Perforating and rolling method for producing thin-wall seamless steel pipes and special equipment

A seamless steel pipe, thin-walled technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of partial wall and iron ears at the tail of the capillary tube, avoid super-extension phenomenon and reduce heating time. , to avoid the effect of the formation of iron ears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

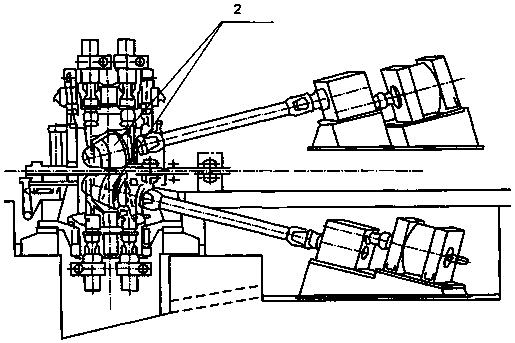

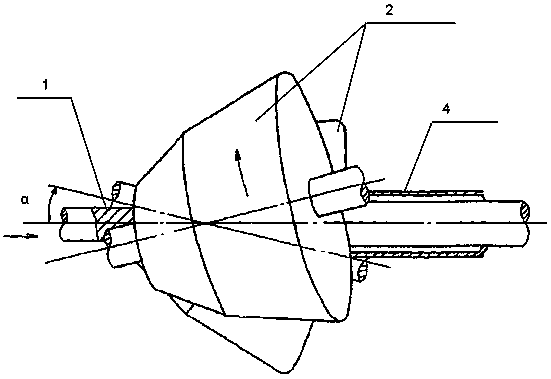

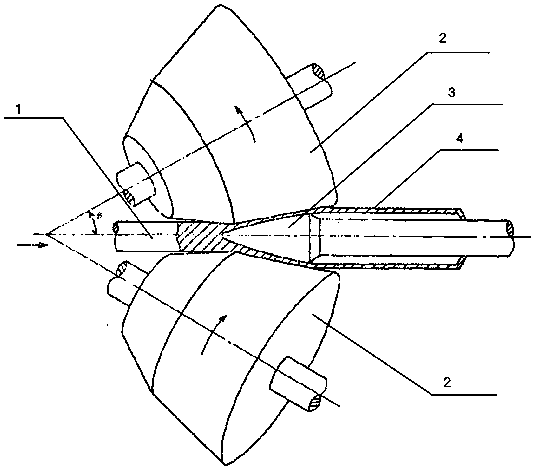

[0035] Example 1, see figure 1 , 2 , 3, 4, 5, a pair of actively rotating tapered rolls 2, a plug 3 and a pair of guide plates 5 are installed as deformation tools for a tapered roll piercer using the existing technology, the tapered rolls 2 are arranged up and down, and the guide plates 5 are arranged around; the tapered roller 2 is used as an external deformation tool, and its function is to rely on friction to drag the tube blank 1 into the pass, driving the tube blank 1 to move forward while rotating, and the plug 3 is used as an internal deformation tool to undertake the perforation of the tube blank 1 Rolling on the inner wall of the capillary 4, the role of the guide plate 5 is to limit the lateral deformation of the capillary 4; the tapered roller 2 is divided into four areas, the perforation preparation area L1, the perforation area L2, the expanding rolling area L3 and the capillary gauge circle area L4 ; In the two areas of the perforation area L2 and the expanding...

Embodiment 2

[0037] Embodiment 2, adopt the equipment of embodiment 1, at the rolling angle α=15 of tapered roll 0 , the bite angle of the tapered roll 9 0 ≤β≤12 0 Under the conditions, take the production capillary diameter Dm=524mm, capillary wall thickness Sm=23mm as an example;

[0038] According to the existing technology, the perforation diameter expansion rate δ is taken in the range of 5-30%, and δ=17.5%; in the prior art, the exit cone angle of the tapered roll λ2=3.9°; γ1 is based on the exit cone angle of the tapered roll λ2 Add a space compensation angle, γ1=λ2+0.6 0 =4.4 0 ;γ2=γ1+(0°—2.5°)=4.4 0 ;γ3=γ2=4.4 0 ;

[0039] According to the technology of the present invention, the perforation diameter expansion rate δ takes a value within the range of 30-45%, and δ=37.5%; the exit cone angle of the tapered roll λ2=6°; γ1 is added according to the exit cone angle λ2 of the tapered roll Compensation angle, γ1=λ2+0.5 0 =6.6 0 ;γ2=γ1+(0°—2.5°)=8.8 0 ;γ3=γ1-(2—2.5°)=6.6 0 -(2...

Embodiment 3

[0045] Embodiment 3, adopt the equipment of embodiment 1, at the rolling angle α=15 of tapered roll 0 , the bite angle of the tapered roll 9 0 ≤β≤12 0 Under the conditions, take the production capillary diameter Dm=430mm, capillary wall thickness Sm=23mm as an example;

[0046] According to the prior art, the perforation diameter expansion rate δ takes a value in the range of 5-30%, and δ=13.1%. In the prior art, the tapered roll exit cone angle λ2=3.9°; γ1 is based on the tapered roll exit cone angle λ2 plus a space compensation angle, γ1=λ2+0.6 0 =4.4 0 ;γ2=γ1+(0°—2.5°)=4.4 0 ;γ3=γ2=4.4 0 ;

[0047] According to the technology of the present invention, the perforation diameter expansion rate δ takes a value in the range of 30-45%, and δ=43.3%; the exit cone angle of the tapered roll λ2=6°; γ1 adds a space according to the exit cone angle λ2 of the tapered roll Compensation angle, γ1=λ2+0.5 0 =6.6 0 ;γ2=γ1+(0°—2.5°)=8.8 0 ;γ3=γ1-(2—2.5°)=6.6 0 -(2—2.5°)=4.5 0 ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com