Method for synthesizing totally inorganic CsPbX3 perovskite nano-crystal

A synthesis method and perovskite technology are applied in the field of synthesis of all-inorganic CsPbX3 perovskite nanocrystals, which can solve the problems of poor reproducibility of nanocrystal synthesis, overcome poor reproducibility, have good application prospects, and reduce professional technical requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

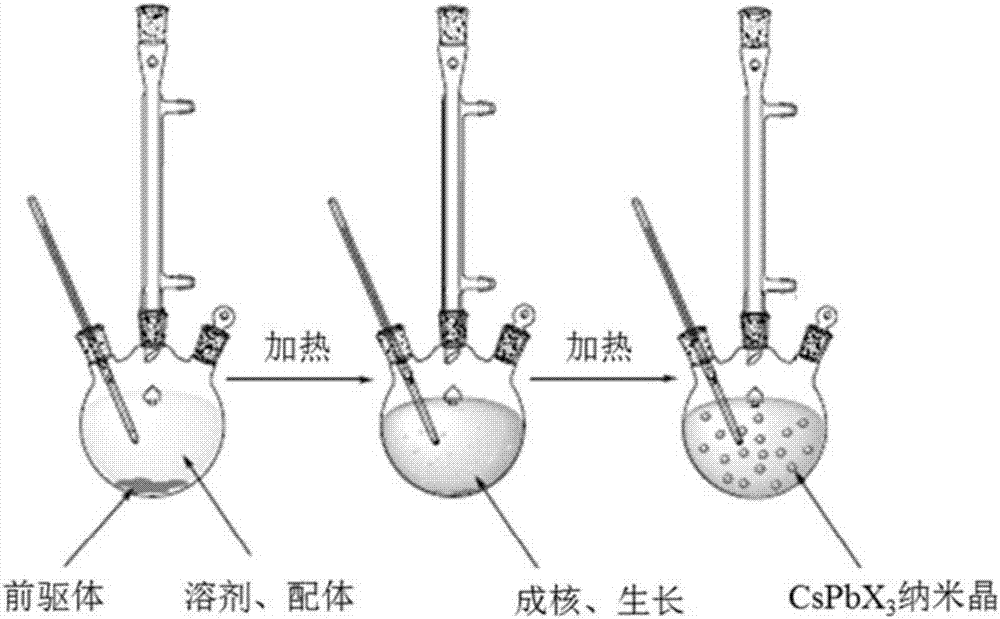

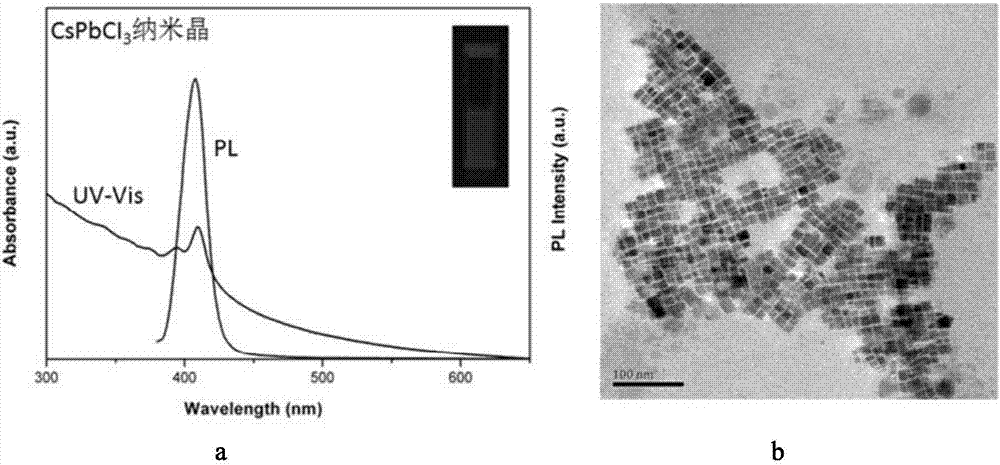

[0022] Such as figure 1 As shown, respectively take 5mL ODE, 0.5mL OA, 0.5mL OAM into a 25mL three-necked flask, and add 16mg Cs at 2500rpm 2 CO 3 , 37mg of lead stearate and 18mg of cyanuric chloride, then directly heated to 140 ° C, and rapidly cooled with ice water, added precipitant ethyl acetate for precipitation, 8000rpm centrifugal washing, discarding the supernatant, obtained as figure 2 CsPbCl shown 3 Nanocrystalline.

Embodiment 2

[0024] Such as figure 1 As shown, respectively take 5mL ODE, 0.5mL OA, 0.5mL OAM into a 25mL three-necked flask, and add 16mg Cs at 2500rpm 2 CO 3 , 37mg lead stearate and 18mg hexachlorocyclotriphosphazene, then directly heated to 120 ° C, and rapidly cooled with ice water, added precipitant ethyl acetate for precipitation, 8000rpm centrifugal washing, discarding the supernatant, obtained as figure 2 CsPbCl shown 3 Nanocrystalline.

Embodiment 3

[0026] Such as figure 1 As shown, respectively take 5mL ODE, 0.5mL OA, 0.5mL OAM into a 25mL three-necked flask, and add 20mg CH at 2500rpm 3 COOCs, 37mg of lead stearate and 18mg of hexachlorocyclotriphosphazene were directly heated to 120°C, cooled rapidly with ice water, added precipitant ethyl acetate for precipitation, centrifuged and washed at 8000rpm, and the supernatant was discarded to obtain Such as figure 2 CsPbCl shown 3 Nanocrystalline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com