High-throughput preparation method and applications of material, and apparatus for high-throughput preparation of material

A high-throughput, conveying device technology, applied in the field of materials, can solve the problems of difficulty in control, cannot guarantee only a single variable of cooling rate, a single cooling rate, etc., to achieve the effect of fast cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention discloses a high-throughput preparation method of materials, including:

[0039] The material sample is heated and held, and then the held material sample is held in place and cooled from one end of the held material sample.

[0040] This application provides a high-throughput preparation method for materials, which is to heat the material sample and then keep it warm, then keep the material sample in place and cool it from one end, so as to efficiently obtain materials with different microstructures at one time. A collection of materials with high performance and performance is a high-throughput material preparation method.

[0041] In the high-throughput preparation process of materials, the materials are solid state materials in the general sense of the art, including metal materials, ceramic materials and composite materials, and the metal materials are metal materials well known to those skilled in the art, as Preferably, th...

Embodiment 1

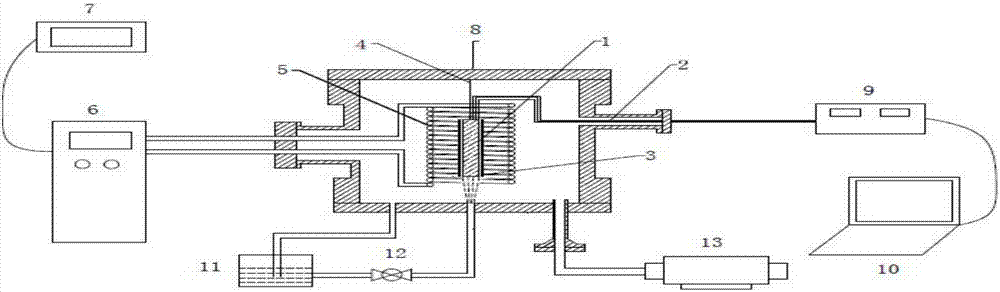

[0069] figure 1It is a schematic diagram of the device of the present invention, the output end of the induction coil power supply is connected with the input end of the induction heating transformer, the output end of the induction heating transformer is connected with the induction heating coil, the coil part of the induction heating coil is arranged inside the furnace body, and the nickel-based superalloy The coil part of the induction heating coil is fixed and hung inside the furnace body by a high-temperature rope. The thermocouple is welded to the end face of the sample that needs to test the temperature. The output end of the thermocouple is set outside the furnace body and is displayed with the thermocouple digital display. The input end of the thermocouple digital display is connected to the input end of the temperature control and recording computer. There is an opening in the furnace body, and a pipe is arranged at the opening. The outlet of the pipe is connected to ...

Embodiment 2

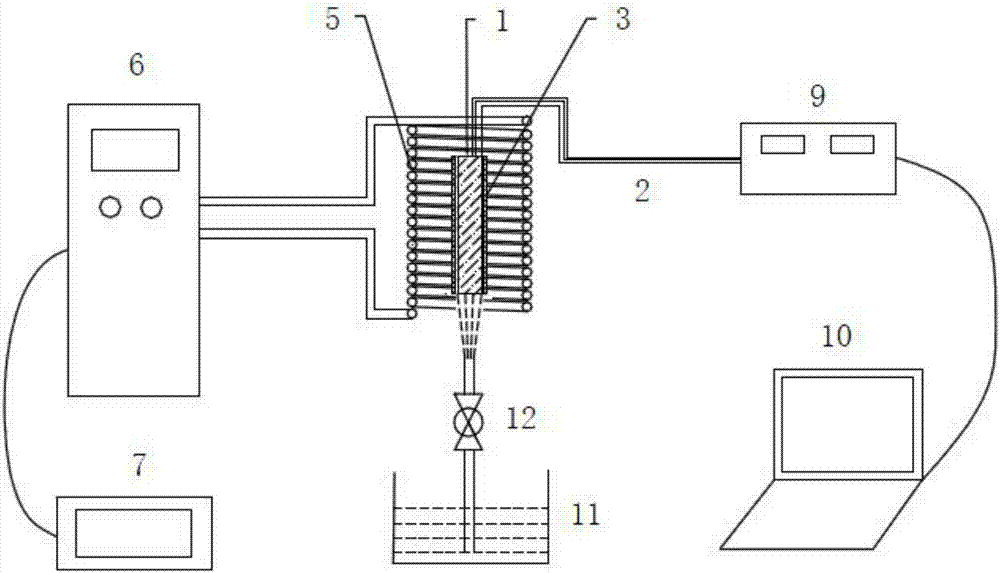

[0071] figure 2 It is a schematic diagram of the device of the present invention, the output end of the induction coil power supply is connected with the input end of the induction heating transformer, the output end of the induction heating transformer is connected with the induction heating coil, the nickel-based superalloy is fixed by the coil part of the induction heating coil, and passed through the high temperature Hanging by rope, the thermocouple is welded to the end surface of the sample that needs to test the temperature, the output end of the thermocouple is connected to the input end of the thermocouple digital display, and the output end of the thermocouple digital display is connected to the input end of the temperature control and recording computer. A circulating water tank is arranged directly below the material sample, the outlet of the circulating water tank is connected to the inlet of the circulating water pump, and the outlet of the circulating water pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com