A kind of whisker composite high-performance magnesia brick and its manufacturing method

A high-performance, magnesia brick technology, applied in the field of refractory materials, can solve the problems of poor thermal shock stability, large thermal expansion, and environmental hazards of magnesia bricks, and achieve the effects of improving thermal shock stability, high temperature strength, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

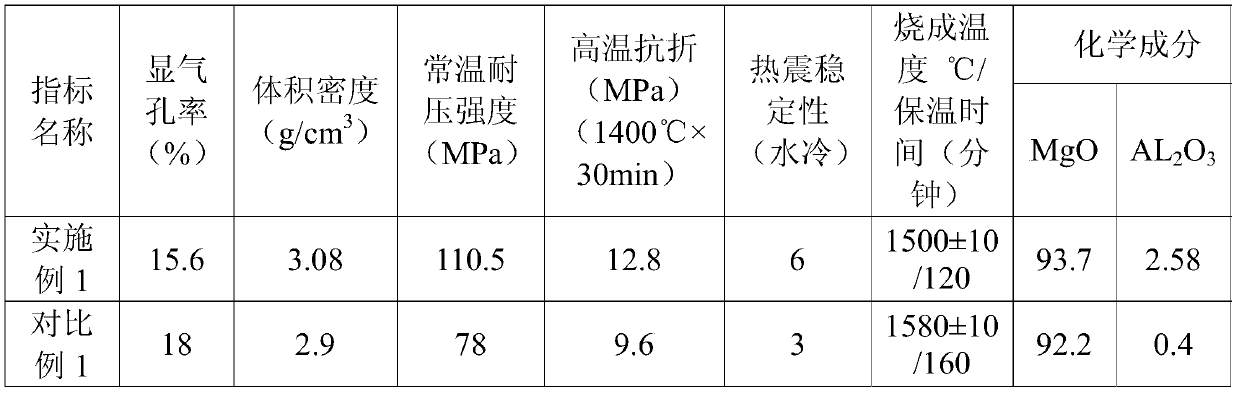

Embodiment 1

[0026] The example of the present invention is used to produce high-performance magnesia bricks for permanent lining of metallurgical furnaces, and its raw materials are proportioned as follows by weight: fused magnesia: 5% for 5-8mm, 10% for 3-5mm, 10% for 3-0.074mm, less than 0.074mm 5%; high-purity magnesia 5-8mm 10%, 3-5mm 5%, less than 0.074mm 5%; recycled waste magnesia brick 3-5mm 15%, 3-0.074mm 12%; magnesia whiskers 10%, magnesium borate Whiskers 8%; binder: nano-scale magnesium aluminate cement dry powder 5%, plus 3.5% pulp.

[0027] The preparation method of the whisker composite high-performance magnesia brick specifically includes the following steps.

[0028] Step (1), preparing aggregates: crushing, sieving and sifting the regenerated waste magnesia bricks, fused magnesia, and high-purity magnesia raw materials through a jaw crusher, a roller crusher, and a Raymond mill, respectively. Grinding, making granular material or fine powder material according to deman...

Embodiment 2

[0041] The formula of the example of the present invention is used to produce the high-performance magnesia brick of the furnace wall of the ferroalloy mining industry, and its raw materials are proportioned as follows by weight fraction: fused magnesia: 5% for 5-8mm, 12% for 3-5mm, 15% for 3-0.074mm, Less than 0.074mm 10%; high-purity magnesia 5-8mm 10%, 3-5mm 6%, 3-0.074mm 5%, less than 0.074mm 5%; recycled waste magnesia brick 3-5mm 5%, 3-0.074mm 10%; oxidation Magnesium whiskers 10%, magnesium borate whiskers 4%; binder: nano-scale magnesium aluminate cement dry powder 3%, plus 3% pulp.

[0042] The preparation method of the whisker composite high-performance magnesia brick specifically includes the following steps.

[0043] Step (1), preparing aggregates: crushing, sieving and sifting the regenerated waste magnesia bricks, fused magnesia, and high-purity magnesia raw materials through a jaw crusher, a roller crusher, and a Raymond mill, respectively. Grinding, making gra...

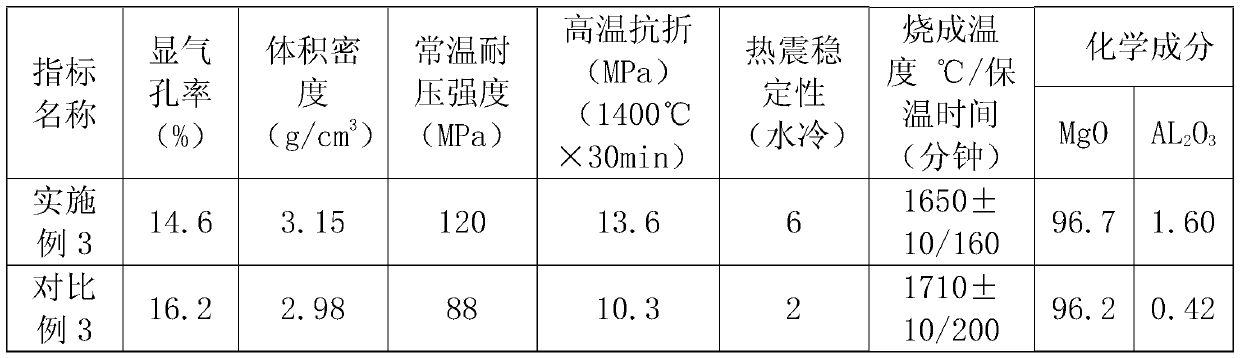

Embodiment 3

[0056] The formula of the example of the present invention is used to produce the high-performance magnesia brick of glass kiln regenerator and cement kiln firing zone, and its raw material proportioning by weight fraction is as follows: fused magnesia: 5-8mm 10%, 3-5mm 15%, 3-0.074mm 17%, less than 0.074mm 10%; high-purity magnesia 5-8mm 5%, 3-5mm 5%, 3-0.074mm 6%; recycled waste magnesia brick 3-5mm 5%, 3-0.074mm 5%; oxidation Magnesium whiskers 15%, magnesium borate whiskers 4%; binder: nano-scale magnesium aluminate cement dry powder 3%, plus 3% pulp.

[0057] The preparation method of the whisker composite high-performance magnesia brick specifically includes the following steps.

[0058] Step (1), preparing aggregates: crushing, sieving and sifting the regenerated waste magnesia bricks, fused magnesia, and high-purity magnesia raw materials through a jaw crusher, a roller crusher, and a Raymond mill, respectively. Grinding, making granular material or fine powder materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com