A brake-by-wire device based on DC motor power assist

A technology of DC motor and brake-by-wire, which is applied in the direction of brake transmission, brake, transportation and packaging, etc. It can solve the problems of unfavorable high integration requirements, many parts of the brake device, and large area, so as to achieve failure Good stability, high integration, and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0054] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

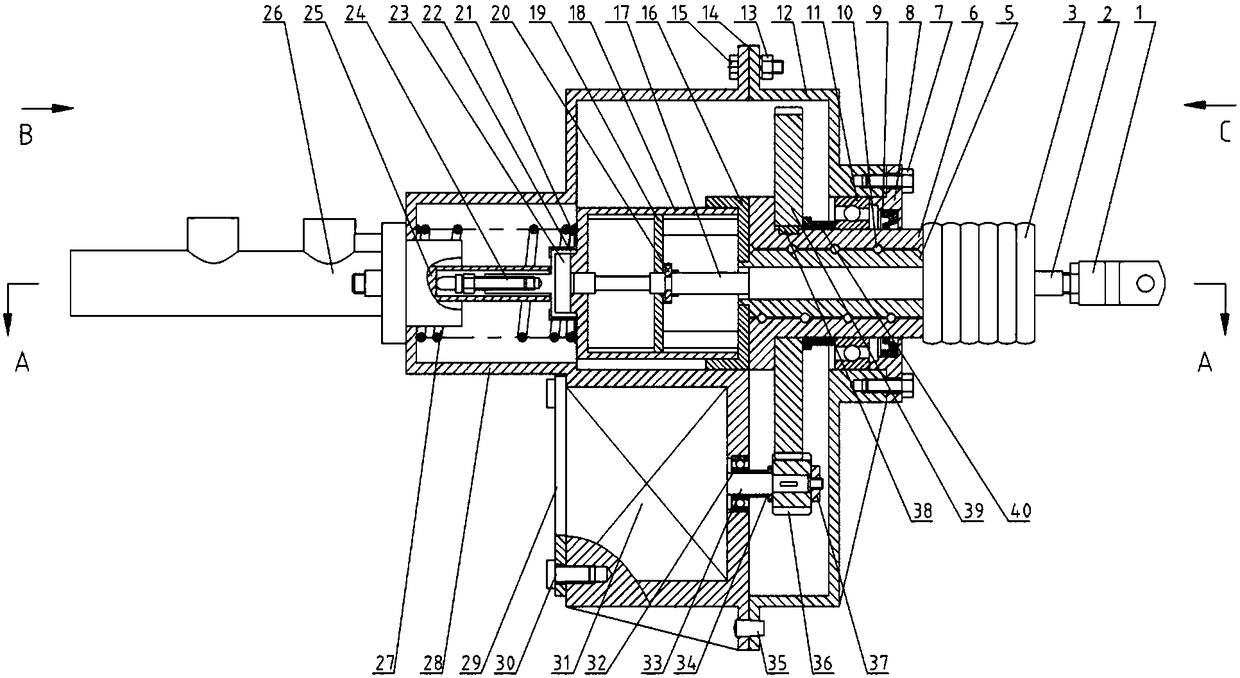

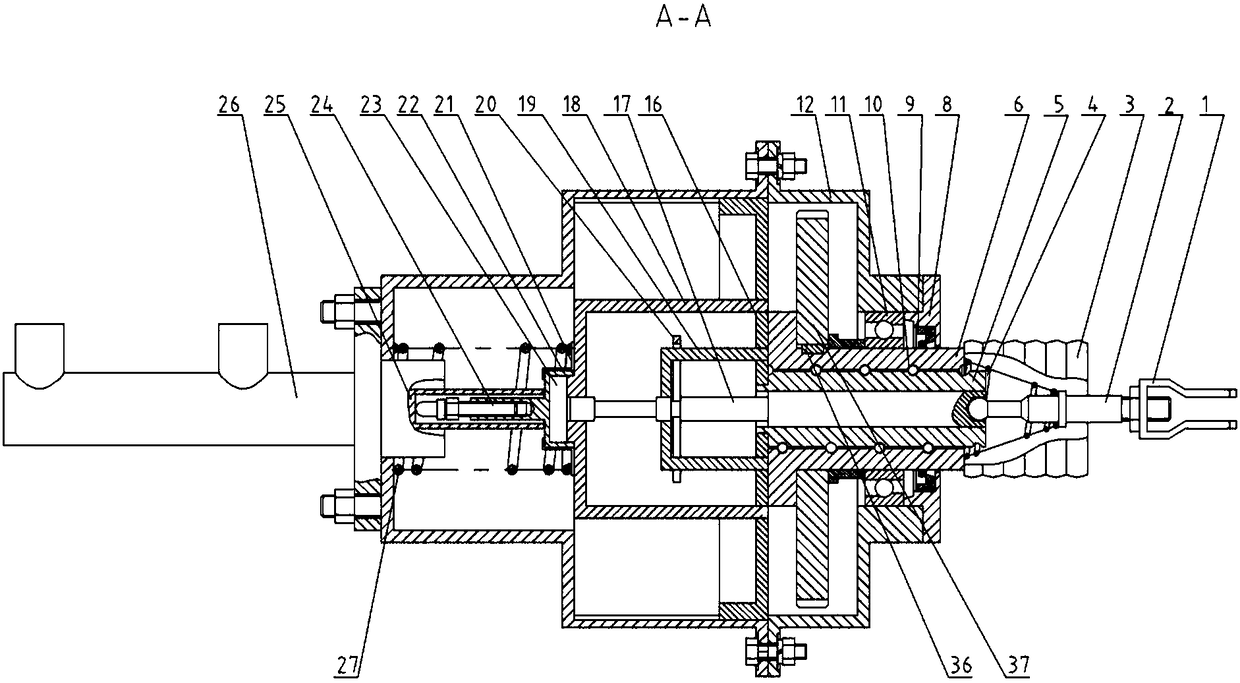

[0055] Such as figure 1 As shown, the present invention provides a brake-by-wire device based on a DC motor, the brake-by-wire device is installed between the brake pedal and the brake master cylinder, and is mainly composed of a U-shaped joint 1, a valve stem 2, a valve Rod return spring 4, roller screw screw 5, ball screw nut 6, rear housing 12, valve body seat 16, pedal lever 17, valve body 18, pedal support 19, locking plate 20, master cylinder push rod Seat 22, rubber buffer block 23, master cylinder push rod 24, master cylinder piston rod 25, brake master cylinder 26, master cylinder push rod return spring 27, front housing 28, DC motor 31, pinion 36 and bull gear 39 compositions.

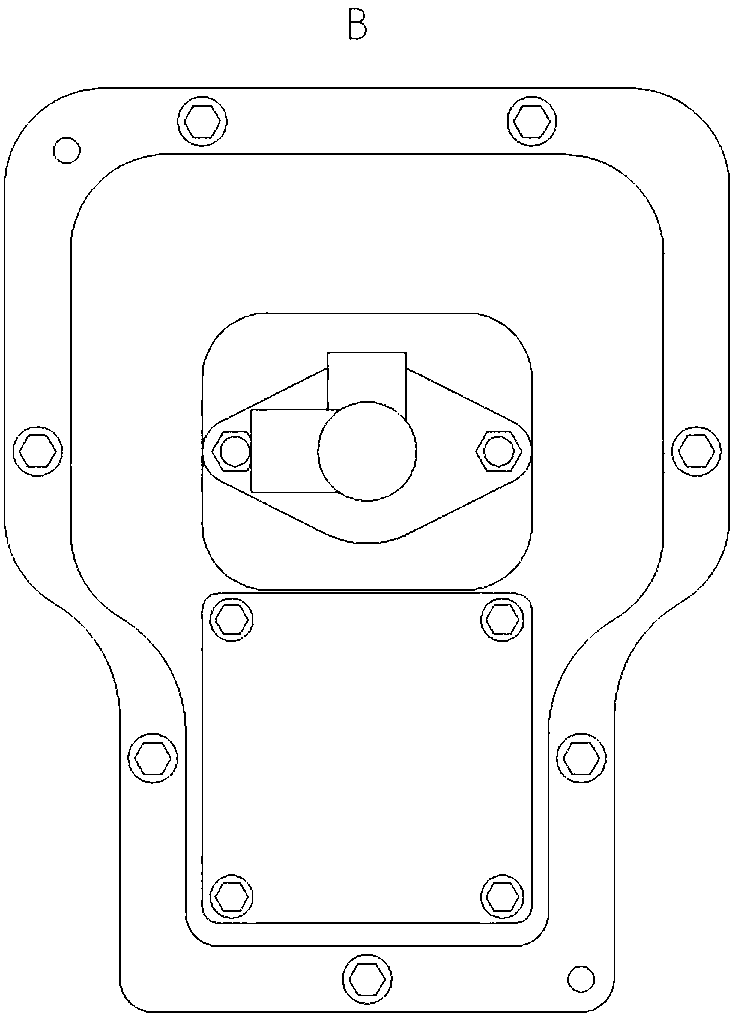

[0056] Such as figure 1 and Figure 5 As shown, the rear housing 12 and the front hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com