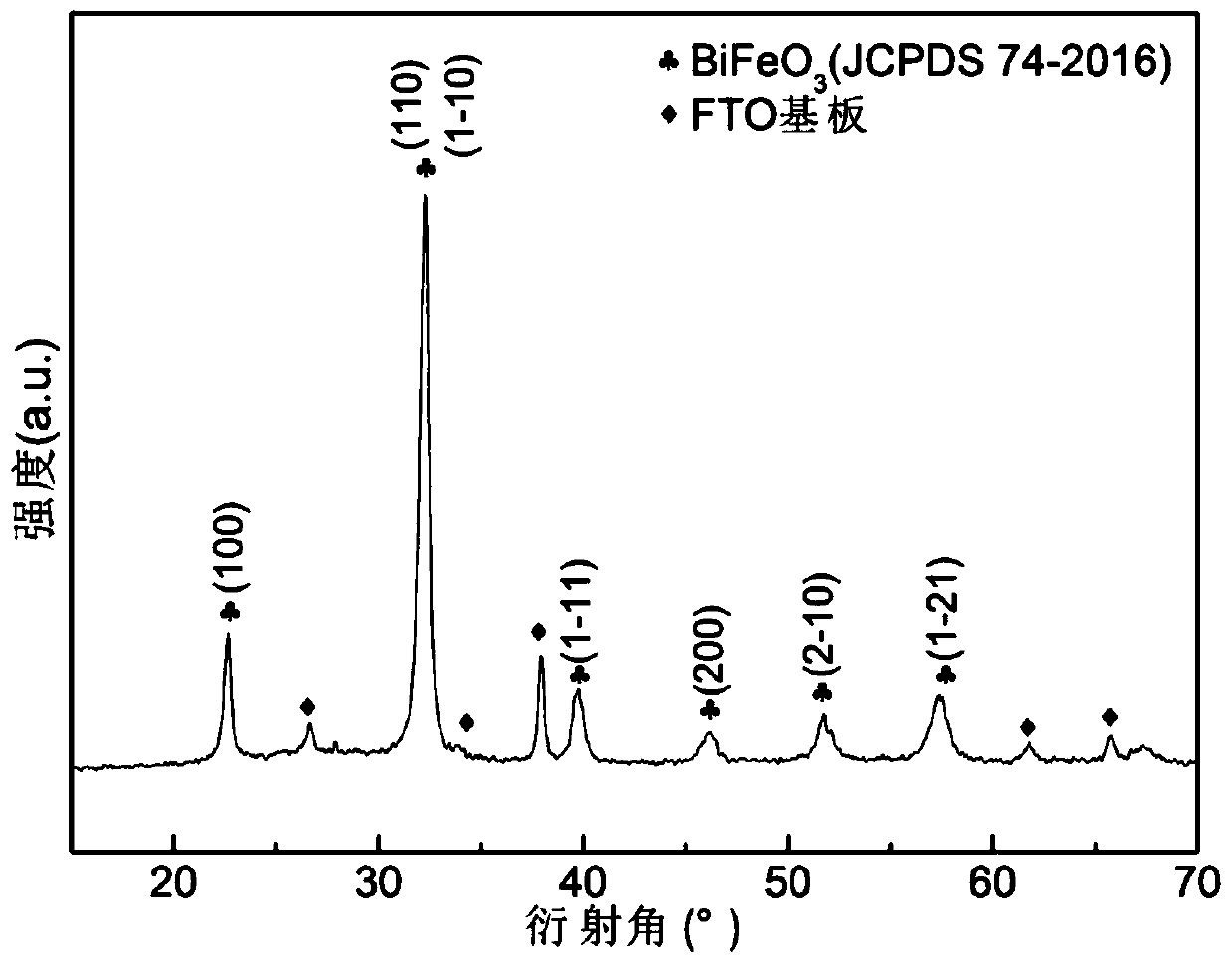

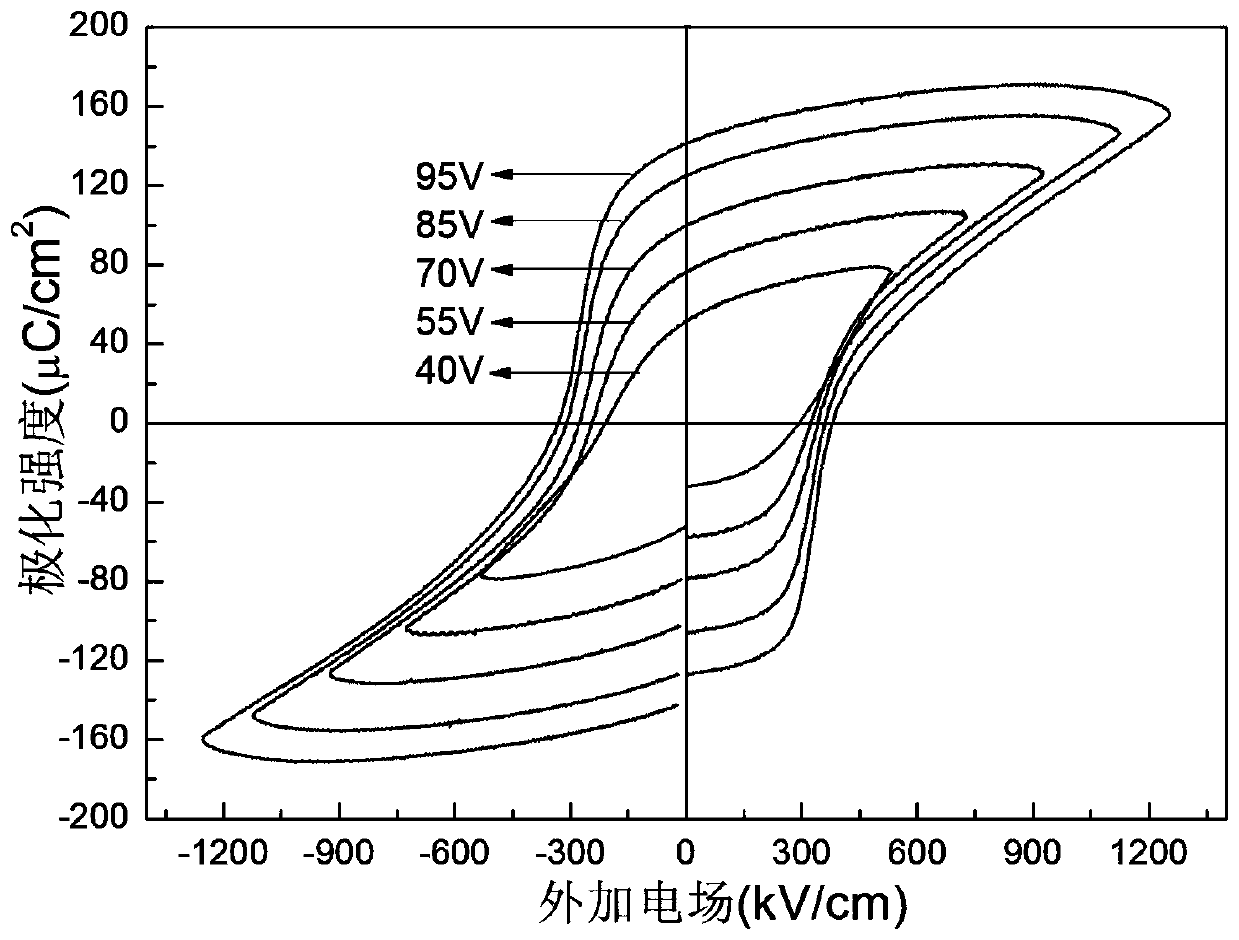

A hosrmnzn co-doped bismuth ferrite ferroelectric thin film with stable ferroelectricity under high electric field and preparation method thereof

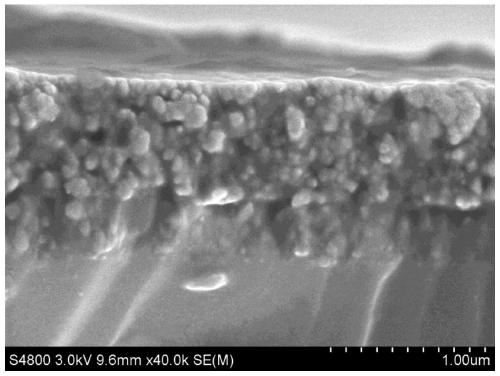

A ferroelectric thin film and ferroelectric technology, applied in the field of HoSrMnZn co-doped bismuth ferrite ferroelectric thin film, to achieve the effect of uniform grain size, stable ferroelectricity and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Using bismuth nitrate, holmium nitrate, strontium nitrate, iron nitrate, manganese acetate and zinc nitrate as raw materials (excess 5% bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.95:0.03:0.02 dissolved in ethylene dichloride In the mixed solution of methyl alcohol ether and acetic anhydride, a stable precursor solution with a total concentration of metal ions of 0.3 mol / L is obtained; wherein the volume ratio of glycol methyl ether and acetic anhydride is 3:1;

[0029] Step 2: Put the FTO / glass substrate in detergent, acetone, and ethanol in order for ultrasonic cleaning. After each ultrasonic cleaning for 10 minutes, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen. Then put the FTO / glass substrate into an oven to bake until dry, take it out and let it stand to room temperature. Then put the clean substrate in an ultraviolet irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanline...

Embodiment 2

[0037] Step 1: Using bismuth nitrate, holmium nitrate, strontium nitrate, iron nitrate, manganese acetate and zinc nitrate as raw materials (excess 5% bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.95:0.03:0.02 dissolved in ethylene dichloride In the mixed solution of methyl alcohol ether and acetic anhydride, a stable precursor solution with a total concentration of metal ions of 0.2mol / L is obtained; wherein the volume ratio of methyl glycol ether and acetic anhydride is 2.5:1;

[0038] Step 2: Put the FTO / glass substrate in detergent, acetone, and ethanol in order for ultrasonic cleaning. After each ultrasonic cleaning for 10 minutes, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen. Then put the FTO / glass substrate into an oven to bake until dry, take it out and let it stand to room temperature. Then put the clean substrate in an ultraviolet irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanlin...

Embodiment 3

[0041] Step 1: Using bismuth nitrate, holmium nitrate, strontium nitrate, iron nitrate, manganese acetate and zinc nitrate as raw materials (excess 5% bismuth nitrate), the molar ratio is 0.94:0.08:0.03:0.95:0.03:0.02 dissolved in ethylene dichloride In the mixed solution of methyl alcohol ether and acetic anhydride, a stable precursor solution with a total concentration of metal ions of 0.4 mol / L is obtained; wherein the volume ratio of glycol methyl ether and acetic anhydride is 3.5:1;

[0042] Step 2: Put the FTO / glass substrate in detergent, acetone, and ethanol in order for ultrasonic cleaning. After each ultrasonic cleaning for 10 minutes, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen. Then put the FTO / glass substrate into an oven to bake until dry, take it out and let it stand to room temperature. Then put the clean substrate in an ultraviolet irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com