Coal-pyrolysis-upgrading-based oil product hydrofining system and technique

A technology for hydrorefining and coal pyrolysis, which is applied in the petroleum industry, hydrogen separation, hydrogen sulfide, etc., can solve the problems of difficult hydrogen source, low tar and gas production, and waste oil dumping, etc. The effect of source-to-source puzzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

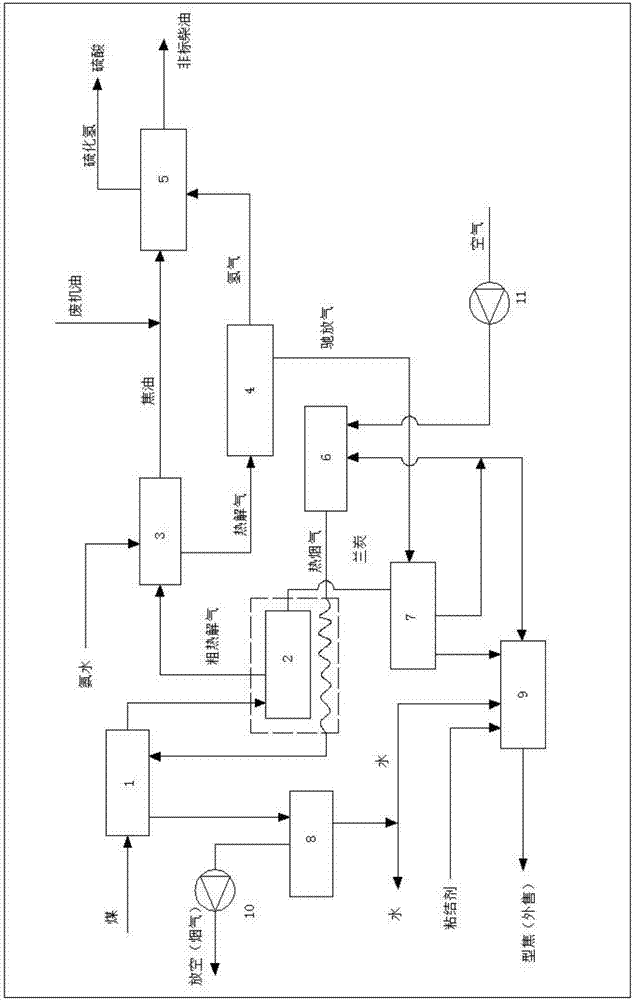

[0015] The system of the present invention includes: coal drying furnace 1, coal pyrolysis upgrading furnace 2, gas combustion chamber 6, water recovery system 8, CDQ chamber 7, cold pressing forming unit 9, gas purification unit 3, pressure swing adsorption hydrogen production Unit 4, oil hydrorefining unit 5, flue gas induced draft fan 10, and air blower 11.

[0016] A system and process for oil hydrofining based on coal pyrolysis and upgrading, the coal outlet of the coal drying furnace 1 is connected to the coal inlet of the coal pyrolysis upgrading furnace 2; the blue coal outlet of the coal pyrolysis upgrading furnace 2 It is connected with the blue carbon inlet of the CDQ chamber 7; the blue carbon outlet of the CDQ chamber 7 is connected with the blue carbon inlet of the cold pressing forming unit 9; the flue gas outlet of the gas combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com