Multi-arm hanging rail type casting cleaning robot

A suspension track and casting cleaning technology, which is applied in the direction of manipulators, program-controlled manipulators, joints, etc., can solve the problem that robots have limited load capacity and cannot meet the needs of heavy weight, large volume and complex heterogeneous castings handling, attitude adjustment and cleaning operations. Bearing castings and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

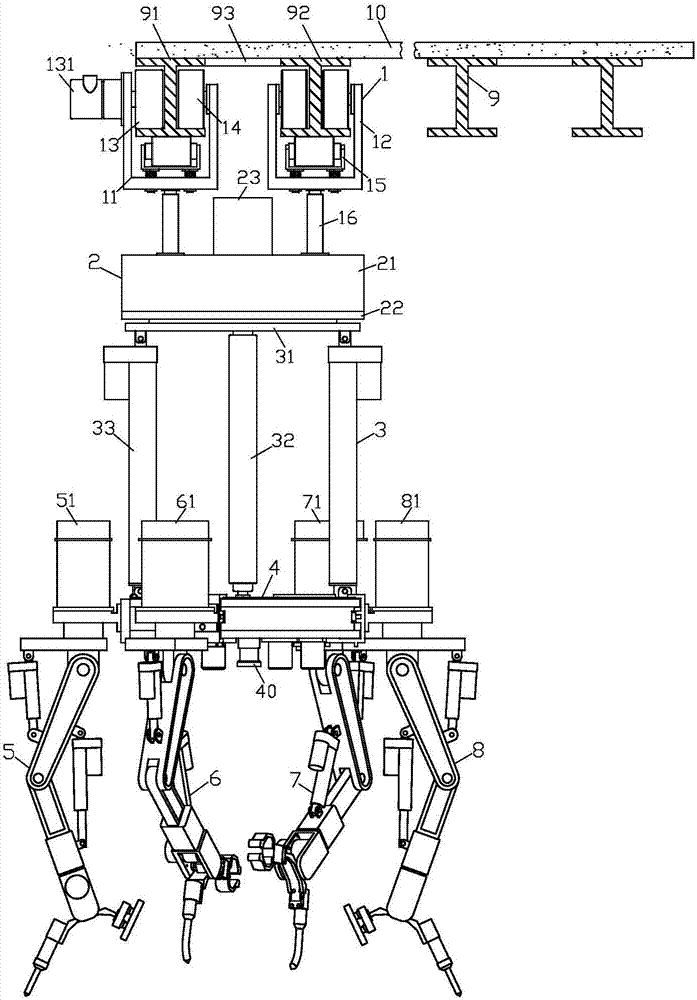

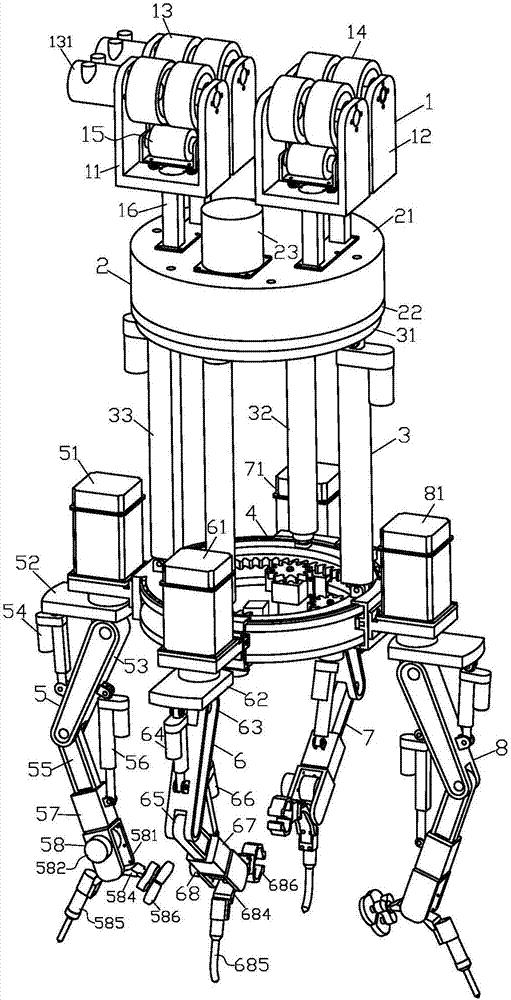

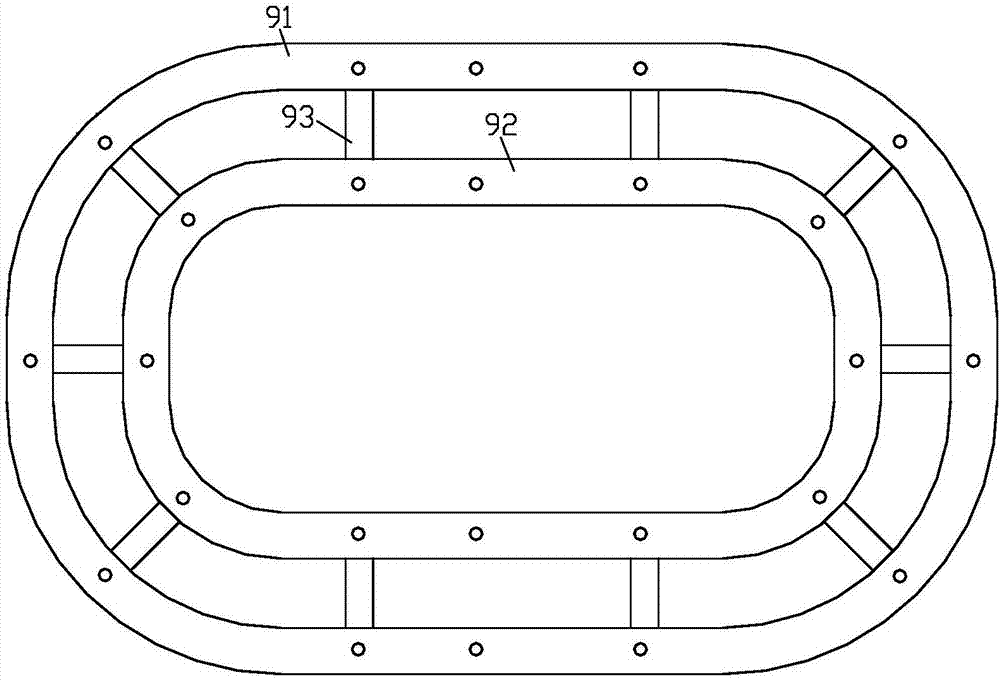

[0029] Such as figure 1 , figure 2 and image 3As shown, a multi-arm suspension track-type casting cleaning robot includes a walking part, an adjustment part and a multi-arm execution part. Wherein, the walking part includes a walking device 1 and a ring track 9, and the ring track 9 includes an outer ring track 91 and an inner ring track 92; the adjustment part includes a turning device 2 and a lifting device 3, and the described The turning device 2 is used to realize the rotation of the lower part of the turning device 2 of the present invention around the axis of the turning device 2, and the lifting device 2 is used to realize the vertical lifting of the present invention. Described walking device 1 is used for driv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com