A flue gas desulfurization device and method

A desulfurization device and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems affecting the continuity and work efficiency of flue gas desulfurization, improve desulfurization efficiency and continuity, and avoid direct contact , the effect of avoiding the loss of waste heat of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

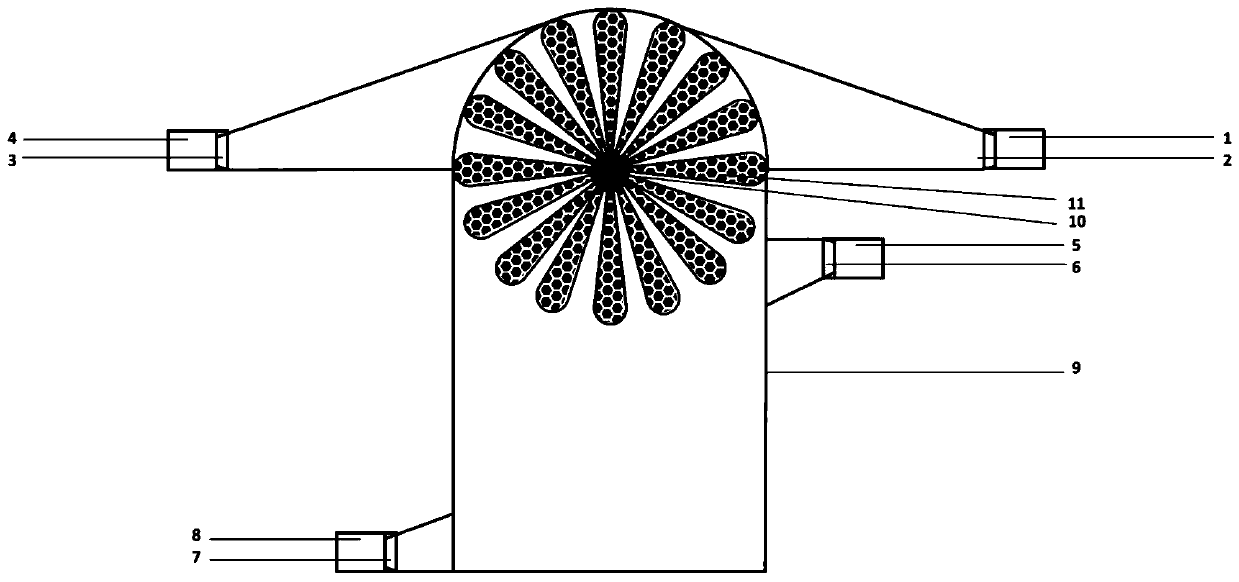

[0031] see figure 1 , the present invention includes a casing 9 with a semicircular structure at the upper end and a central shaft 10 arranged at the center of the bottom of the semicircular structure in the casing. The desulfurization impeller 11 is installed in the casing 9 through the central shaft 10. The inner wall of the semicircular structure at the upper end is in close contact; the surface of the desulfurization impeller 11 is a mesh-like structure, which is covered or fixed with activated carbon, activated coal, activated aluminum chloride, which has physical adsorption and chemical adsorption functions for sulfur dioxide. Adsorption materials of zeolite or silica gel, wherein the fixing material is polytetrafluoroethylene or silicon dioxide resistant to sulfuric acid;

[0032] A flue gas inlet pipe 4 and a flue gas outlet pipe 1 with a flue gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com