Ozone catalyst for high-concentration organic nitrogen wastewater treatment

A wastewater treatment and catalyst technology, which is applied in physical/chemical process catalysts, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of low ozone utilization rate, slow hydroxyl radical speed, weak acidity of hydroxyl, etc. Achieve cost reduction, increase utilization rate, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

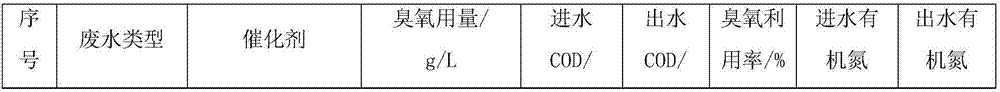

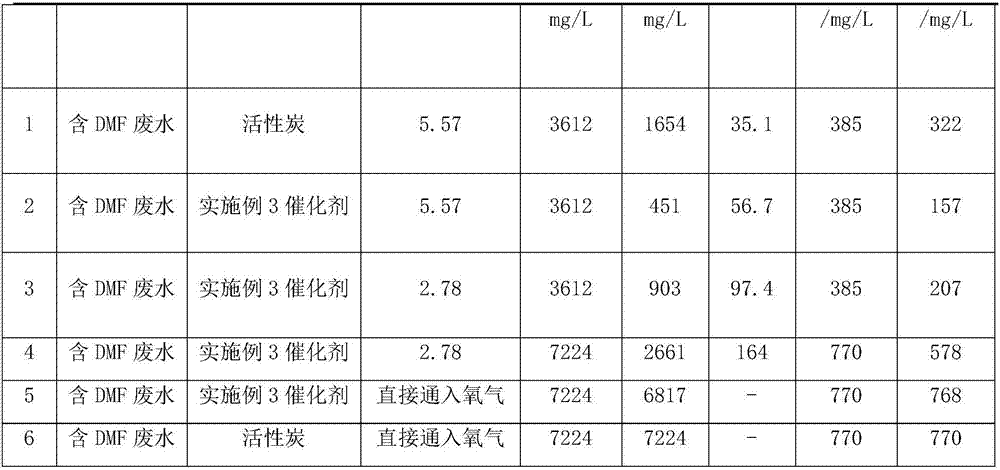

Examples

Embodiment 1

[0025] 1. Roasting: Weigh 100g of activated carbon, place it in a tube furnace, raise the temperature under the protection of nitrogen, and when the temperature reaches 300°C, introduce 7g of sulfur dioxide gas for roasting. After 2 hours of roasting, lower the temperature under the protection of nitrogen, and generate Lots of sulfur oxide groups.

[0026] 2. Impregnation: impregnate the roasted activated carbon in manganese nitrate, bismuth nitrate and lanthanum nitrate aqueous solution, wherein the molar percentage of manganese nitrate, bismuth nitrate and lanthanum nitrate in the impregnating aqueous solution is 8:1:1, take it out after immersion for 12 hours Dry in an oven at 105°C.

[0027] 3. Heat up the impregnated activated carbon under nitrogen protection, and roast at 500°C for 4 hours to obtain an ozone catalyst for high-concentration organic nitrogen wastewater treatment.

Embodiment 2

[0029] 1. Roasting: Weigh 100g of activated carbon, place it in a tube furnace, raise the temperature under the protection of nitrogen, and when the temperature reaches 400°C, feed 2g of sulfur dioxide gas for roasting. After 5 hours of roasting, lower the temperature under the protection of nitrogen, and produce Lots of sulfur oxide groups.

[0030] 2. Impregnation: impregnate the roasted activated carbon in copper nitrate, cobalt nitrate and cerium nitrate aqueous solution, wherein the molar percentage of copper nitrate, cobalt nitrate and cerium nitrate in the impregnating aqueous solution is 8:1:1, take it out after immersion for 24 hours Dry in an oven at 105°C.

[0031] 3. The impregnated activated carbon is heated up under the protection of nitrogen, and roasted at 600°C for 2 hours to obtain an ozone catalyst for the treatment of high-concentration organic nitrogen wastewater.

Embodiment 3

[0033] 1. Roasting: Weigh 100g of activated carbon, place it in a tube furnace, raise the temperature under the protection of nitrogen, and when the temperature reaches 500°C, pass in 2g of sulfur dioxide gas for roasting. After 2 hours of roasting, lower the temperature under the protection of nitrogen, and produce Lots of sulfur oxide groups.

[0034] 2. Impregnation: impregnate the roasted activated carbon in zinc nitrate, molybdenum nitrate and cerium nitrate aqueous solution, wherein the mass percentage of zinc nitrate, molybdenum nitrate and cerium nitrate in the impregnating aqueous solution is 8:1:1, after 36 hours of immersion, take it out in Dry in an oven at 105°C.

[0035] 3. Heat up the impregnated activated carbon under nitrogen protection, and roast at 800°C for 4 hours to obtain an ozone catalyst for high-concentration organic nitrogen wastewater treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com