Guide roll and guide roll assembly fixture

A technology for assembling tooling and guide rollers, applied in guiding/positioning/alignment devices, manufacturing tools, metal processing, etc., can solve problems such as uneven force on guide rollers, first failure of guide rollers, and deformation of oil injection holes, etc., to achieve Reducing processing difficulty, prolonging service life, and adequate lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

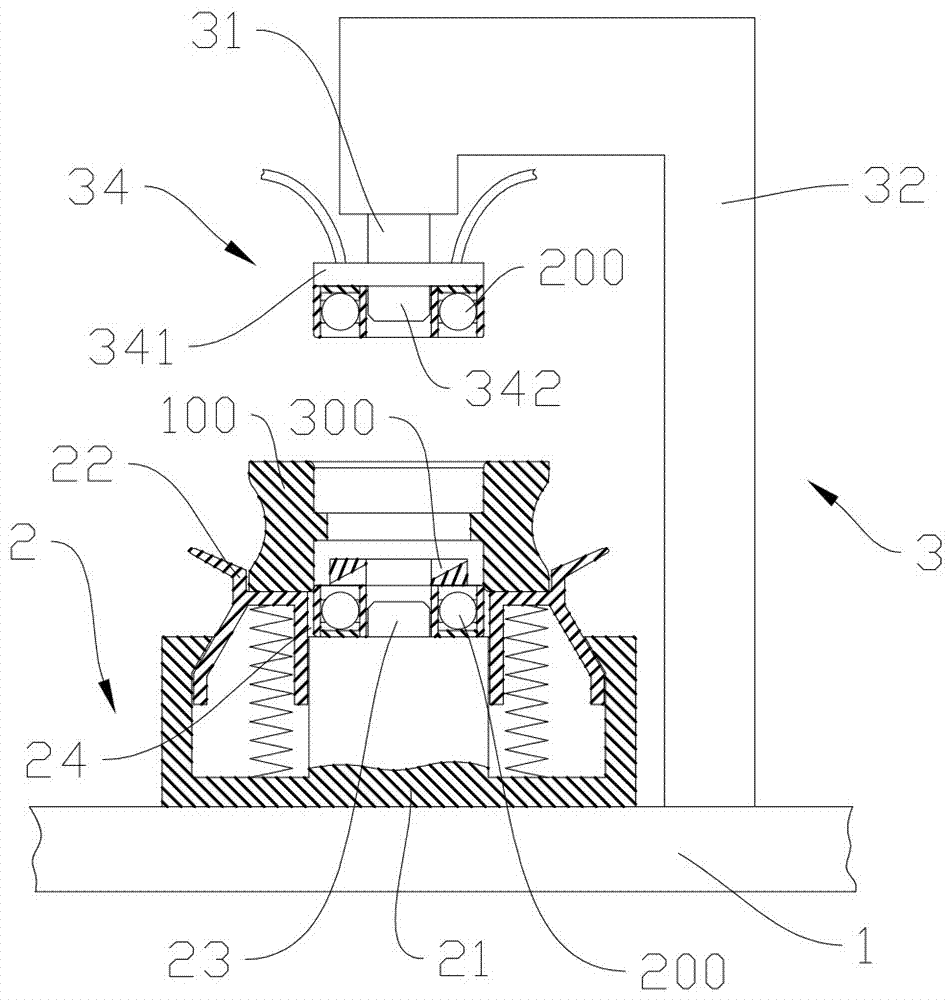

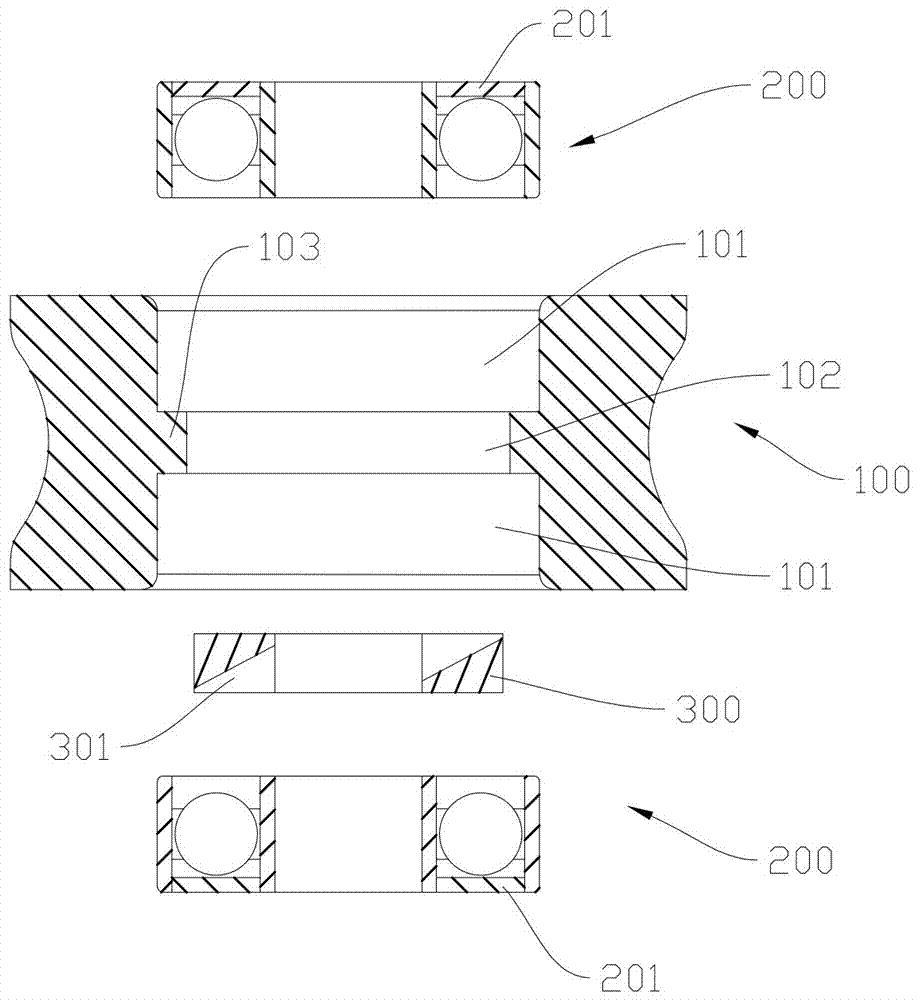

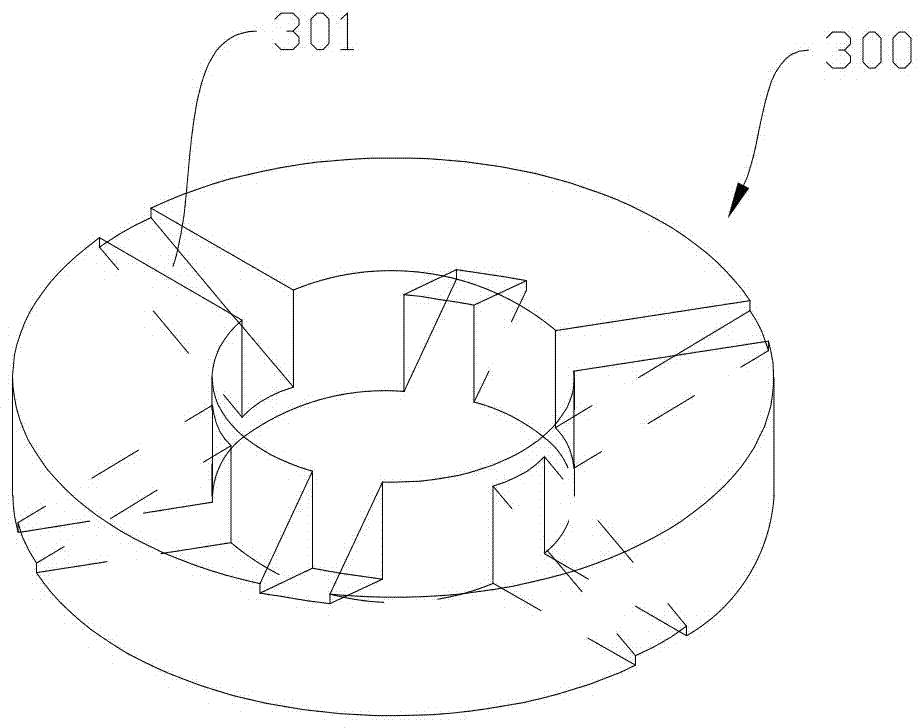

[0031] Embodiment 1: as Figure 1-4 Shown, a kind of guide roller, comprises guide roller body 100, a pair of bearings 200 that set up the upper and lower end faces of guide roller body 100 separately, the oil separator 300 that is installed between bearing 200; The bearing mounting hole 101 of the bearing 200 and the oil separating hole 102 for accommodating the oil separating plate 300 are opened between the bearing mounting hole 101; The end faces covered with the sealing cover are installed facing each other. The outer diameter of the bearing 200 is interference fit with the bearing installation hole 101, and the oil separator 300 is in clearance fit with the oil distribution hole 102. After the guide roller is assembled, the sealing covers 201 on the upper and lower end surfaces of the guide roller body 100 on the two bearings are sealed. It covers the upper and lower end surfaces of the guide roller body 100 to prevent the lubricating grease in the bearing 200 from seep...

Embodiment 2

[0044] Such as Figure 6 As shown, a pair of material platforms can be arranged on the bottom platform, and a pair of pressing heads matching the material platforms can be arranged on the pressing member. In this way, the assembly of two guide rollers is completed at one time, and the two guide rollers are assembled at the same time, and the two guide rollers are used at the same position, which effectively improves the force consistency of the two guide rollers and improves the running stability of the guide rollers, thereby Guarantee and prolong the service life of the guide roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com