A fully automatic stacking equipment suitable for cans of different specifications

A fully automatic, canned technology, applied in the stacking, transportation and packaging of objects, conveyor objects, etc., can solve the problem of not being able to adapt to automatic stacking of cans of various specifications, unable to adapt to stacking of cans of various specifications, and unable to stagger cans Arrangement and other issues, to achieve the effect of high production efficiency, full automation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

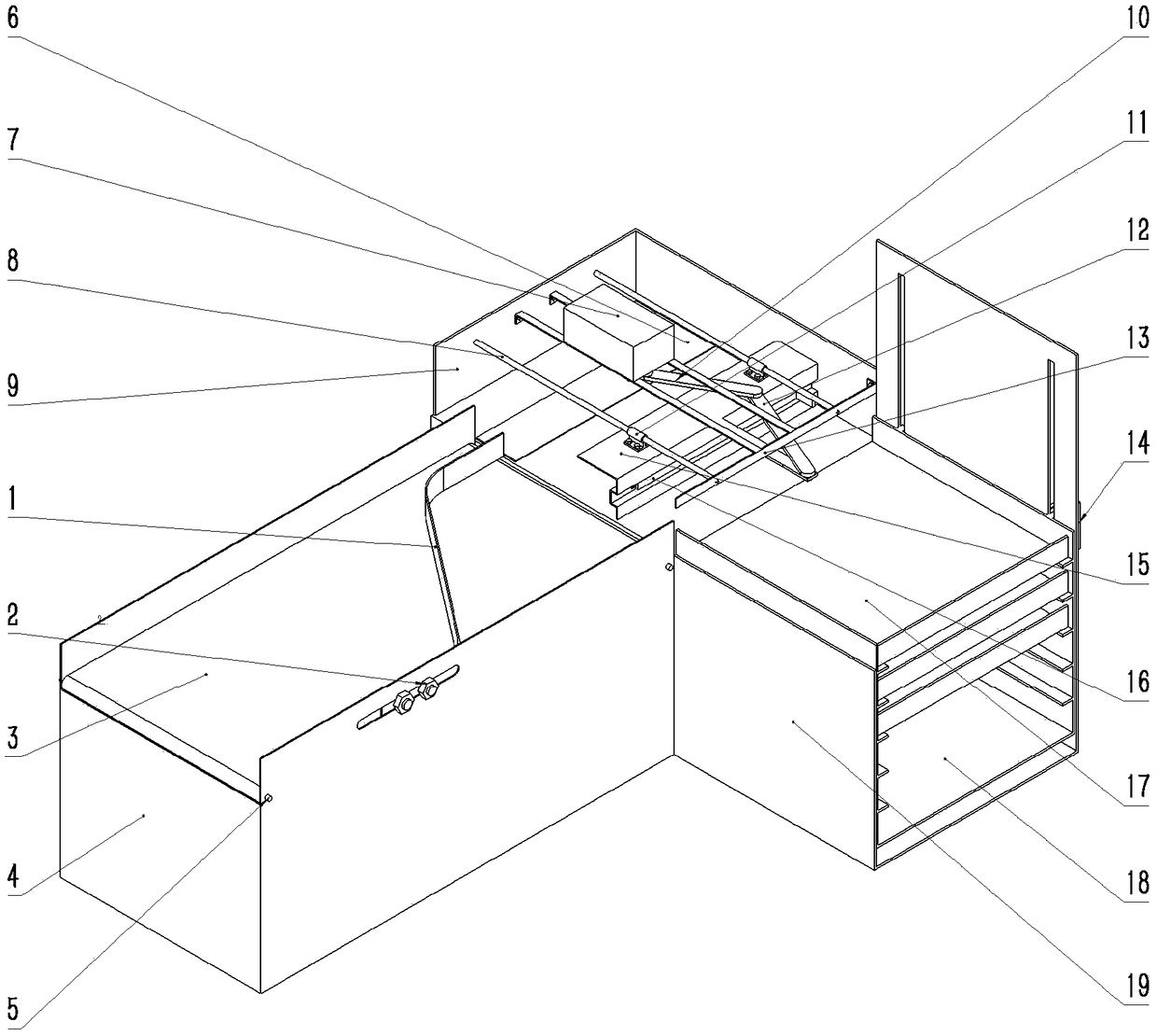

[0020] Such as figure 1 , 2 . As shown in 3, the fully automatic stacking equipment suitable for cans of different specifications is characterized in that it includes: a conveyor, a stacker and a loading platform; the conveyor includes a conveyor box 4, which is installed on the conveyor box Conveyor conveyor belt 3 and adjustable guide plate 1, two conveyor belt pulleys 5 are fixed on the conveyor box 4 one after the other, and the conveyor belt 3 is set on the two conveyor belt pulleys 5, which can be adjusted The guide plate 1 is detachably fixed on the conveyor box, and can be fixed to the long strip-shaped through hole on the side wall of the conveyor box 4 through two guide plate fixing bolts 2;

[0021] Described stacker comprises stacker casing 9, the stacker conveyor belt 6 that is installed on this casing and pushes away mechanism; The movement is guided by the adjustable guide plate 1 and transported to the stacker conveyor belt 6 in sequence;

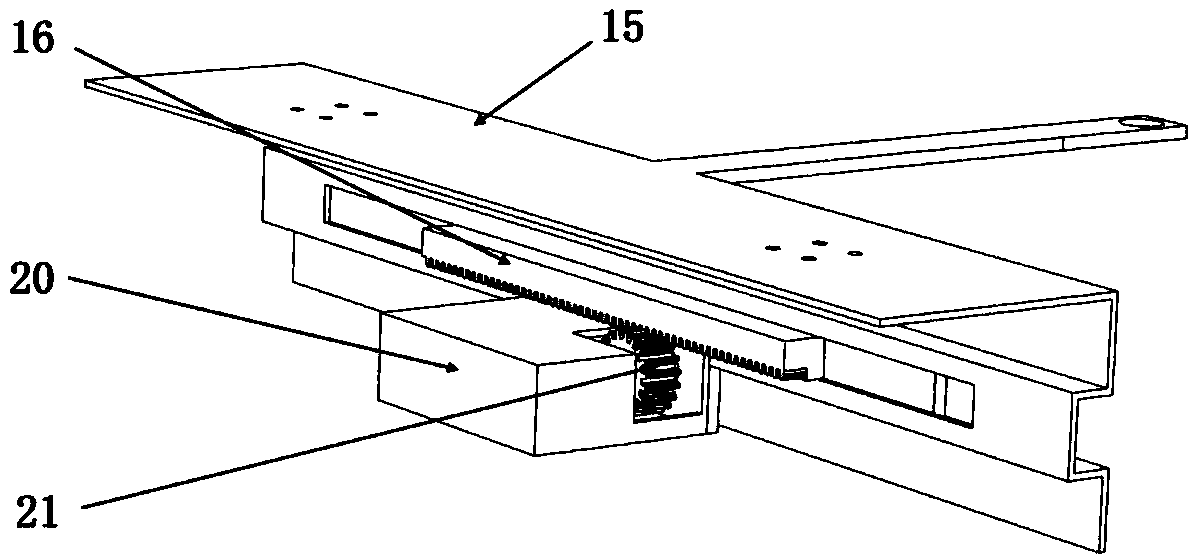

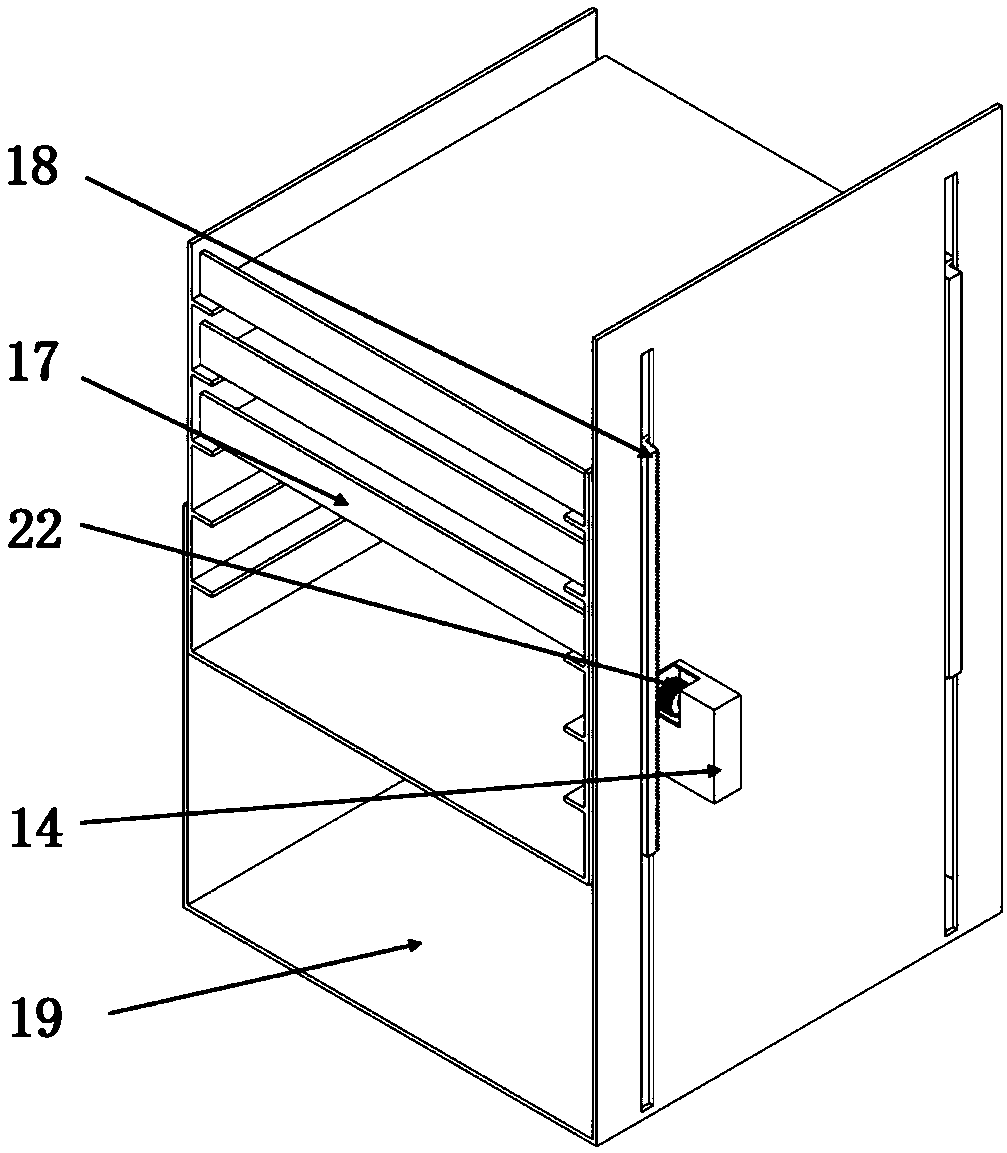

[0022] The object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com