A liquid film spinning method

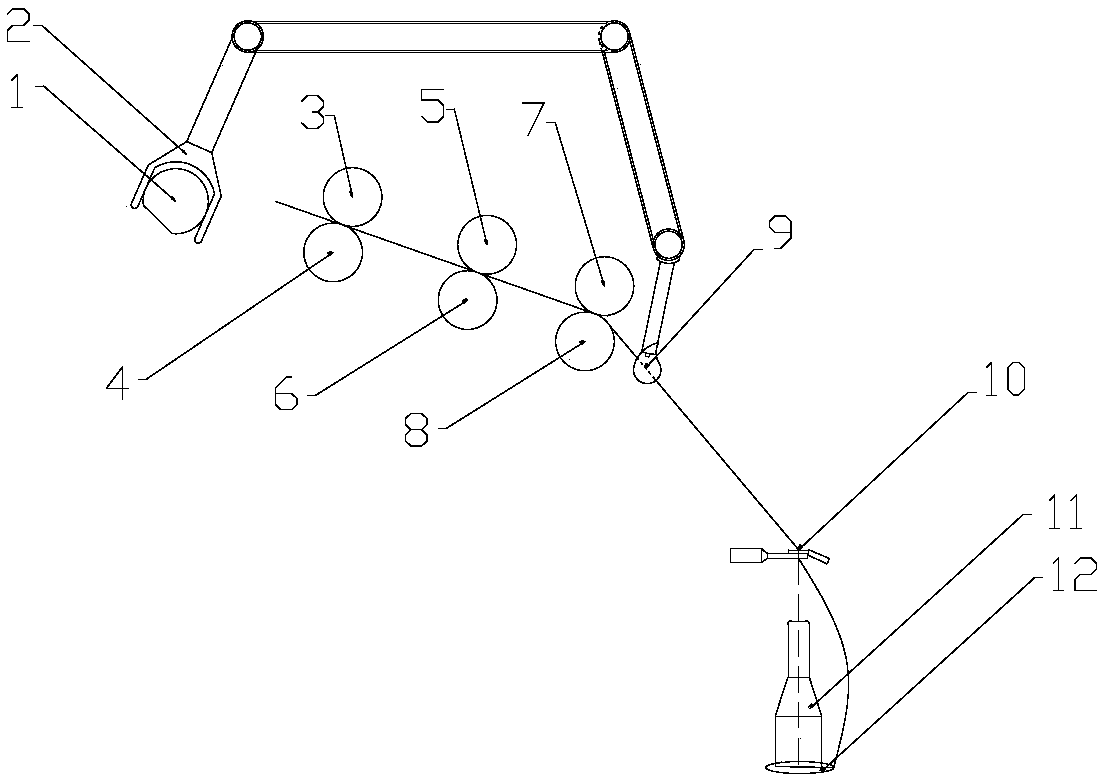

A liquid film and ring spinning technology, which is applied in the spinning field, can solve the problems of high hairiness in spun yarns and high operating costs of machinery and equipment, and achieve the effects of reducing hairiness, moderate softness and hardness, and solving the problem of hard fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the above method, the roving is cotton fiber, the diameter of the water outlet of the dripping device is 4mm, and the distance from the center of the water outlet to the front jaw is 6cm. Yarns with a linear density of 30tex and a twist coefficient of 330 were spun by liquid film spinning, and then the hairiness index was tested with a YG173A hairiness tester. The specific results are shown in Table 1.

Embodiment 2

[0027] According to the above method, the roving is ramie fiber, the diameter of the water outlet of the dripping device is 1 mm, and the distance from the center of the water outlet to the front jaw is 10 cm. A spun yarn with a linear density of 30tex and a twist coefficient of 330 was spun by liquid film spinning, and then the hairiness index was tested with a YG173A hairiness tester. The specific results are shown in Table 1.

Embodiment 3

[0029] According to the above method, the roving is wool fiber, the diameter of the water outlet of the dripping device is 8mm, and the distance from the center of the water outlet to the front jaw is 2cm. Yarns with a linear density of 20tex and a twist coefficient of 315 were spun by liquid film spinning, and then the hairiness index was tested with a YG173A hairiness tester. The specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com