Method for preparing micro-porous carbon-structural electrode material from plant materials and application of micro-porous carbon-structural electrode material

A technology of electrode materials and plant materials, which is applied in the field of electrode materials with microporous carbon structures, can solve the problems of unsatisfactory commercial applications, expensive raw materials, and difficulty in commercial applications, and achieve the benefits of diffusion and electron transmission, The effect of reducing the preparation cost and improving the efficiency of the electrode reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

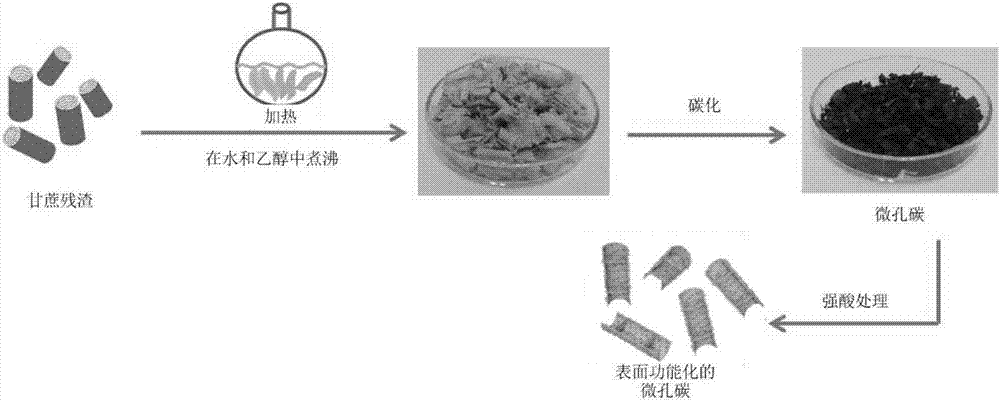

[0036] A green preparation method of a high-performance electrode material with a microporous carbon structure prepared from a plant material such as figure 1 shown, including the following steps:

[0037] Step 1: Removing residual sugar from sugar cane residue

[0038] Squeeze the sugarcane dry and cut into small pieces with a length of 3 cm, boil them in pure deionized water and ethanol for 1.5 hours each, repeat this twice to remove the residual sugar, and then dry them in an oven at 80 degrees for 8 hours Dry it.

[0039] Step 2: Carbonization of Sugarcane Residue

[0040] The dried sugarcane residue obtained in the above step 1 was heated to 900° C. under the atmosphere of protective gas argon, kept for 4 hours, and then naturally cooled to obtain a microporous carbon material.

[0041] Step 3: Surface functionalization of microporous carbon materials

[0042] Soak the microporous carbon material prepared in step 2 in a solution prepared by 3:1 volume ratio of 98% con...

Embodiment 2

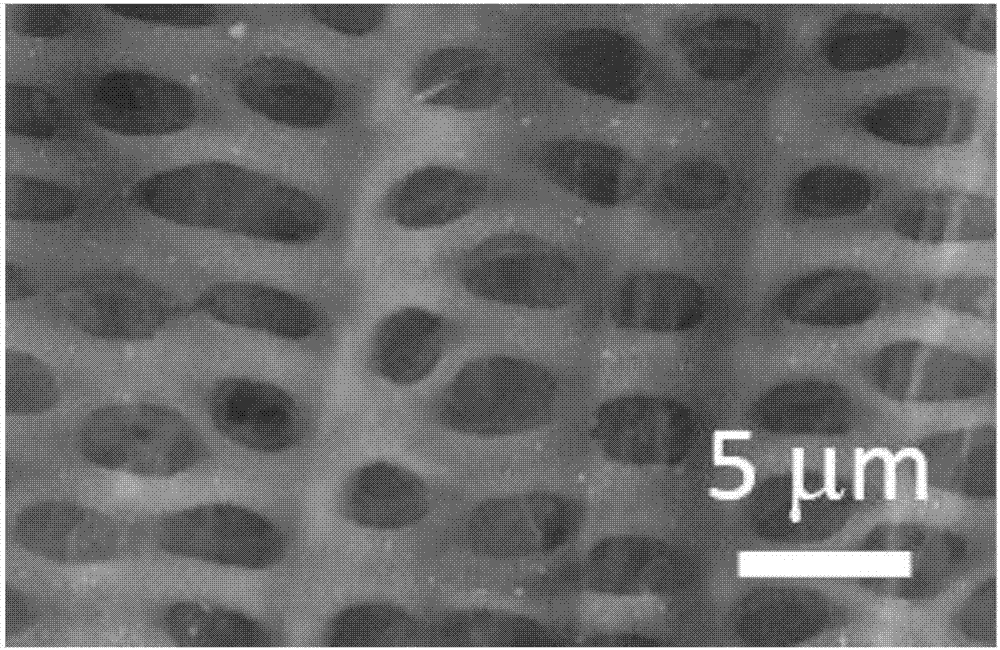

[0044] A high-performance electrode material with a plant material microporous carbon structure of the present invention, the microporous carbon structure is loose and porous, the pore size is 3.5 microns, and the surface is rich in hydroxyl, carboxyl and carbonyl and other nutrient-containing functional groups. These oxygen-containing functional groups will be on the carbon surface These surface defects provide more reaction sites for lithium ion storage, and the adsorption of lithium ions on oxygen-containing functional groups also provides additional lithium ion storage capacity.

[0045] The green preparation method of the high-performance electrode material of the plant material microporous carbon structure comprises the following steps:

[0046] Step 1: Removing residual sugar from corn stalk residue

[0047] Squeeze the corn stalks dry and cut them into small pieces with a length of 4 cm, boil them in pure deionized water and ethanol for 1 hour each, and repeat this thr...

Embodiment 3

[0054] A green preparation method of a high-performance electrode material with a microporous carbon structure prepared from a plant material comprises the following steps:

[0055] Step 1: Removing residual sugar from sorghum residue

[0056] Squeeze the sorghum dry and cut it into small pieces with a length of 5 cm, boil it in pure deionized water and ethanol for 2 hours each, repeat this twice to remove the residual sugar, and then dry it in an oven at 100 degrees for 10 hours Dry it.

[0057] Step 2: Carbonization of Sugarcane Residue

[0058] The dried sugarcane residue obtained in the above step 1 is heated to 1100° C. under the atmosphere of protective gas argon, kept for 5 hours, and then naturally cooled to obtain a microporous carbon material.

[0059] Step 3: Surface functionalization of microporous carbon materials

[0060] Soak the microporous carbon material prepared in step 2 in a solution prepared by 3:1 volume ratio of 98% concentrated sulfuric acid and 70%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com