth outlet 3 are respectively arranged on the two opposite ends of the 1, the filter cloth inlet 2 and the filter cloth outlet 3 are both arranged horizontally, and the width of the filter cloth inlet 2 and the width of the filter cloth outlet 3 are both the same as the width of the filter cloth Adapt to the width of the cloth, the filter cloth enters the inside of the oven body 1 from the filter cloth inlet 2, and outputs the oven body 1 from the filter cloth outlet 3; it a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com