Preparation technology for magnesium sulfate heptahydrate

A magnesium sulfate heptahydrate, preparation technology, applied in the field of magnesium sulfate preparation, can solve the problems of increased landfill costs, waste of resources, low content, etc., and achieve the effect of reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

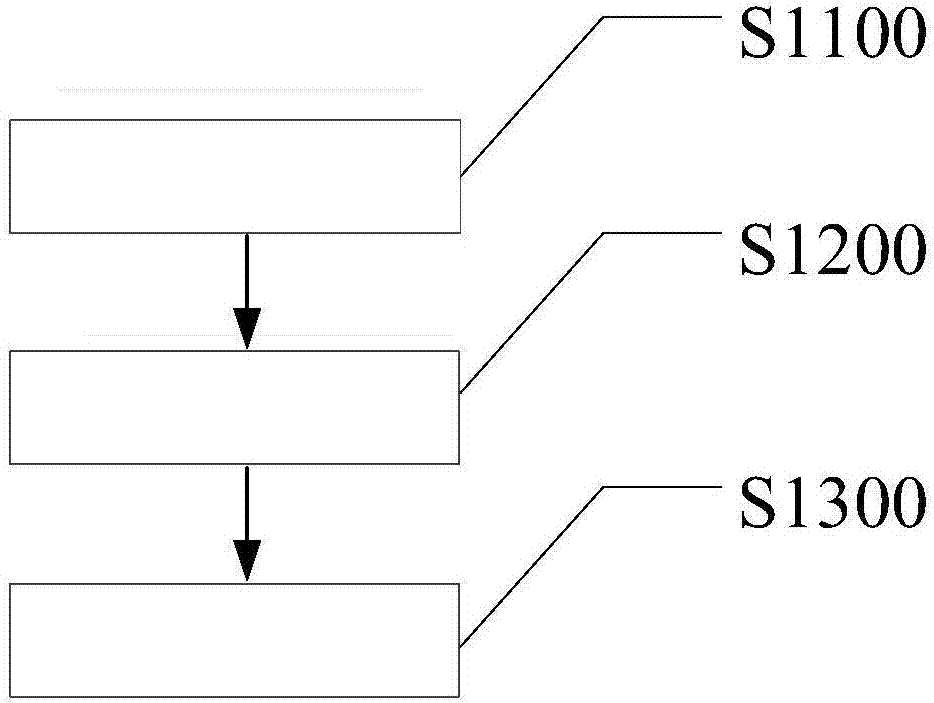

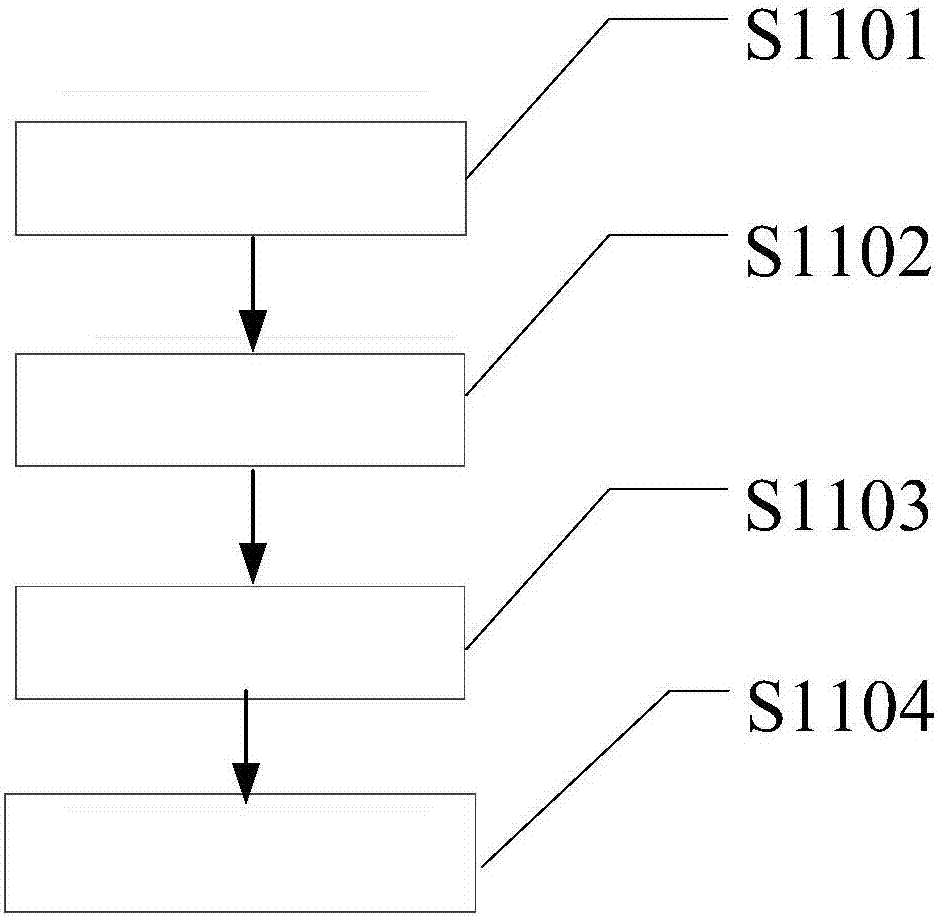

[0061] according to figure 1 As shown, a preparation process of magnesium sulfate heptahydrate first enters the step of S1100 to remove impurities and extract magnesium hydroxide materials: the magnesium hydroxide filter cake formed in the process of extracting lithium from salt lake brine is used as raw material. Wherein in S1100, carrying out impurity removal treatment to the magnesium hydroxide filter cake comprises the following steps: figure 2 As shown, first enter into S1101 to form the first thick matter step: add water to the magnesium hydroxide filter cake, stir and mix to form the first thick matter; S1102 form the second thick matter step: mix the first thick matter Heating the material to 40°C and stirring for 20 minutes to form a second thick material; S1103 Step of forming a second filter cake: the second thick material is passed through a filter press to form a second filter cake; S1104 Step of forming a third filter cake : The second filter cake is washed wit...

Embodiment 2

[0065] according to figure 1 As shown, a preparation process of magnesium sulfate heptahydrate first enters the step of S1100 to remove impurities and extract magnesium hydroxide materials: the magnesium hydroxide filter cake formed in the process of extracting lithium from salt lake brine is used as raw material. Wherein in S1100, carrying out impurity removal treatment to the magnesium hydroxide filter cake comprises the following steps: figure 2 As shown, first enter into S1101 to form the first thick matter step: add water to the magnesium hydroxide filter cake, stir and mix to form the first thick matter; S1102 form the second thick matter step: mix the first thick matter Heating the material to 50°C and stirring for 40 minutes to form a second thick material; S1103 Step of forming a second filter cake: the second thick material is passed through a filter press to form a second filter cake; S1104 Step of forming a third filter cake : The second filter cake is washed wit...

Embodiment 3

[0069] according to figure 1 A preparation process of magnesium sulfate heptahydrate shown, first enters the step of S1100 to remove impurities and extract magnesium hydroxide materials: the magnesium hydroxide filter cake formed in the process of extracting lithium from salt lake brine is used as a raw material. Wherein in S1100, carrying out impurity removal treatment to the magnesium hydroxide filter cake comprises the following steps: figure 2 As shown, first enter into S1101 to form the first thick matter step: add water to the magnesium hydroxide filter cake, stir and mix to form the first thick matter; S1102 form the second thick matter step: mix the first thick matter Heating the material to 45°C and stirring for 25 minutes to form a second thick material; S1103 Step of forming a second filter cake: the second thick material is passed through a filter press to form a second filter cake; S1104 Step of forming a third filter cake : The second filter cake is washed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com