A method for preparing graphene/sodium manganate flexible film and a method for preparing aqueous sodium-zinc composite battery using it

A flexible thin film, composite battery technology, applied in graphene, battery electrodes, secondary batteries and other directions, can solve the problems of low conductivity, unstable electrochemical performance, cumbersome preparation process, etc., to improve the conductivity and improve the electrochemical performance. Performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

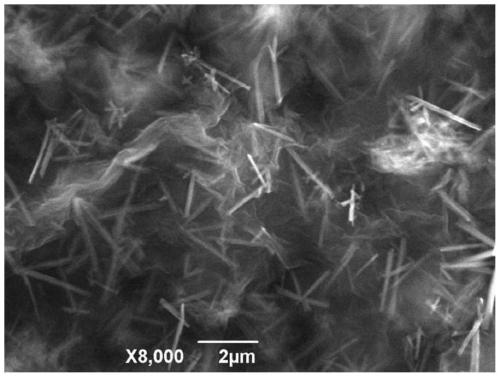

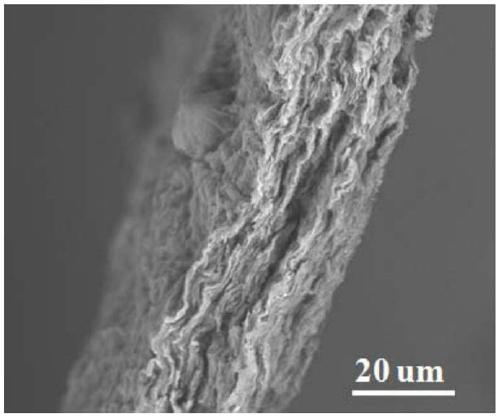

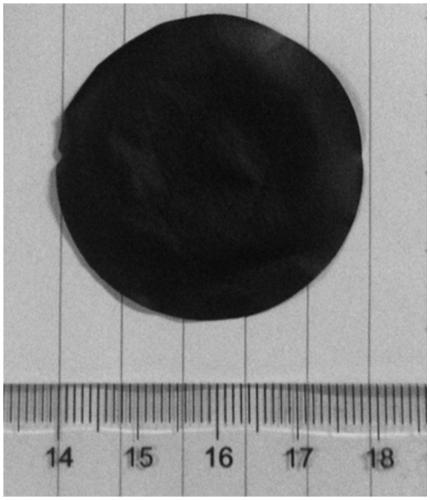

[0030] Specific embodiment one: present embodiment is a kind of method for preparing graphene / sodium manganate flexible film, specifically completes according to the following steps:

[0031] 1. Mn 2 o 3 Add it into the NaOH solution with a concentration of 5mol / L, and then stir and react for 30min to 150min at a stirring speed of 300r / min to 1200r / min to obtain Mn 2 o 3 solution; the Mn 2 o 3 Transfer the solution to a hydrothermal reaction kettle, and then keep the temperature at 120°C to 250°C for 10h to 60h to obtain the reaction product; use distilled water to wash the reaction product for 3 to 5 times, and then heat it at a temperature of 50°C to 100°C Dry for 5h-12h to get Na 4 mn 9 o 18 powder;

[0032] Mn described in step 1 2 o 3 The volume ratio of the amount of the substance and the NaOH solution whose concentration is 5mol / L is (1mmol~2mmol): 30mL;

[0033] 2. Add graphene oxide into deionized water, and then ultrasonically disperse at room temperature ...

specific Embodiment approach 2

[0046] Specific embodiment 2: the difference between this embodiment and specific embodiment 1 is: Mn described in step 1 2 o 3 The volume ratio of the amount of the substance to the NaOH solution whose concentration is 5mol / L is (1.5mmol~2mmol):30mL. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the mass of graphene oxide described in step 2 to deionized water is (30mg-40mg): 10mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com