Duct piece floating resisting structure capable of passing through mine tunnel through shield empty pushing and construction method

A shield segment and construction method technology, applied in tunnels, tunnel linings, mining equipment and other directions, can solve problems such as affecting the construction progress, inconvenient construction, and inability to mass-produce bolts, so as to ensure construction quality, reduce cracking, leakage and other problems. The effect of damage and deformation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

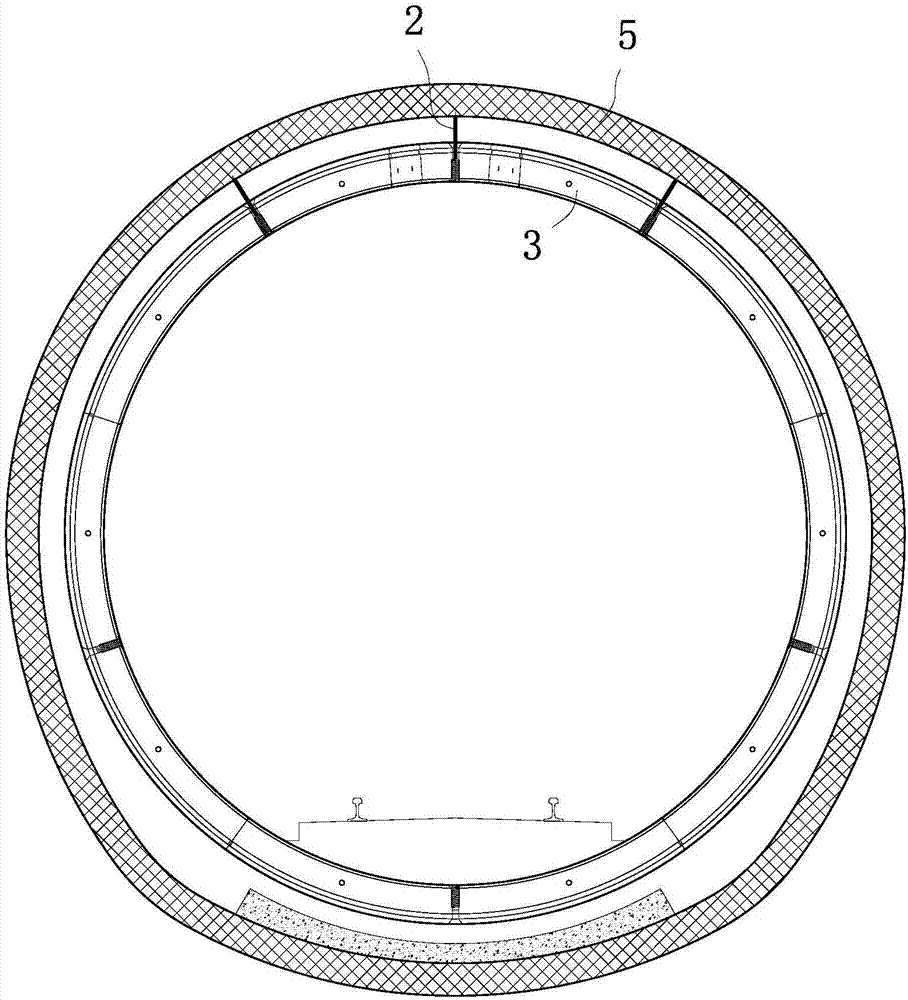

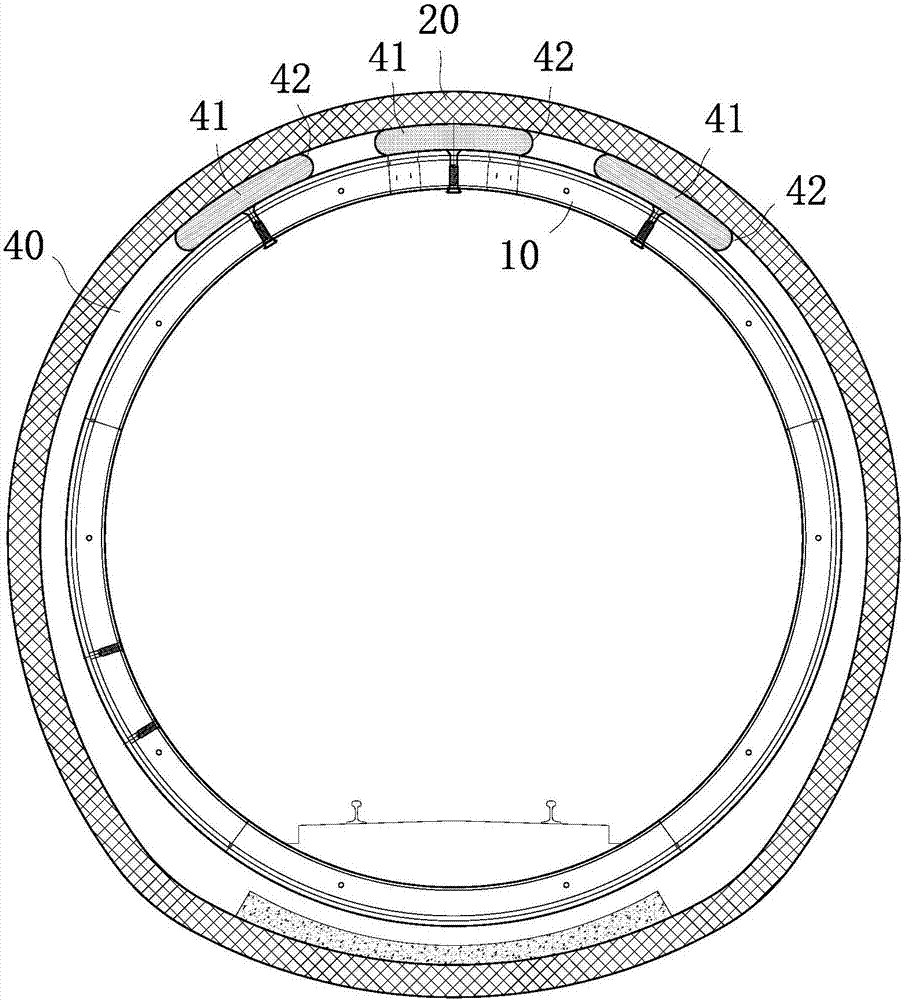

[0027] refer to image 3 and Figure 4 According to the invention, a construction method of a segment anti-floating structure of a shield tunnel pushed through a mine tunnel, comprising the following steps:

[0028] S1: Unscrew the segment screw cap at the grouting hole 11 on the shield segment 10, pass through the grouting hole 11 of the shield segment 10 to the gap 40 between the shield segment 10 and the primary lining 20 of the mining tunnel Insert the grouting bag body 42, and the open end of the grouting bag body 42 stretches out the grouting hole 11 on the shield segment 10;

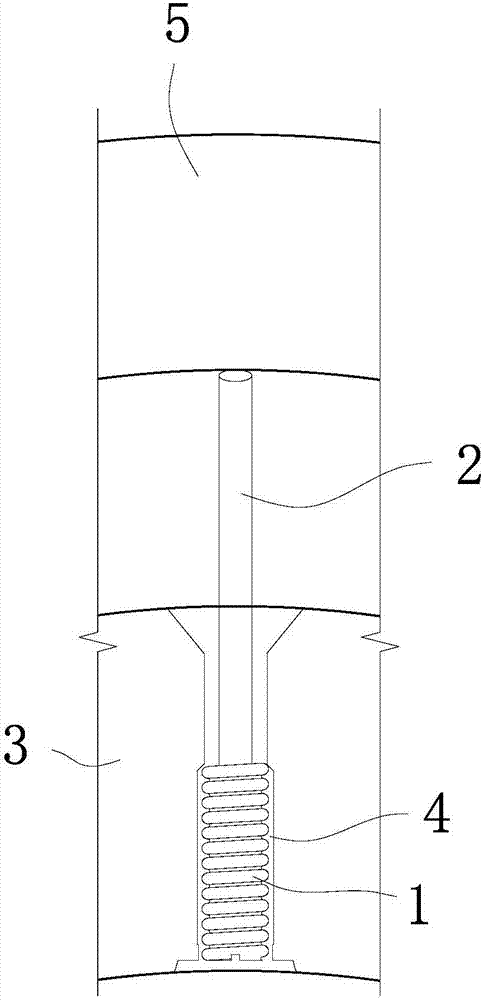

[0029] S2: Screw in the double-fluid grouting pipe component 30 with threads on the outer wall at the grouting hole 11, wherein the double-fluid grouting pipe component 30 has a first grouting pipe 31 and a second grouting pipe extending into the grouting bag and juxtaposed. slurry pipe 32;

[0030] S3: Inject cement slurry and water glass slurry into the grouting bag body 42 through the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com