Liquid seal device of tower tray of bubble-cap tower

A technology for a liquid sealing device and a tower tower is applied in the field of liquid sealing devices of a bubble cap tower tray, which can solve the problems of cracking of welds, reducing the contact between liquid and gas, and large working temperature difference, so as to facilitate installation and disassembly, reduce Weld cracks and the effect of improving work effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

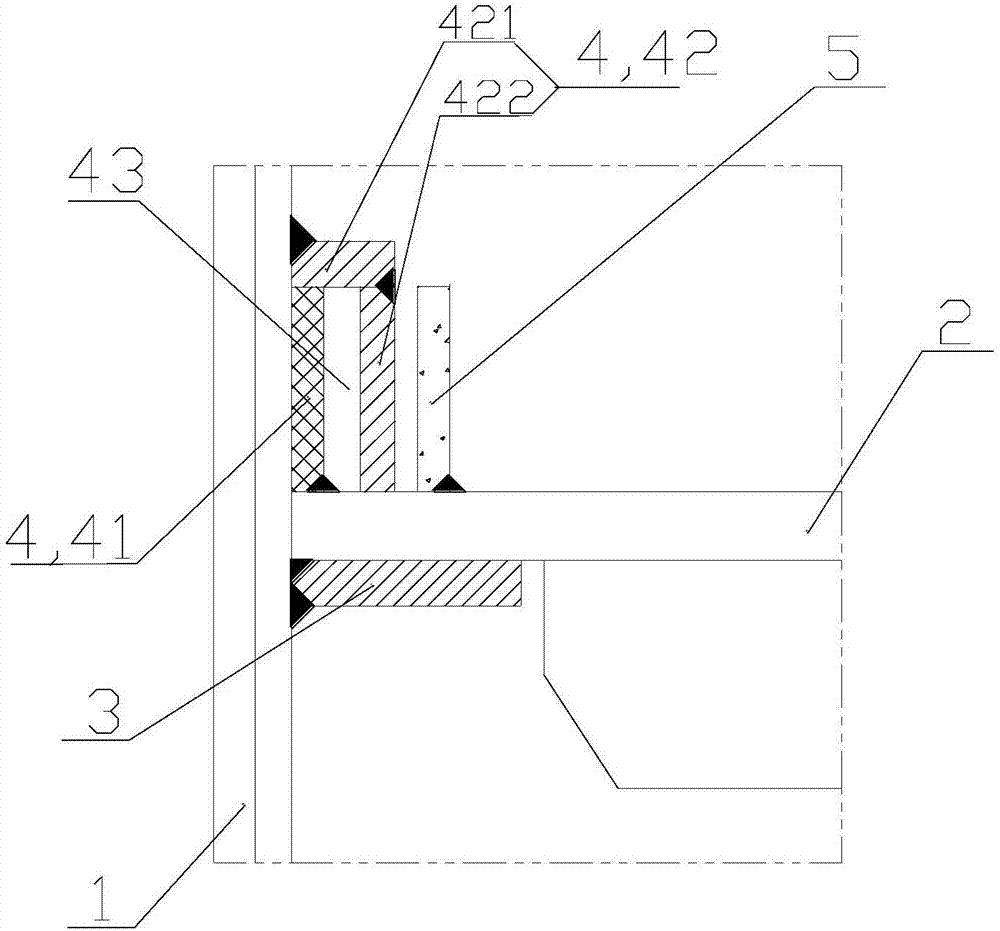

[0033] Such as figure 1 As shown, the present embodiment provides a liquid seal device for the bubble column tray 2, the tray 2 and the liquid seal device are arranged in the tower body 1 of the bubble column, and the liquid seal device includes a support structure 3 and a liquid seal structure 4 . The supporting structure 3 is a supporting ring plate, which is arranged horizontally, and the outer circumference of the supporting ring plate is seamlessly fixedly connected with the inner wall of the tower body 1, preferably by welding. The tray 2 is placed on the supporting ring plate and is not welded with the tower body 1 .

[0034] The liquid seal structure 4 includes a first liquid seal plate 41 and a second liquid seal plate 42 coaxial with the tray 2 and arranged along the circumference of the tray 2, and the second liquid seal plate 42 is arranged on the first Inside the liquid seal plate 41, the upper end of the second liquid seal plate 42 is seamlessly fixedly connect...

Embodiment 2

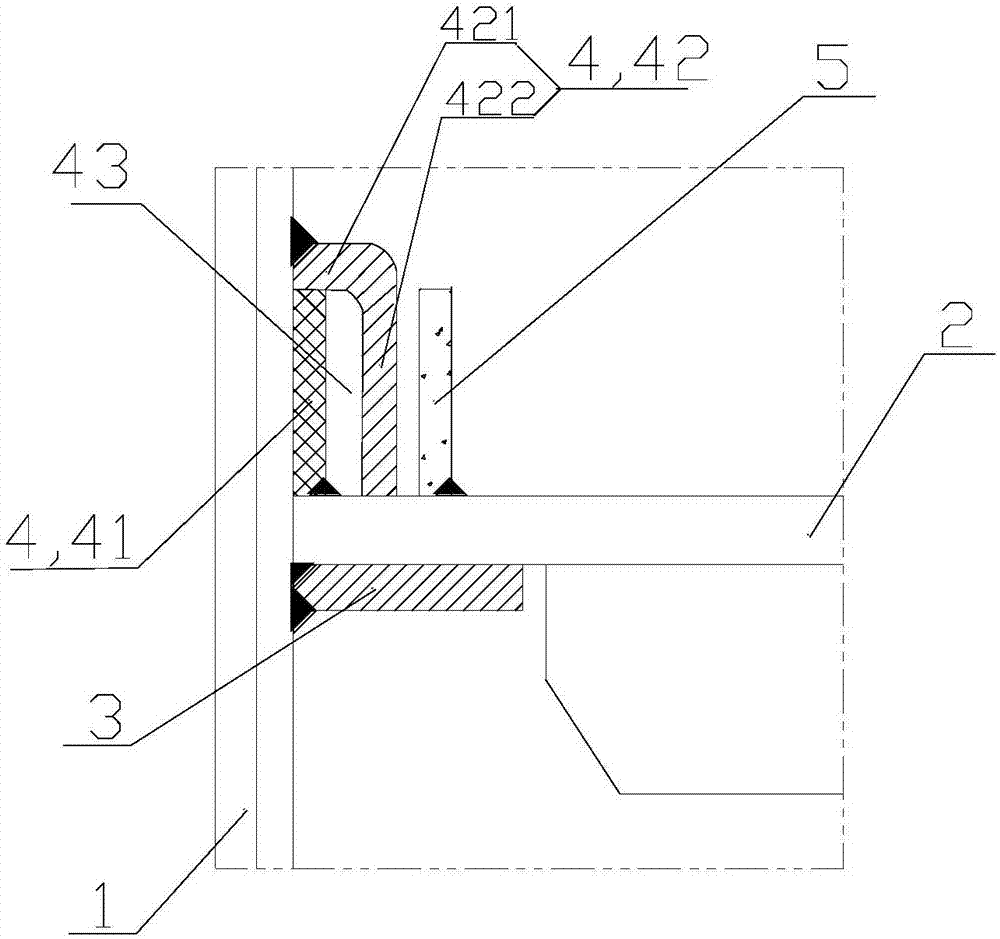

[0046] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that, in the liquid sealing device of the bubble column tray 2 of this embodiment, the horizontal annular baffle 421 and the vertical annular baffle 422 of the second liquid sealing plate 42 are integrated Formed, the vertical annular baffle 422 is located on the inner peripheral edge of the horizontal annular baffle 421 , and the horizontal annular baffle 421 and the vertical annular baffle 422 smoothly transition to form an arc-shaped second liquid seal plate 42 .

[0047] The second liquid seal plate 42 of this embodiment is integrally formed, has good stability and is easy to install, and forms an arc from top to bottom, and the side of the second liquid seal plate 42 in contact with the liquid has less blocking effect on the flow of liquid , and it is not easy to accumulate residues.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that, in the liquid seal device of the bubble column tray 2 of this embodiment, the second liquid seal plate 42 is an annular baffle plate arranged obliquely, and faces the tray from top to bottom. The direction of the central axis of 2 gradually shrinks, and the section of the formed liquid seal chamber 43 is approximately triangular. The upper end of the second liquid seal plate 42 is welded to the tower body 1 at the upper end of the first liquid seal plate 41, and the lower end is horizontal and connected to the tray. 2 touch or stick.

[0050] Further, a reinforcement plate parallel to the first liquid seal plate 41 is provided inside the liquid seal chamber 43 , the upper end of the reinforcement plate is welded to the second liquid seal plate 42 , and the lower end of the reinforcement plate is in contact with or closely attached to the tray 2 . In this way, the strength of the second liquid seal plate 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com